Engine building is pretty close to an art form. And like any other performance art, it can be learned through experience. Also like an artist, the best tools just make the task that much easier. Over the years, engine building tools have become far more plentiful and built in numbers that also makes them affordable.

In Part 1 of Our Story on Basic Engine Building Tools, we covered the essential tools that anyone would need to accomplish the task of assembling an engine. This time, we’ll cover more of the necessary gear needed to nudge this task closer to the professional level.

Tools You’ll Need to Build an Engine Like a Pro

(We’ll include a complete parts list of all the tools discussed in this article at the bottom of this post.)

Right from the beginning, a solid engine stand is an item that is often overlooked. Once you’ve amassed more tools, you will quickly discover those inexpensive three-legged engine stands that worked when you were just starting out seem even more flimsy and just not up to your new standards. A solid stand capable of supporting 1,000 pounds is not only important, it makes the job of building engines easier.

We found a bolt-together stand from Summit Racing that is not only rated at 1,000 pounds but incorporates a crank mechanism that makes rotating the engine much easier. An all aluminum LS engine may not need this feature, but an iron-headed big block Chevy can be a tussle to rotate the assembly, especially with the engine inverted.

In Part 1 of Our Story on Basic Engine Building Tools, we acknowledged that investing in a complete set of quality micrometers and a dial bore gauge was clearly a big step. But if you’re serious about building engines, these precision measurement tools are an absolute requirement. The most troublesome step in assembling an engine, once the machine work is finalized, is precisely measuring bearing clearance. This is one step that cannot be ignored without unfortunate and expensive consequences.

Look for a micrometer set that is accurate to 0.0001 inch. There are cheap micrometers on the market but don’t be tempted. It is best to spend the money for precision tools. In dial bore gauges, the same accuracy is required with measurement capability down to the same 0.0001 inch. This is ten times the precision of the less expensive tools that only go to 0.001 inch. It should be obvious why this is necessary.

Moving on to the rest of the engine, we’ve found that it saves time to have several dial indicators set up to do specific jobs. For example, we have one dial indicator specifically for deck bridge measurements and another connected to a magnetic base for crank endplay and also for measuring lifter travel when degreeing camshafts. The precision for these gauges can be merely 0.001 inch since tighter accuracy isn’t necessary.

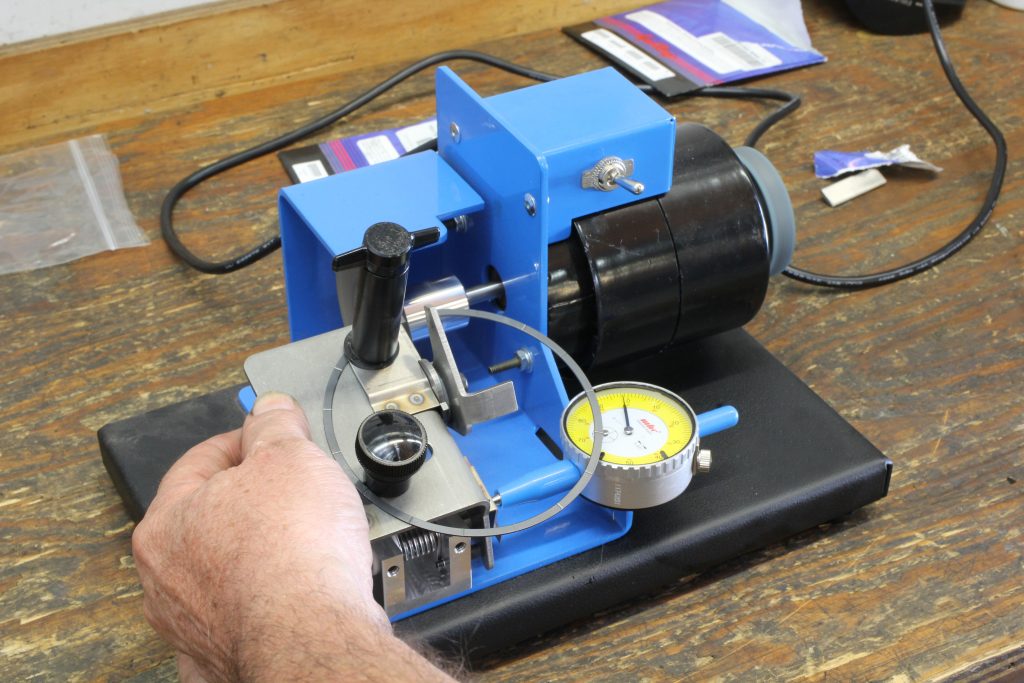

Another eventual decision will come down to sticking with your original manual piston ring grinder or investing in an electric version. We’ll admit that for years, we trudged along with our manual grinder and it served us well. But the time involved with hand-spinning the wheel proved too tedious. We skipped over the intermediate priced electric ring files and went right to the top end Summit Racing Professional Ring Filer, which has turned into one of our favorite tools.

What used to be a boring process is now not only more precise, it requires much less than half the time. The ring filer sets the gap quickly, and also offers a deburring wheel on the opposite side of the motor to remove the bur from each freshly-filed ring end. Yes, this tool is expensive, but if you build more than one or two engines a year it will radically decrease the time it takes to set ring gaps on custom engines. It’s well worth the investment.

Camshaft degreeing is another area where precision is an important part of the game. There are probably a dozen small eight inch diameter camshaft degree wheels that will certainly do the job.

If you already have one you may consider one of the larger professional wheels as an unnecessary luxury. But try this test on your existing wheel. Place the wheel on a large piece of cardboard and mark all four 90 degree positions with a pen. Then rotate the wheel a certain amount, like 14 degrees. Then check all four positions to see if they all report a difference of 14 degrees. If not, then your wheel is not accurate and should be replaced.

By using a larger wheel, especially one machined instead of printed, there is enough space in between the hash marks to improve accuracy.

Other tools that we use all the time are three jaw pullers for crank timing gears as well as dedicated harmonic balancer pullers. You can’t even begin to work on an engine until the harmonic balancer is removed and there are multiple tools that will do the job. For example, Summit Racing offers multiple harmonic balancer puller and installer tools for older engines as well as a dedicated tool for stock LS engines. If there’s enough reader interest, we could write a full story on just dedicated tools for LS engine building as these engines demand their own specific assembly tools—let me know in the comments if you’d like to learn more about that topic.

Rod bolt stretch gauges are another individual piece of kit for your collection that we consider an essential assembly tool for mid- to high-end engines. Stock rod bolts merely use a torque spec that millions of production engines have proven to be sufficient. But higher rpm performance engines demand better rod bolts and those generally are spec’d with both a torque number as well as a rod bolt stretch number. This stretch number is a far more accurate way to establish the proper clamp load on a rod bolt—but this requires a specific use gauge to measure.

Frankly, in our opinion, this is the only way to assemble a performance engine. Summit Racing offers a very affordable analog dial indicator stretch gauge as does ARP, but if you really want to be high tech, ARP now offers a digital stretch gauge that reads to the fourth decimal place (0.0001 inch).

We have not included a ton of cylinder head assembly tools but among the most useful is a valve spring height mic if you prefer to assemble your own heads. This little tool makes setting the installed height between the spring seat and the valve spring retainer simple and quick. One thing we’d mention is that after using this tool for many years, we used a dial caliper to check its accuracy. This led to the discovery that our height mic has induced an error of 0.020 inch.

Accuracy Counts!

One last tip to fall under the precision tool category is that you should periodically check your gauges for accuracy. Clicker torque wrenches, micrometers, dial bore gauges, dial indicators, and any other precision measuring tool can fall out of calibration after years of use. It doesn’t do any good to use precision tools if the results are not accurate. This is why quality micrometers include dedicated standards to allow you to check the accuracy of the micrometers. It’s the old adage: “Trust, but verify”.

You may enjoy this article: How to Check the Calibration of a Clicker-Style Torque Wrench

It is beyond the scope of this short tech piece to deliver every engine building tool possible mainly because there are so many and the size of this family of tools keeps expanding. But once you are serious about building engines, you will quickly figure out which tools are essential to the task.

Besides, as hot rodders, who doesn’t like buying tools!

***

Advanced Engine Building Tool List

- Summit Racing Engine Stand – SUM-908300GA

- Powerhouse Products Outside Micrometer Set – POW-152006

- Summit Racing Dial Bore Gauge – SUM-900041-01

- Summit Racing Non-Adjustable Piston Ring Compressor, 4.030″ – SME-904030

- Performance Tool Adjustable Band Ring Compressor – WMR-W89410

- Summit Racing Cam Degree Wheel – SUM-G1057-16

- Summit Racing Cam Degreeing Kit – SUM-G1056-16

- Proform Professional Billet Aluminum Degree Wheel – PRO-67490

- Summit Racing Piston Stop (heads off) – SUM-900191

- Summit Racing Piston Stop (heads on) – SUM-900189

- Summit Racing Magnetic Base and Dial Indicator Kit – SUM-900016-1

- Summit Racing Dial Indicator Stand/Deck Height Bridge – SUM-900061-S

- Summit Racing Rod Bolt Stretch Gauge – SUM-900015

- ARP Rod Bolt Stretch Gauge (analog) – ARP-100-9942

- ARP Rod Bolt Stretch Gauge (digital) – ARP-100-9943

- Summit Racing Universal Piston Ring Filer – SUM-906795

- Summit Racing Electric Piston Ring Filer – SUM-906797

- Summit Racing Pro Ring Filer – SUM-970001

- Summit Racing Piston Ring Squaring Tool – SME-906002

- Performance Tool Harmonic Balancer Puller & Installer Set – WMR-W89711

- Cal-Van Tools 3-Jaw Puller – CAV-952

- Summit Racing Connecting Rod Vise – SUM-906790

- Performance Tool Piston Ring Installation Tool – WMR-W80575

- Summit Racing Oil Pump Primer/Pre-Luber for SBC/BBC – SUM-901015

- Summit Racing Economy Cylinder Head CC Kit – SUM-980180

- Proform Professional Cylinder Head CC Kit – PRO-66831

- Summit Racing Valve Spring Height Micrometer – SUM-900032

- Summit Racing Rocker Arm & Lifter Organizer Tray – SUM-900013

Comments