I am going to build a Chevy 292 inline 6 next year. I was wondering if a 10:1 compression ratio would be too high for 87 octane? Could the timing be adjusted or a higher overlap cam be used to bleed off a little static compression? A little water added to the gas? I will be using this engine to cruise in a 1966 C30 1-ton dually and pull a travel trailer occasionally. Thank you.

D.T.

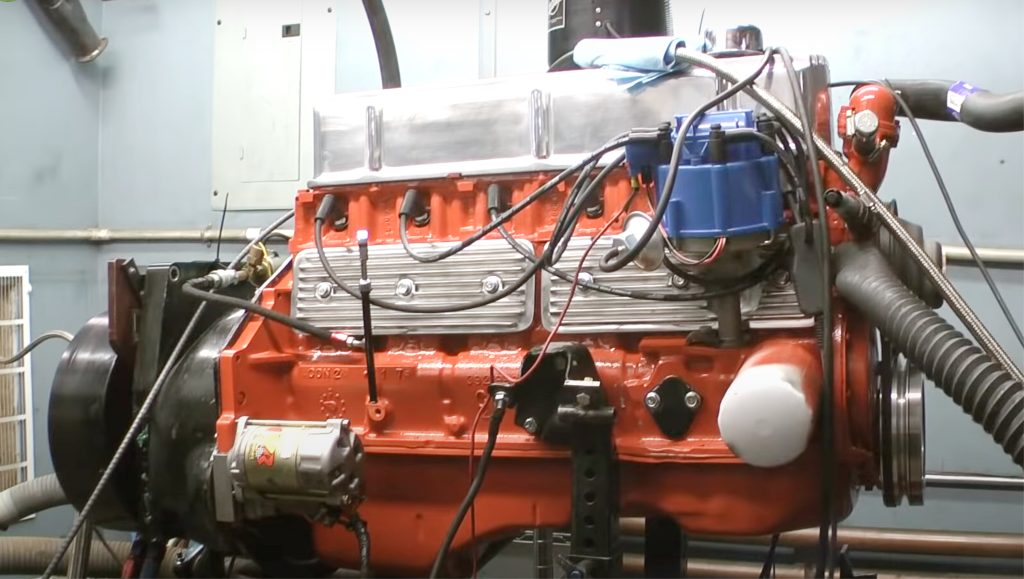

For a quick answer to your question, I think that a 10:1 compression ratio will be too high to run on 87 octane fuel. It might run without detonation on 91 octane but with an older chamber design I think this will be somewhat too high by perhaps one full point. Somewhere between 9.0:1 and 9.5:1 would work.

As a 3.875 inch bore and a 4.125 inch stroke, the 292’s long stroke helps it make decent torque. This along with its near 300ci size will help it when pulling those heavy loads.

You may also enjoy this article: The Pros and Cons of the Chevy Inline Six for Old-School Hot Rods

Consider Improving Airflow Instead

I will assume you are trying to maximize fuel mileage with the idea of 10:1 compression. What you might consider instead is to improve cylinder filling by enhancing airflow with some cylinder head modifications. The stock 1.72 inch intake valves could easily be expanded to 1.84 or possibly even to a 1.94 inch small block Chevy valve. There is a company 12bolt.com run by Tom Lowe that specializes in, yes, GM 12-bolt rear ends but also offers a wealth of 250ci and 292ci inline Chevy six cylinder engine parts and expertise.

If these larger valves sound like a good idea, it would also help once the valve seats have been expanded to carefully blend the sharp edge underneath the valve seat into a nice radius. This is a simple job that might take 30 minutes with a small rotary hand grinding tool for all the valves. This will improve intake and exhaust flow slightly as long as you don’t get aggressive. Just make a gentle radius underneath the valve seats.

Another technique that does not require much effort but pays off in dividends is placing a 30 degree back cut underneath the 45 degree seat angle on the intake valves. This helps radius flow between the seat and valve and has been proven to improve low-lift flow with no detriment to higher lift flow.

More Chevy Inline 6 Engine Performance Upgrades

If you want to further upgrade your 292, 12bolt.com also offers kits with the valves and guides and other components ready to install. If you want to go deeper into the cylinder heads, Lowe also offers a cylinder head modification called The Lump. This involves removing the cylinder head bolt boss from each shared intake port. This leaves a bolt head in the floor of the intake port that is covered by a cast aluminum radius that is called the Lump. Lowe’s website has posted flow numbers on the improvement and the gains are significant. The stock head bolt hole in the top of the head is drilled and tapped to be sealed with a plug that can be removed to access the head bolt in the intake port.

We looked into pistons for these engines and all the stock replacement versions use very thick 3/32 inch (0.0937) thick top and second rings. Small block Chevy engines from back in the day used 5/64 inch (0.0781) top and second rings that are now considered to be thick, clunky, and not desirable. So your engine is burdened with even thicker rings that will generate some significant friction compare to modern ring packages such as current LS engines that now use 1.5mm or 1.0mm thickness (1 mm = 0.039 inch).

12Bolt.com offers custom-built Ross pistons for a 292 that are not specified but will most likely be offered with 1/16 inch (0.0625 inch) thick top and second ring package that would dramatically reduce friction. These pistons are much more expensive than stock replacement pistons so that might be too high a price just to improve engine efficiency but it’s a step in the right direction.

There are also several camshafts offered for these engines through 12Bolt.com that you might also consider. Keeping the intake duration short at between 200 to 215 degrees of duration at 0.050 would be wise to enhance low-speed torque. All of these mods will add additional flow into the cylinder and even with a “lower” compression of 9.0:1, the cylinder pressure (torque) will be much better than a stock engine.

Of course the other ideas that go along with improved efficiency would be a more modern four-barrel intake and a set of inline 6 headers that would also improve part throttle performance. The Clifford intakes have been really been the only game in town. 12Bolt.com offers a different idea with its PES four-barrel intake manifold that is commensurately priced but according to 12 Bolt is worth a measurable increase in power over the Clifford.

Another idea worth considering is a better ignition system. Davis Unified Ignition (DUI) builds a dedicated HEI distributor for 230/250/292 inline Chevy sixes that offers a much hotter spark and more reliable ignition timing than those old contact points. This would be our first modification even if we didn’t make any other changes to the engine.

Understanding Water/Methanol Injection

You mentioned adding a little “water to the gas.” We will assume what you meant is using some kind of water injection system for a 10:1 compression street engine. You should never physically add water into gasoline as the two will not mix. The water will merely sit at the bottom of the tank (because gasoline is lighter than water) and the result will eventually cause corrosion in the fuel tank which should be avoided.

Water injection systems can be used on a normally aspirated engine to add a mist of water to the incoming air charge. This is especially helpful on high compression engines to combat detonation under wide-open-throttle (WOT) conditions. Water injection is especially efficient in hot, dry climates with low humidity levels where the water evaporates instantly and reduces the air inlet temperatures. This is the main reason why water injection helps reduce detonation.

Summit Racing offers a Snow water/methanol injection system that is affordable and, while intended for boosted applications, it can be adapted to be used with normally aspirated engines.

We’ve gone quite a bit further with your question than you probably anticipated so the best plan of attack would be to pull up 12Bolt.com and poke around, then contact Tom Lowe with more specific questions. You’ll run across some of his customers including an interesting turbocharged inline Chevy six in a ’65 Chevelle that runs in the 11s!

10:1 Chevy Six Parts List

- Davis Unified HEI for GM Inline 6, DUI-61720RD

- Snow Water Injection System, SNO-201RD

Great truck engine but not so great for a hot rod. Six cylinder Chevy’s are arguably the greatest engines of the 1930’s easily surpassing the Flat Head V8 Ford in durability and smooth performance but the siamese intake ports have always been a hindrance to performance. Shame really.

How do I determine what CID my 6 is it was in my 68 Camaro but is a reman hope to use it in a rat rod one day has a power glide trans

The only in-line 6 that was offered in F bodies was 250 in-line 6. I’m sure there’s others other ways to do this that are probably easier. But I would pull the cylinder head and air some calipers to it and measure the bore. If memory serves none of the in-lines from GM shared the same bore size. I’ve also read that the 292 was to tall to fit in a F body. So at a minimum you can mark that one off the list.