It was Mark Twain who once wrote: “The reports of my death are greatly exaggerated.”

The same could be said about the basic four-barrel carburetor.

We find ourselves well into the second decade of the 21st Century and, by now, everybody was supposed to be in flying cars—and yet the carburetor still flourishes. One major reason for this is simplicity but it doesn’t hurt when Edelbrock invests in what could be termed the next generation racing carburetor.

Despite its external similarities to that brand from Bowling Green, Kentucky, this is a straight from a clean computer screen creation. There are so many changes to the Edelbrock VRS-4150 over the basic square flange 4150 carburetor that this story will require significant length to detail so let’s get started.

For anyone with even a rudimentary knowledge of carburetors, the ability to adjust the carb to meet the individual needs of the engine across a wide band of operation is the best way to build a universal carburetor. The VRS-4150 offers a ton of adjustability built into its design improvements, making this carburetor a source of joy for carb tuners everywhere. .

Carburetor size is always one of the first questions and the VRS-4150 is currently offered in three sizes: 650 cfm, 750 cfm, and 850 cfm, exclusively in a mechanical secondary configuration. The carburetor offers four-hole idle adjustment and, as we will detail in a moment four separate metering circuits as opposed to the more traditional two standard circuits in most other carburetors.

Exploring the Outside of the VRS-4150 Carburetor

Visually impressive, the VRS-4150 offers a single casting design that incorporates the throttle plate with the main body, so there’s no gasket or attaching screws. The main body is also a half inch taller than a typical 4150 which tends to help stabilize fuel delivery. The throttle plate also incorporates a multi-position flange that can accommodate either a 4150 or a 4500 style manifold pattern.

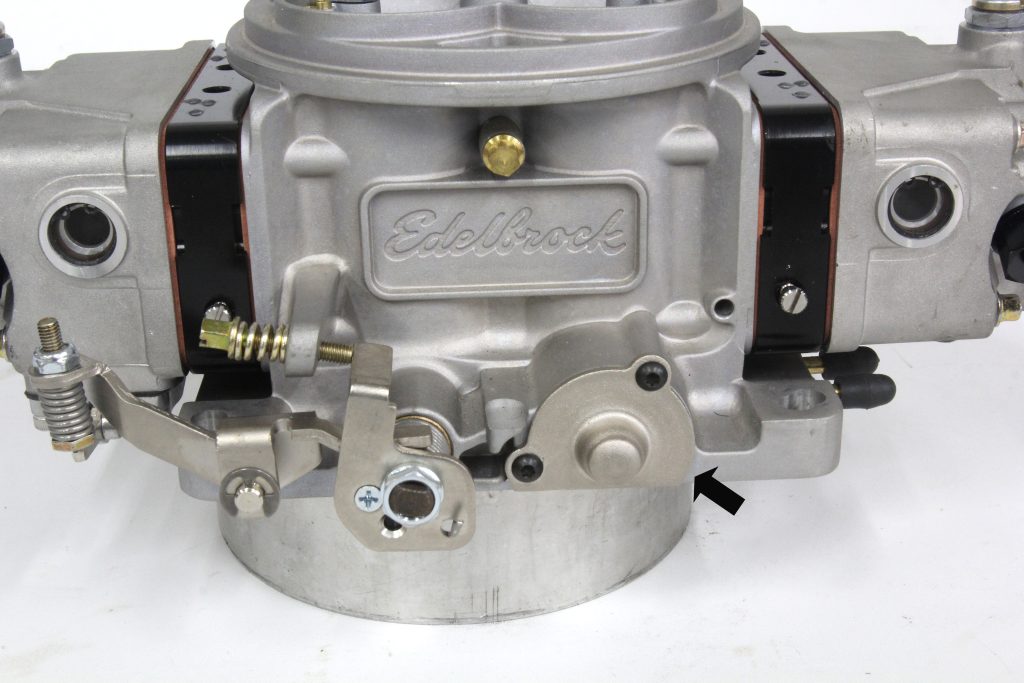

Keeping with the external features, the float bowls feature large, clear glass sights for setting float levels along with separate bowl drain plugs that are handy when changing jets. In addition, the bowls offer the ability to plumb fuel from either side. There are also both large and small vacuum ports extended from the front and rear of the throttle plate. The throttle linkage is also drilled for both 200-4R and 700-R4 TV cable linkage fittings as well as the kick-down linkage provisions for the TH350 transmissions.

Among the most useful additions to the Edelbrock VRS-4150 is the pair of idle bypass adjustment screws located on both sides of the main body. These adjustment screws offer the ability to set curb idle speed instead of using the throttle stop on the linkage. Idle bypass is especially important for competition and hot street engines with long-duration camshafts and very low idle vacuum numbers.

By using the idle air bypass circuit to set idle speed separately, this allows the throttle blades to remain in their ideal position relative to the idle transfer slot. This bypass circuit eliminates the need to drill holes in the throttle blades to create sufficient inlet air into the engine when low idle vacuum requires a less restrictive inlet for idle speed.

Another nice feature is the built-in fixture on the passenger side of the throttle body for the addition of a throttle position sensor (TPS). This can be useful for either data logging to ensure wide-open-throttle (especially in road course of autocross applications), or it can also be used to establish TPS signals for electronic automatic transmissions like the 4L60E/4L80E.

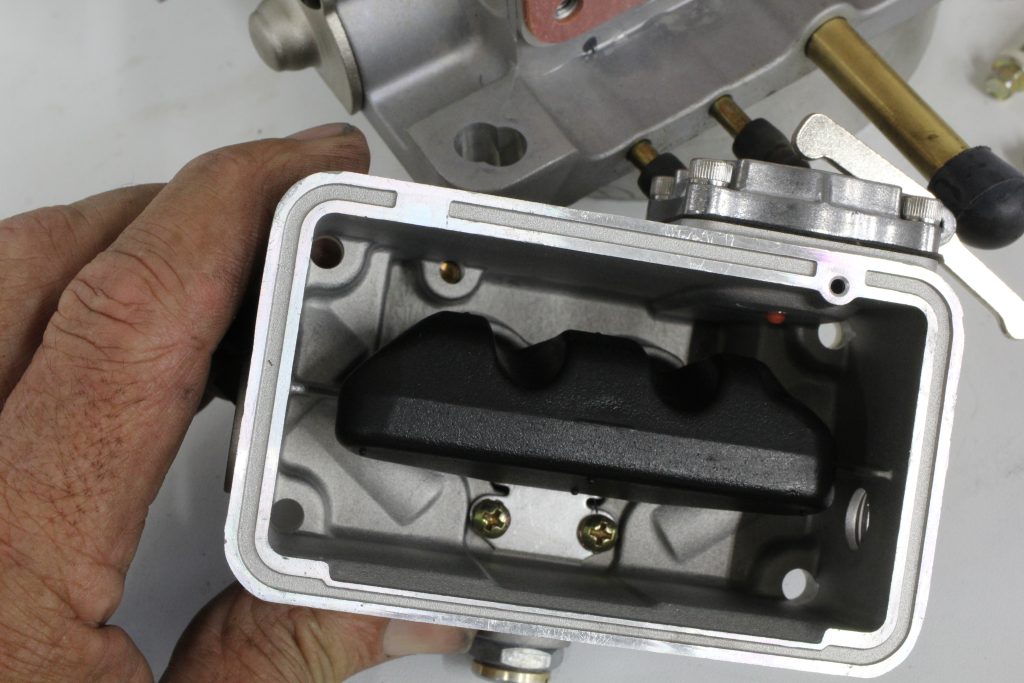

A Look Inside the VRS-4150 Carburetor

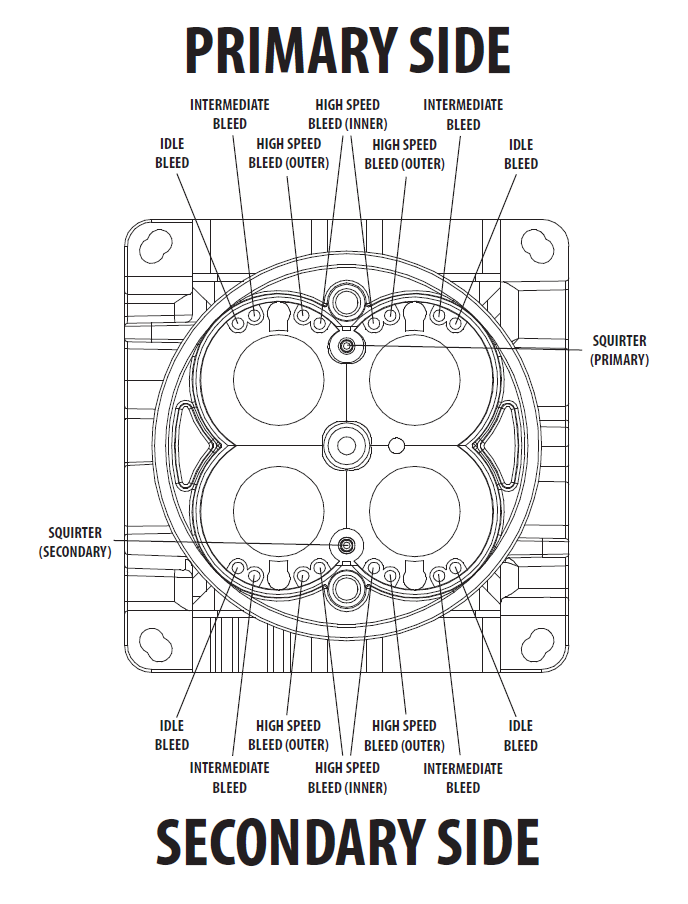

With most of the exterior features covered, we can get into the heart of this carburetor and detail the four metering circuits. A typical 4150 and many 4500 carburetors use a two circuit system. One is for the idle side with the other for main metering. These carburetors can be identified by the two air bleeds normally found on the corner of each venturi in a typical 4150 carburetor.

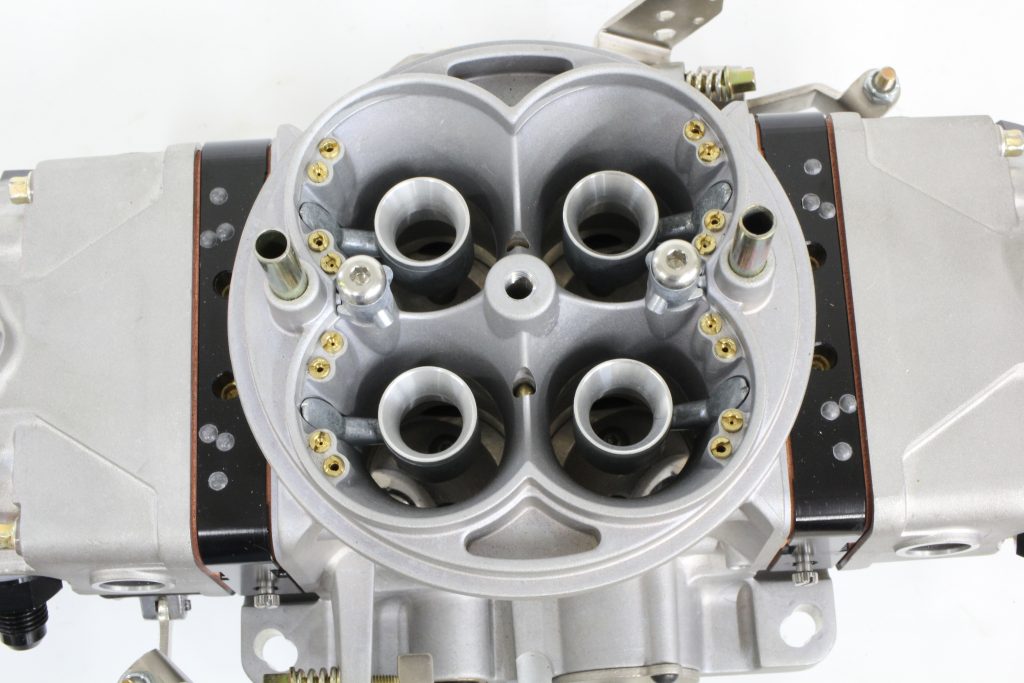

By looking down through the top of the VRS-4150, you will instantly be greeted by four separate screw-in adjustable bleeds for each venturi on the carburetor. These are delineated from the outside toward the inside of each venturi as the idle/transfer slot, intermediate, low-speed main metering, and finally high–speed main metering circuits. Each of these circuits exercise control over a separate portion of the overall fuel delivery curve.

It’s really not as complex as it sounds.

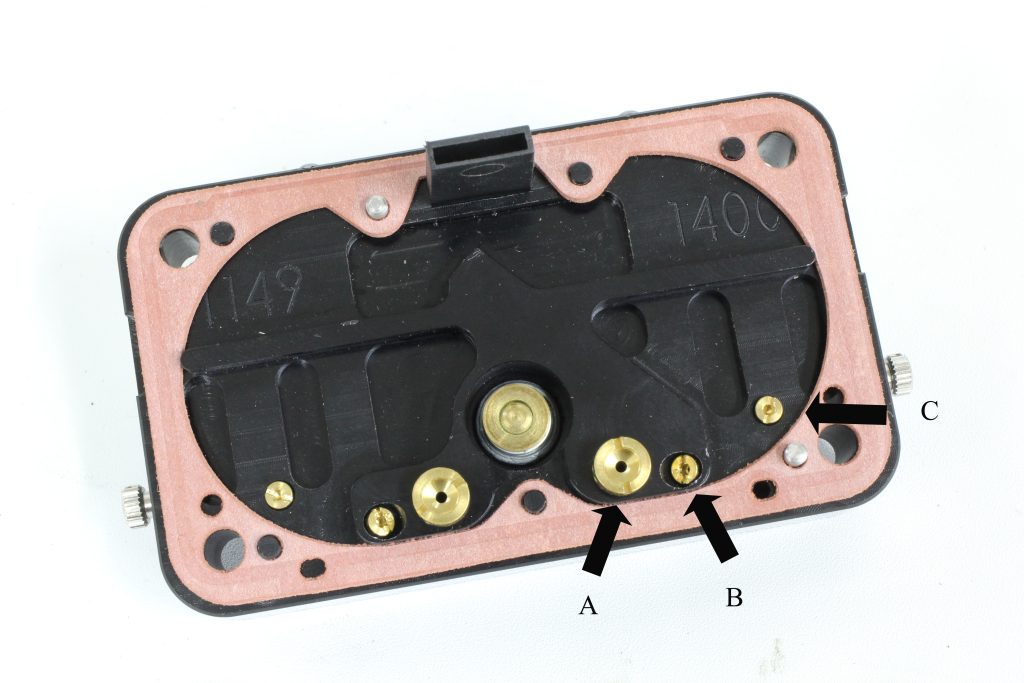

The idle and transfer slot portion controls exactly what the description infers. The amount of fuel delivered is controlled by a small screw-in jet located in the main metering block. The air bleed located on the top of the carburetor controls the amount of air and is generally balanced in size with its corresponding fuel restrictor.

The intermediate circuit could be considered the more independent circuit of the four. The intermediate circuit was first added to older Holley Dominator carburetors and were assigned the term three-circuit carbs. Instead of supplying additional fuel through the boosters, the intermediate circuit employs a separate discharge tube that exits from the wall of the venturi roughly halfway between the booster and the throttle blades.

The Edelbrock VRS carb uses an individual fuel jet located on the float bowl side of metering block for each venturi on the carburetor. This circuit tends to be more velocity sensitive.

As an example, if the entire fuel curve is slightly lean, increasing the intermediate circuit jet size will add more fuel at the top end of the rpm curve (let’s say from 5,000 to 7,000 rpm) as opposed to the entire curve including the bottom half from 3,000 to 5,000 rpm.

Plus the original single main circuit has been expanded into two. This pair splits the fuel delivery curve into low-speed and high speed areas. These emulsion circuits operate more closely to a typical performance carburetor. So by changing bleeds in each circuit the carburetor can more accurately achieve the engine’s ideal air-fuel mixture curve.

The final circuit is the idle side that operates very similarly to all other idle circuits in terms of using an idle feed restrictor and an idle air bleed on the top of each venturi. So with an idle, low-speed main, high-speed main, and an intermediate circuit, we have our four circuit carburetor.

The beauty of this much circuitry is that very finite changes can be made to adjust the fuel curve. This of course, points this carburetor as intended mainly for serious competition use but also offers the veteran carburetor tuner the ability to make finite changes to the fuel curve over a broad rpm operating range. While these kinds of tuning options have been available in the past, they were the result of serious modifications by professional carburetor modifiers. Now much of that customization is available in an off-the-shelf performance carburetor.

A design with this many improvements often also calls for unique parts, but the good news is that many standard 4150 replacement and tuning parts like main jets, bleeds, and power valves are completely interchangeable.

We may not yet be in the age bubble-top, cartoon Jetsons flying cars just yet but we have definitely arrived when it comes to 21st Century tunable carburetors.

Edelbrock VRS-4150 Carburetor Specs

| Part Number | CFM | Venturi Dia. | Throttle Blade Dia. | Booster |

|---|---|---|---|---|

| EDL-1306 | 650 | 1.250″ | 1.6875″ | Standard |

| EDL-1307 | 750 | 1.375″ | 1.6875″ | Large Annular |

| EDL-1308 | 850 | 1.390″ | 1.7500″ | Annular |

I have a 1976 Pontiac Trans Am , 400, Auto, what type of carburetor will work with my engine?

Hey Eddie, Click here to contact the Summit Racing tech folks. They’ll ask you a few questions on your particular setup and suggest a good carburetor that’ll work well with your T/A.

I have a Pontiac 400 Bored 30 over With a 425 stroke With heads that are flowing 340

Sounds like a major improvement over the previous carburetor

Will follow to see how it works out

I had a webber with a three circuit tune ability when I got it right I had a hard pulling midrange and that’s were Harley’s like to pull I like the new carb have a little bit of how to tune it gust a little!

I have the 650cfm carb on my 78 bronco with headers and sidepipes. It’s awesome! All my friends told me I was dumb for buying a “race” carb with no air horn or choke. They can sit and watch me make mud rainbows while holding their ears. I love this thing. The tunability is insane. I am very close to stock settings at the moment.

I have 65s in front and 66s(stock) in rear. I added some 0.55″ PVRC on the primary metering block. I will most likely open the secondary PVRC up a bit. I pulled the stock 4.5 PV and put 6.5 front and rear.

My primary PV was unmetered – I bought pin vice, jet blanks and make tiny jets. It worked great and I’m continuing the tuning process. I can make a jet change in 15 mins now. More to come.

https://rumble.com/v37y5qz-edlebrock-vrs4150-edlebrocks-new-double-pumper-race-carb-on-a-78-bronco.html

Did holleys patent expire? However always into anything that is a improvement so lets see what happens?