In the context of automotive vehicle gauges, a sending unit is how the gauge receives the information it displays. That means most gauges in your dashboard are probably connected to some sort of sending unit—and they don’t always work in the same way.

So with the help of the gauge gang over at NVU Inc., we’ve put together a handy primer that’ll give you some basics on the different types of sending units out there for some common applications: fuel level, oil pressure, and water temperature.

Special hat tip to the NVU tech folks. You can read more in-depth gauge technical resources at their tech blog here.

***

What is a Sending Unit?

As alluded to above, a gauge sending unit is a type of sensor/probe that receives data from the vehicle and sends it to the gauge. There are a handful of different types of sending units, and the phrase “sending unit” is often used as a blanket term to refer to mechanical probes and tubing systems too—we’ll clear all that up in a sec.

In many situations, a sending unit is a transducer, which is a fancy way of saying it turns one form of energy into another. For instance, a microphone is a transducer, as it takes sound and transforms it into an electrical signal. A speaker is a transducer too, only it goes the other way by transforming an electrical signal into sound.

For a vehicle sending unit, the transduction process usually entails transforming heat (for a temp gauge) or a diaphragm movement (for a pressure gauge) into an electrical signal—but not always, depending on the application.

Now that you know the basics, let’s dive into some common types of sending units you’ll find in a typical car, truck, or SUV.

Temperature Gauge Sending Units (Electrical vs. Mechanical)

Typically used for measuring the temperature in your coolant and your engine/transmission oil, a temperature sending unit is a critical part of your vehicle instrumentation. Even if you don’t have a true temperature gauge in your dash, you’ll likely have a temperature warning alarm or indicator light—which still relies on a temperature sending unit to get its data.

For brevity’s sake, there are two types of temperature gauges: electrical or mechanical.

An electrical temperature gauge relies on an electric signal from a sending unit threaded into the engine, which itself is essentially a temperature sensitive electrical resistor. The sending unit is a transducer that, as the temperature changes, sends those variable resistance readings (measured in ohms) to the gauge, which interprets that changing electrical resistance into a temperature reading.*

*Important! Make sure you’ve got the correct sending unit for your gauge—they’re not always interchangeable between brands and vehicle applications. A mismatch can cause inaccurate readings or prevent the gauge from working at all.

A mechanical temperature gauge is a bit more straightforward. It uses a long, sealed tube/hose that’s permanently connected to the gauge, while the other end threads into the motor. The tube contains a fluid that expands and contracts as the temperature changes, which ultimately moves the needle in the mechanical gauge.

While a mechanical temperature gauge doesn’t have an exact sending unit per se, its not uncommon for gearheads to use the term “sending unit” to describe the probe at the end of the sealed tube—so we wanted to make sure to mention the distinction here.

Which type of temperature gauge is better?

We did an entire standalone article on the topic, complete with diagnostic and testing walkthroughs. You can get a more thorough explanation in this story: What’s the Difference Between a Mechanical & Electrical Temperature Gauge? (& How To Test Them)

Pressure Gauge Sending Units

Just like the temperature gauges we talked about above, pressure gauges commonly fall into either mechanical or electrical categories.

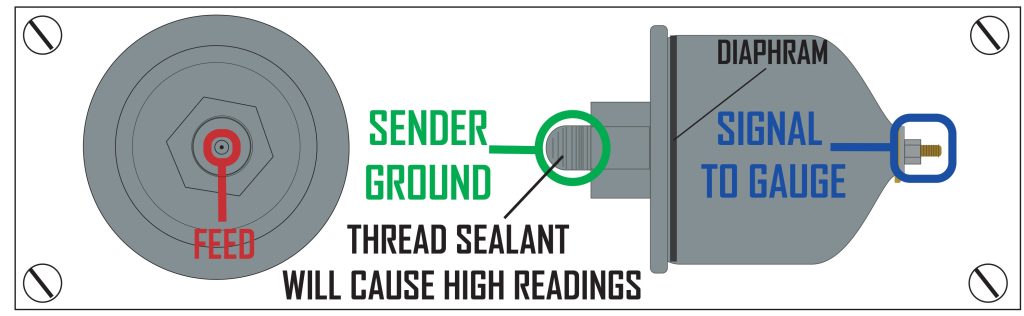

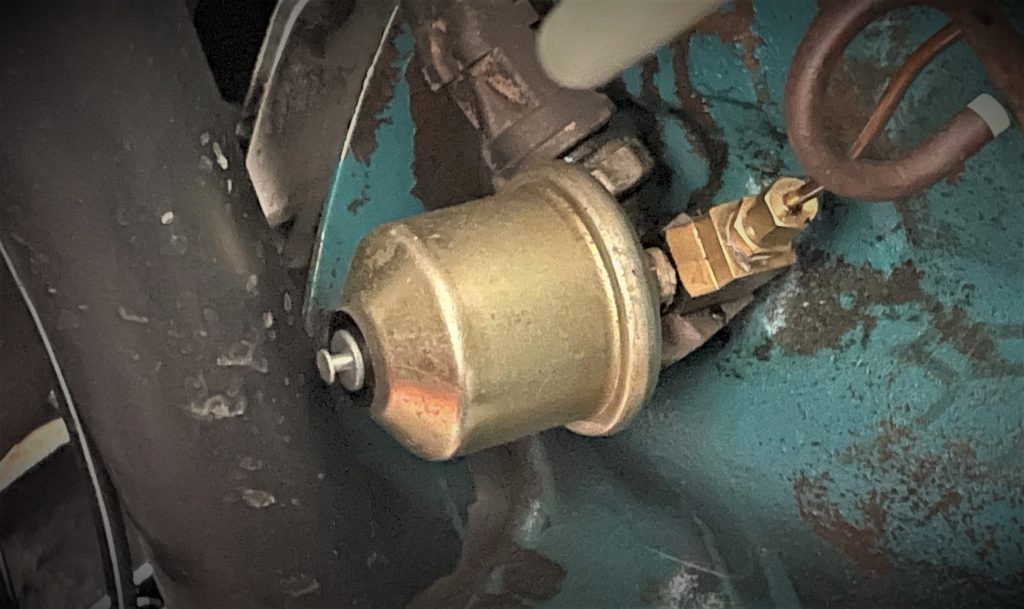

An electrical pressure gauge sending unit, commonly used for oil pressure, is often shaped like a bell. That’s because it houses a small diaphragm that moves in and out as the pressure changes.

The sending unit uses a transducer to change those diaphragm movements into an electrical signal, which is then sent to the gauge to translate into a readout. And again, just like the electrical temperature gauges, you’ve got to make sure the sending unit matches your gauge, or you’ll get incorrect readings.

A mechanical pressure gauge, on the other hand, doesn’t have a sending unit, technically speaking. Instead it relies on a tube that’s plumbed directly into the engine to transmit pressure fluctuations to the gauge for interpretation.

But unlike a mechanical temperature gauge, a mechanical oil pressure gauge tubing system isn’t permanently attached. When you buy a mechanical oil pressure gauge, you’ll typically get a kit that includes all the tubing and fittings you’ll need to hook up the gauge. (If you didn’t, gauge supply line kits are also sold separately.)

Again, even though it’s not technically a “sending unit” here, we wanted to make mention of mechanical oil pressure gauges simply because you may hear the term used to describe the gauge’s tubing system.

Fuel Level Gauge Sending Units

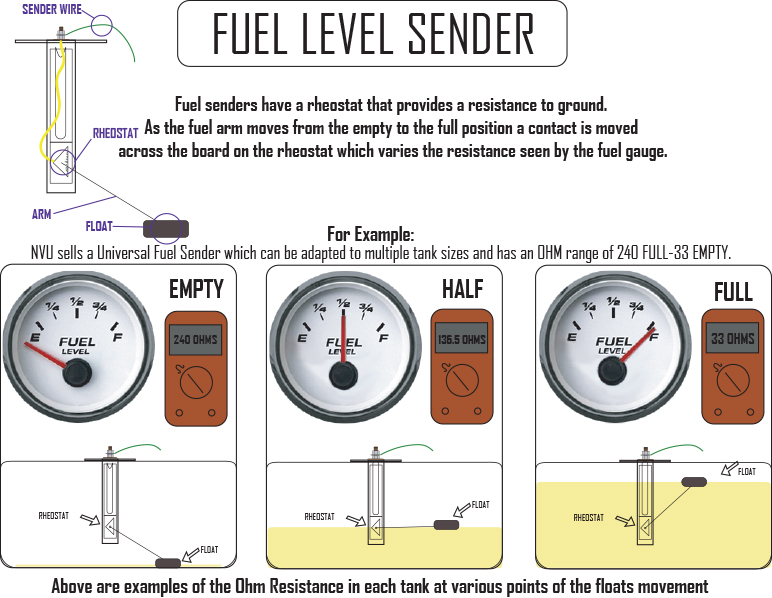

For the most part, a fuel level gauge sending unit can be a bit easier to understand. Typically, it uses a float system that rises and falls with the level of fuel in the tank. The pontoons are attached to an arm which is linked to a rheostat (a fancy term for a variable resistor) that is connected electronically to your fuel gauge.

As the float height changes, the electrical resistance changes too, which is interpreted by the fuel gauge to display your fuel level.

Again, the gauge gurus over at NVU have a great illustration that better explains the process of how variable float height is translated into resistance readings. Check it out:

But just like our note with temperature gauges, you’ve also got to make sure you’ve got the proper sending unit for your fuel gauge—there are many different fuel sending unit variations. In other words, a fuel sending unit for one vehicle may use 130 ohms to reflect a half-full tank, while another may by calibrated to deliver 180 ohms to denote a half tank.

The NVU team made a great video that shows you how a fuel gauge sending unit works and how to troubleshoot and test yours:

Other Types of Gauge Sending Units

This 101-style article only covered the three most common types of gauge sending units. But there are more. Specifically, a lot of modern speedometers and tachometers use a sending unit with a magnetic Hall Effect sensor to monitor rotational speed. You can get a closer look at all of these gauge sending unit designs in this article from NVU Inc.

Another fine article! thanks for sharing

Very informative…Thank You, guys

Hey, thank you guys for reading!