We all know that making big power with an LS is as easy as adding boost, right? In fact, the recipe for huge power is to add cam, springs, and boost. Of course this assumes a number of things like large enough injectors and pump, intercooling and the proper tune (hopefully with E85).

What about the enthusiasts who want to go the all-motor route?

I can hear the turbo crowd cringe, but the reality is that not everyone wants boost. So, we decided to illustrate what it takes to exceed 500 (flywheel) horsepower with off-the-shelf components on a 5.3L LS engine.

Why Choose a 5.3L?

Sure, it would be much easier to produce the desired 500 hp with almost any run-of-the-mill 6.0L (LQ4, LQ9, LY6, etc.). In fact, all it takes is the right cam on a 6.0L, but the problem with the bigger motor is they are more expensive and harder to find. Bigger is certainly better, but so too does it require a deeper wallet.

By contrast, wrecking yards are literally full of base 4.8L and 5.3L engines. On my last trip, I counted over a dozen LR4 and LM7 combos just begging for new homes. Noticeably absent were any 6.0L and 6.2L engines—or any aluminum motors for that matter!

When it comes to availability, the 4.8L and 5.3L LS reign supreme, and since bigger is better, why not start with the 5.3L?

Learn more about each LS engine displacement:

* 4.8L LS Engine Guide: Block Specs, Swap Resources & Build Info

* 5.3L LS Engine Guide: Block Specs, Swap Resources & Build Info

* 5.7L LS Engine Guide: Block Specs, Swap Resources & Build Info

* 6.0L LS Engine Guide: Block Specs, Swap Resources & Build Info

* 6.2L LS Engine Guide: Block Specs, Swap Resources & Build Info

* 7.0L LS Engine Guide: Block Specs, Swap Resources & Build Info

500 HP 5.3L LS Engine Block

Truth be told, our test motor did not come from a junkyard, but instead was supplied by the good folks at Strictly Performance. The boost-ready motor was perfect for the intended purpose (we originally planned to run a Big Bang Test on it), but prior to running boost (actually during), we took the opportunity to test out the big Stage 4 cam from Summit Racing.

Though new (or rebuilt), the Strictly Performance 5.3L featured a stock iron block and cast crank combined with production Gen. 4 rods (which we’ve previously taken to 1,543 hp!) and hard anodized, cast pistons.

Think of the short block as a boost ready stock bottom end…sort of.

500 HP 5.3L LS Cylinder Heads & Valvetrain

To help make power, the SP 5.3L also featured a set of ported 706 heads. Katech provided the porting for the 706 heads, though the porting program retained the factory valve sizes. Given our sizable cam choice, the Katech 706 heads were also treated to a dual valve spring package from Brian Tooley Racing, stock rockers, and hardened Trend Pushrods (7.35 inch).

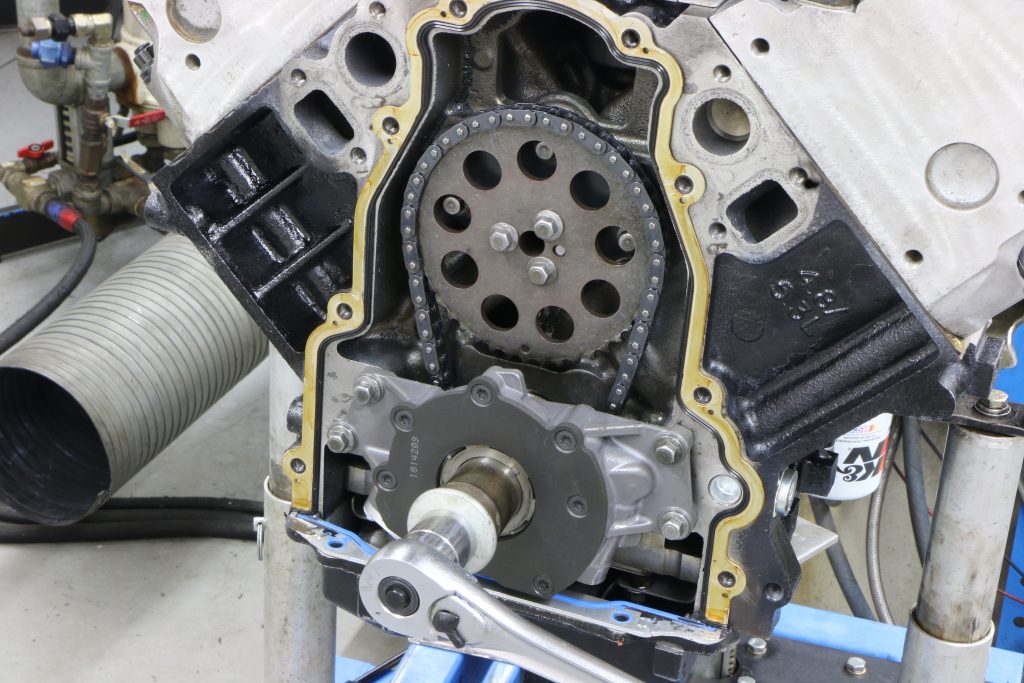

The 5.3L from Strictly Performance was finished off with the same components you might find on any junkyard motor, including a truck oil pan and pickup, front and rear cover, and matching valve covers. While swapping out the LS9 cam used for a previous test, we also replaced the factory damper with an eight-rib unit from ATI to later work with a Vortech Supercharger.

While the SP 5.3L differed slightly from your run of the mill junkyard 5.3L, the mods performed to the motor would certainly work just as well on any 5.3L LS. Simply having a 5.3L is one thing, but having a 5.3L that exceeds 500 hp is another animal altogether. The 5.3L from Strictly Performance already had one advantage, in the form of the Katech ported 706 heads.

You see, the route to improved performance goes through the Big Three, otherwise known as the heads, cam, and intake!

500 HP 5.3L LS Camshaft & Intake

With additional head flow already at our fingertips, all we need to do was address the intake and cam timing. Wanting big power, we selected a Stage 4 cam from Summit Racing, part number SUM-8711R1.

Part of the Summit Racing Pro LS Cam lineup, this Stage 4 option offers a .625/.605 lift split, a 234/247 degree LSA, and a 113+3.5 LSA. Consider this at or near the limit of available piston-to-valve clearance when it comes to running it with a piston that does not have available valve reliefs! The cam not only allowed plenty of breathing to take advantage of the extra airflow offered by the ported Katech heads, but also plenty of rpm to help reach our desired 500 hp mark.

Finishing off the terrible trio was a FAST LSXR intake manifold and matching 102mm Big Mouth throttle body. Considerably more powerful than the factory truck intake, the FAST model offers more peak power along with a healthy torque curve (courtesy of its long runners).

Finishing & Dyno Testing the 500 HP 5.3L LS

With our FAST LSXR intake and throttle body, ported Katech heads, and Summit Racing Pro LS Stage 4 cam, the SP 5.3L was really coming together.

The finishing touches included new lifters, plus fuel rails and 75 pound injectors from FAST, along with a set of 1-7/8 inch, long tube Hooker Headers. The headers were run with collector extensions to help simulate a complete exhaust, but mostly to enhance torque production down low.

The basic SP 5.3L was given a break-in procedure long ago, and required only tuning to start making some serious power. Running a Holley engine management system, we dialed in the air/fuel mixture (12.9:1) and timing curves (29 to 30 degrees total at the horsepower peak).

We were eventually rewarded with peak numbers of 508.6 hp at 6,700 rpm and 435.7 lb.-ft. of torque at 5,700 rpm.

The specific (peak hp) output of 1.568 hp per inch was impressive, but so too was the fact that the modified 5.3L offered a broad torque curve. Torque production exceeded 400 lb.-ft. from 3,800 rpm all the way out to 6,700 rpm!

Not only did the HCI 5.3L offer impressive peak power and torque numbers, it delivered a broad, usable curve you could enjoy without having to ring it out for all it’s worth! After the test of this 500 hp, all-motor 5.3L, there were literally High Fives all around!

Keep up the good work Richard. I watch all of your videos .

My engine is worn out 5.3L chevy Avalanche, I want to rebuild for forged pistons , oil pump, rings, valves, springs, etc.. bolt on the following: 1 – Fast LSXR intake with 102mm big mouth throttel body 2 Katech port LS1 truck 862,706 heads, finish it off with hooker headers long tube. leaving stock fuel rails, injectors, cam, etc.. would this give me the desire punch I want when stepping on the gas while keeping with in a modest budget? (novice who wants more than just stock)

Without a cam or boost the bigger intake is a waste. Forged pistons also a waste. Put a cam in it and port the heads, plenty of power right there. Don’t need the bigger intake or bigger throttle body. Very small gains with those alone.

I totally agree with you. I think you could get away with and be way cheaper with a TBSS/NNBS intake and a 90mm throttle body.

That’s cool I have always be a all throttle mo bottle man. I like the NA build nut I would love more information like what’s factory compression ratio. Did 402 heads change compression ratio. And for people like me that has limited funds I would love a comparison test with the truck intake and throttle body. Then they mentioned the stage 4 cam will require a substantial torque converter. What about a stage 3 cam. Something say street strip daily driver ? Thanks jeff

Hey Jeff Jeff here. I would love to know as well how much did it cost but I would also like to know if u can get stock 402 heads what there off of or if there special made head

I want to know how much does a500 hp5.3 engine cost

I have a similar build that I believe needs proper tuning. Lm7, gen 4 pan, 1219 springs, BTR pushrods and rocker trunnion kit, summit 8707 cam, 1 7/8 longtube headers, tbss with 92mm tb, rebuilt 706 heads stock specs. But it only made around 380whp and 390wtq.. feels like it has no low end torque till about 4500… Even in a 2800lbs car with 3.73 ford 8.8 rear gear.

Ok so much money would this build cost to get 500hp?

How much would this build cost heads and all

How much would it cost to build LS motor to get 500horsepower

Please i need information how reprogram conversion 5.3 to 6.2 on 2013 chevy solverado.

Where are you located

On a 2013 you can just get someone with HPTuners to download you a stock tune for a 2013 6.2 from the tune repository and overwrite the 5.3 tune on your computer. Then the tuner can adjust for any modifications you have made to the engine.

For the extra money of the fast intake and the throttle body and ported K heads you could have found that 6.0/LS3 top end or a 6.2, swapped a cam and made and extra 50/70 h.p. than what you made with the crap 5.3…

They said they wanted to use 5.3 because there more readily available didn’t you read that ? Come on man pay attention lol

John just came here for attention! Compensating or something! 🙂

Or buy a $250 tbss and $100 92mm tb for about 15 less hp and 1/4 of the cost..

And obviously don’t use a impact to tighten up the cam retaining plate bolts huh Richard

I have a 6.0 lq4 in my truck 2006 2500 hd looking for a engine builder I want 535hp , matching trans to handle engine power ,

I have 60 n LS engine in my 03 SS SILVERADO WOULD LIKE TO BOOST IT UP TO AROUND 450HP I DRIVE THIS TRUCK ALOT, WHAT HEAD & CAM COULD I USE AND STILL PULL MY TRAILER SOME? AND BE ABLE TO DRIVE IN STOP AND GO TRAFFIC!

You have an LQ9 which is basically the iron block, truck version of an LS2. I would use either ported 243 or 706 heads with the larger valves. A TBSS/NNBS intake You will need a throttle body plug adapter but you will want a 4 bolt 85-90mm throttle body, 1 7/8 headers. For a cam I always recommend calling someplace like Comp, tell them your combo, what it’s in, and what you want out of it. I’m guessing but I had a cam custom speced for a similar combo and it was around .618/.624 .239/.242 115LSA +4 degrees. Power comes in low, around 2200 RPM range and carries all the way up to 6500. Didn’t have a lot of lope, didn’t need a big converter, idled around 750. And made damn good power. My set up had a bit higher compression with 243 heads milled .005 and I used FelPro MLS head gaskets which have a compressed thickness of .048 instead of .052 or .054 for GM MLS gaskets. You will definitely want to check pushrod length.

What is the compression ratio on this 500 plus hp 5.3 engine…

This is another exercise in silliness in LS land Why would you do anything like this ever, and spend thousands extra, when you could buy a stock 6.0 from someone for $1000, put a cam in it and it would make a little more hp and ALOT more torque???? Plus have tons more room to grow being able to add decent heads, manifold etc?

This is for a low budget builder not everyone has a grand to spend I think it’s very good info just saying

Thousands lol? Id skip the fast 102 for a $250 tbss only about 15-20 less hp at 1/4 of cost.

Other than that and the heads it’s a $400 cam and spring kit and a $100 trunnion kit..

Where do u get thousands?

would this be possible wit an all aluminum ls4 5.3 out of a 07 impala. I’m putting it in my 87 fiero

Richard that’s a great idea for the budget builder and for a street car or daily driver what more would you want or even for a street & strip car that you can drive to and from the drag strip!!!

Did all of the 6.0 comments read how to make 500 with a 5.3?

those are the same 6.0 guys that say they find them stacked in the salvage yard for $400 all day, everyday. LOL!

Hey Guys. Have a Gen 3 2011 Chevy 5.3L out of my Tahoe that I want to build and put in my 65 GTO project. My question is this Motor has AFM on it and the Summit Pro LS cam says that it is not for AFM/VVT motors. What do I need to do to make this work? Also do you have a complete parts list with part numbers for this build you can share?

Hey Mark, cool project! We love us a vintage Goat build around these parts. Here are two articles that’ll give you some details, and you can always contact the Summit Racing tech line and they’ll walk you through it, no problem.

* How to Delete Variable Valve Timing (VVT) on an LS Engine

* How to Delete or Disable Active Fuel Management (AFM) on GM Engines

do you have blow off valves for sale ? t have a 340 mopar with twin turbonique turbos it makes 600 hp on propane done by ak miller but

are the turbo smart blow off valves much better than blow off valves from 30 yrs ago? my engine has carillo rods and forged pistons

i have a comp cam it idles like a taxi cab 1 am 78 yrs old medical physition still practicing near long beach

Sure, check out hundreds of blow-off valves available at Summit Racing by clicking here.