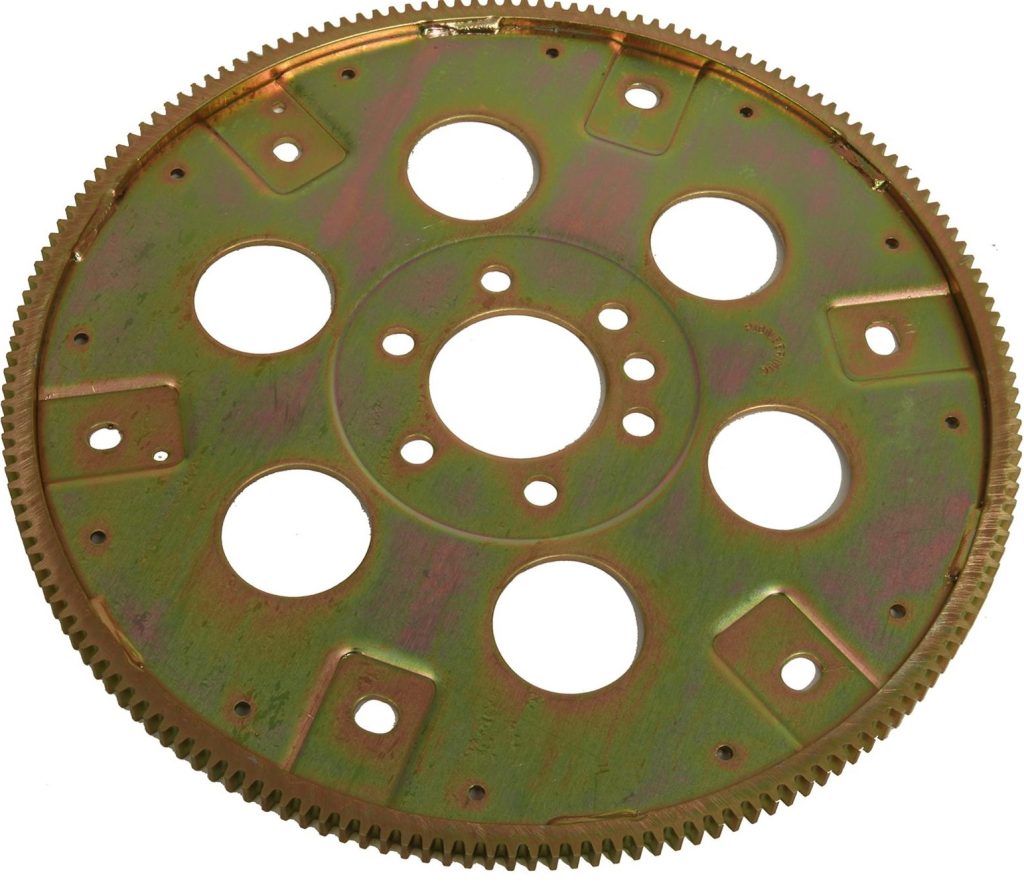

Unless your automatic transmission car has a vintage Clutch-Flite or Clutch-Turbo, there’s a pretty good chance it will be equipped with a flexplate. The reason for a flexplate is to hook the torque converter to the crankshaft; it also provides a ring gear so that a conventional starter can be used to spin the engine over.

Fair enough, but that’s the simple definition.

Ponder this: Believing that everything from the damper centerline to the crank rear main centerline to the input shaft of the transmission is perfectly aligned is a mistake. In a production car environment or even in a high performance or racing application, it’s not always possible to be 100% accurate. Tolerances stack up and the flexplate needs to be, well, flexible in order to make up the differences. Also keep in mind there is fluid moving through the torque converter. The converter tends to float, moving forward and backward as engine speed increases.

A flexplate allows the converter to move—but not bottom out on the transmission, which can cause damage.

Because of these factors that’s why it’s referred to as a “flexplate.”

Basic stuff. But there are a lot of different flexplates out there for a lot of different applications. In fact, SummitRacing.com has hundreds upon hundreds of different flexplates. Some have an SFI spec sticker (which as most know is necessary for any number of different drag race sanctioning body classes). Some do not.

There are two different SFI specs for flexplates: SFI 29.1 and SFI 29.2.

The SFI notes the certification process involves spinning a test fixture (with a flexplate attached) to 12,500+ RPM for an hour. The flexplate is checked for integrity once the test is complete. What the test is looking for in particular is the weld integrity at the ring gear. There are some differences between 29.1 and 29.2, particularly in materials for the flexplates. There are also some differences in the SFI test procedure. Typically, cars running 9.99 seconds (1/4-mile) or quicker require a 29.1 spec flexplate, while the 29.2 spec has been established for “high horsepower cars” (think extra-big power Pro Mods or outlaw street cars).

There are also a couple of different types of construction methods used in manufacturing flexplates. The most common is to weld a machined metal center section to a ring gear. The other format is to carve the entire piece out of billet. Billet configurations clearly offer exacting tolerances and different options when it comes to weight and configuration.

Although billet sounds like the top end ticket, some manufacturers disagree. The folks from ATI Transmission Performance note: “ATI’s flexplate design is derived from a vast array of auto manufacturers, including big names like Lamborghini, Mercedes Benz, Bugatti, as well as 30 years of our own experience. A billet or thicker flexplate does not flex and therefore cannot absorb the “allowable tolerances” and that, in turn, can cause damage.”

Bottom line here, there are two different trains of thought and you can decide.

There’s also quite a difference in price. Typically, a billet flexplate will cost close to $450, depending upon the application. Higher end SFI 29.1 flexplates are often less than half of that.

Why not just use a stock flexplate?

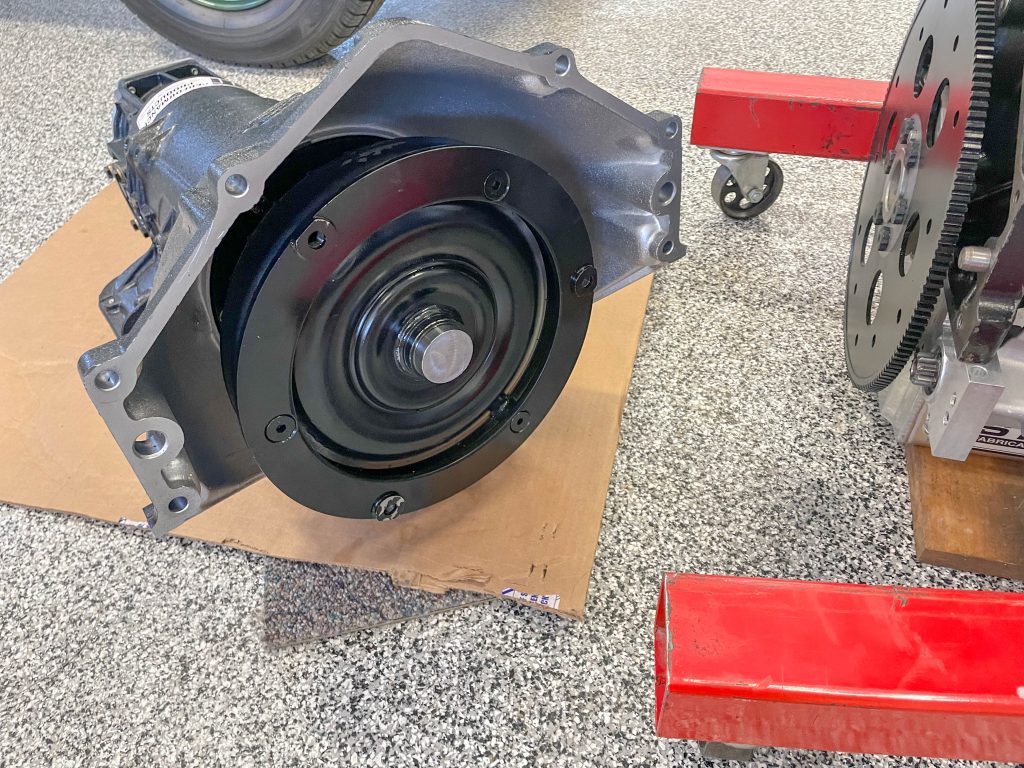

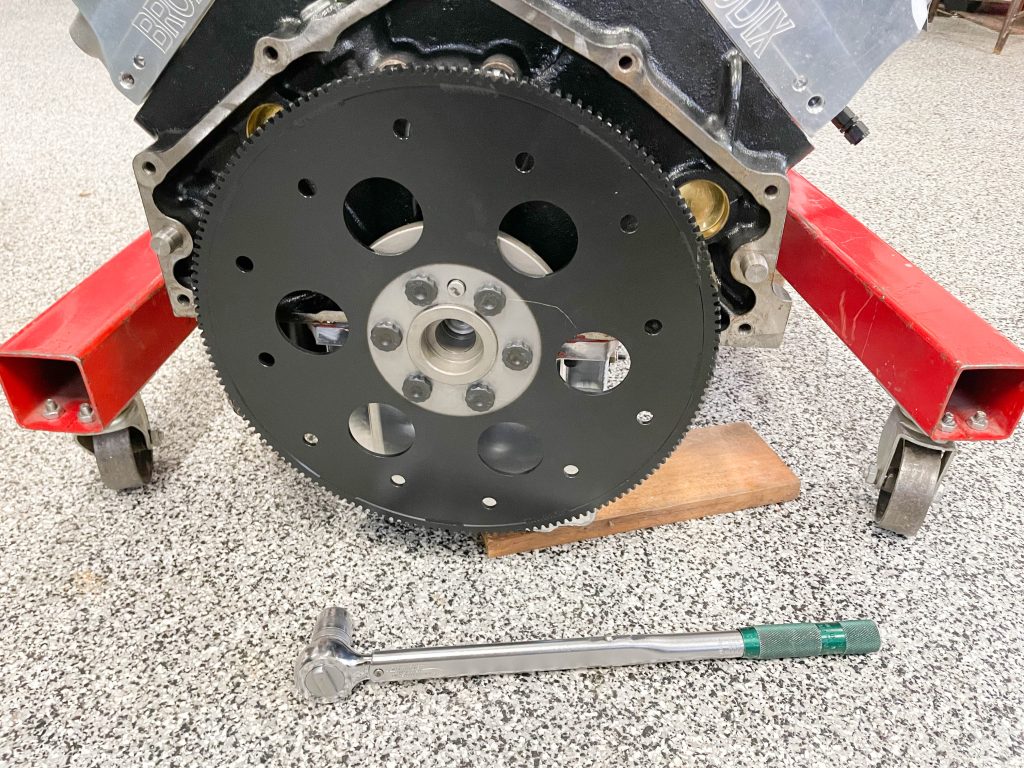

You can. But many of the 29.1 flexplates are precision manufactured using CNC equipment. For example, ATI (manufacturer of the flexplate shown in the many of the accompanying photos) tells us its SFI 29.1 spec flexplates are also double MIG/TIG welded for additional strength (welded on both sides). It manufactures the plates using OEM drawings and once complete, they’re inspected to ensure they exceed the flatness and runout tolerances of the OEM examples. Finally, each is precision balanced on Hines digital equipment with a resolution of 1/10 oz.-in. Other manufactures use similar processes with their SFI spec products.

When it comes to flexplates, you’ll find some are available for internally balanced engines while others are engineered for use with externally balanced engines. This means there is a special (additional) balance weight added to the flexplate. A good example here is a stock style 427 cubic inch big block Chevy. It is designed as an internally balanced engine. On the other hand, a stock 454 cubic inch big block Chevy is externally balanced. This means the harmonic damper/balancer and the flexplate or flywheel contribute to the engine reciprocating assembly balance. You can’t mix and match components. Pick the right balance (internal or external) for your engine application.

There are also several flexplates available that are much heavier than stock. The idea behind them is to add inertia on the launch—similar to a heavyweight flywheel. J.W. Performance Transmissions is one of the companies that offers heavyweight as well as lightweight flexplates. Certain applications can benefit from the heavyweight flexplate, but if you need to spool up a turbo or need quick response in a street car, a conventional weight flexplate is a better bet.

Summit Racing also carries plenty of swap flexplates.

Never heard of a swap flexplate? If you’re swapping engines and different automatic transmissions, there’s a good chance you’ll encounter the need for a swap flexplate. Case-in-point, a Chevy LS swap with an early TH400 (or even a Powerglide). There are several different examples for this exact swap at SummitRacing.com, but there are even more. Need to swap a TH400 behind a Cummins diesel? There’s swap flexplate for that too.

As you can see, there’s more to flexplates than meets the eye. There are more shapes, sizes and applications than you may have surmised. In the accompanying photos we’ll look at a few examples and we’ll also provide some insight into installation. Check it out:

Nice article. Thank you