Q. I am choosing a torque converter for my 1970 Nova with a 430 hp 383 stroker and a 4L60 transmission. I see lockup and non-lockup options. My understanding is that a lockup converter is intended for fuel economy, so would a non-lockup version be better for performance?

A. Lockup torque converters became popular in the 1980s to meet federal fuel economy standards, but they are also beneficial in performance applications. When a torque converter clutch is engaged, it creates a near direct-drive effect and slippage becomes virtually non-existent, regardless of rated stall speed.

A non-lockup converter can build excessive heat during normal cruising, especially in overdrive when engine rpm drops below converter stall speed. Installing a non-lockup converter in your 4L60 would also require a conversion valve kit to be installed into the front pump of the transmission.

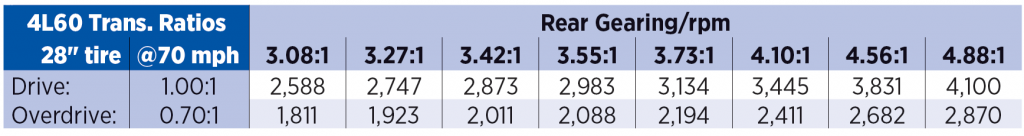

Above is a chart showing examples of a vehicle cruising at 70 mph with a 28″ tall tire, a 4L60 (700R4, 4L60E, and 4L65E are the same) transmission, and popular rear end ratios. Notice the rpm difference between drive and overdrive, even with lower (numerically greater) gear ratios. Use an online calculator to find the numbers for your specific combination.

Choosing converter stall speed is largely based on camshaft operating range, and a lockup converter allows you to lean toward a higher stall speed for a better launch. Be cautious with this, though; relying on a lockup converter to compensate for a stall speed that’s way too loose will put an excessive load on the clutch during engagement, significantly shortening its life.

So is this chart for 3rd gear and 4th gear overdrive? What is the rpm drop with lock up converter and non lock up converter? What is this article about anyway?

Typically you will see a 200-300 RPM drop when the converter locks. It feels like 5th gear though no gear change has occurred.