Right up front, the question is: What the heck is a Cleco?

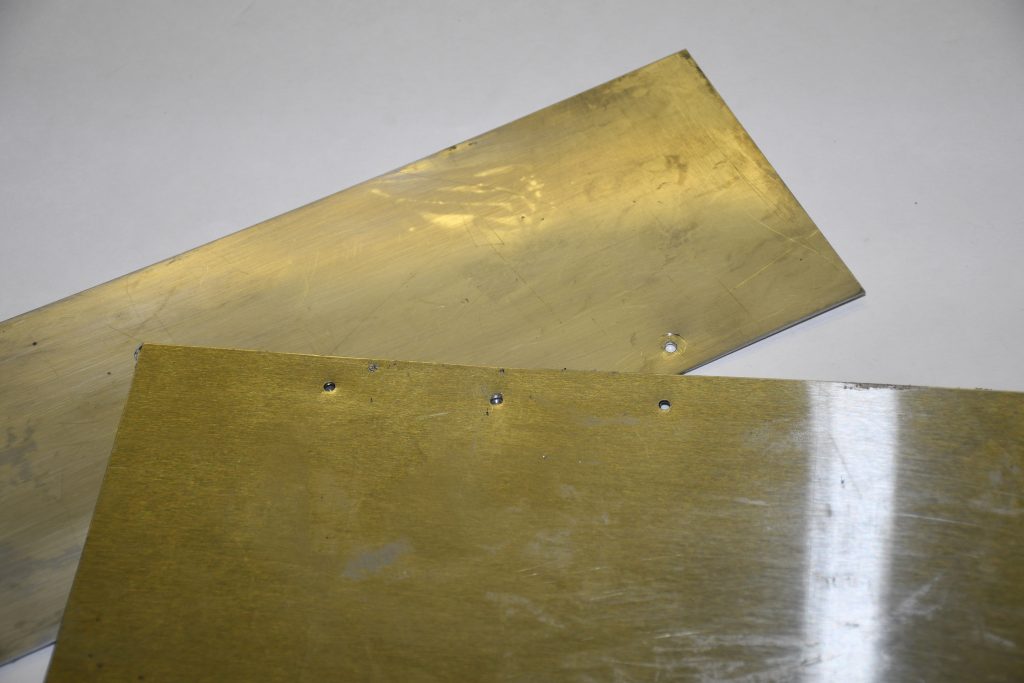

Clecos are reusable fasteners engineered to securely clamp panels and sheetmetal together before they are permanently assembled. They’re used extensively in the aircraft biz, but they also see considerable use in the automotive aftermarket.

Where & How Are Cleco Pins Used?

In the racing world, fabricators regularly use Clecos to temporarily fasten aluminum panels, body sheet metal, Lexan windows, fiberglass and carbon-fiber components. They can also be used to grip brackets and other parts before they’re welded in place. In addition, the way Clecos are designed, they function as blind fasteners. That means you use them in tough spots, even those where you can’t access the back side.

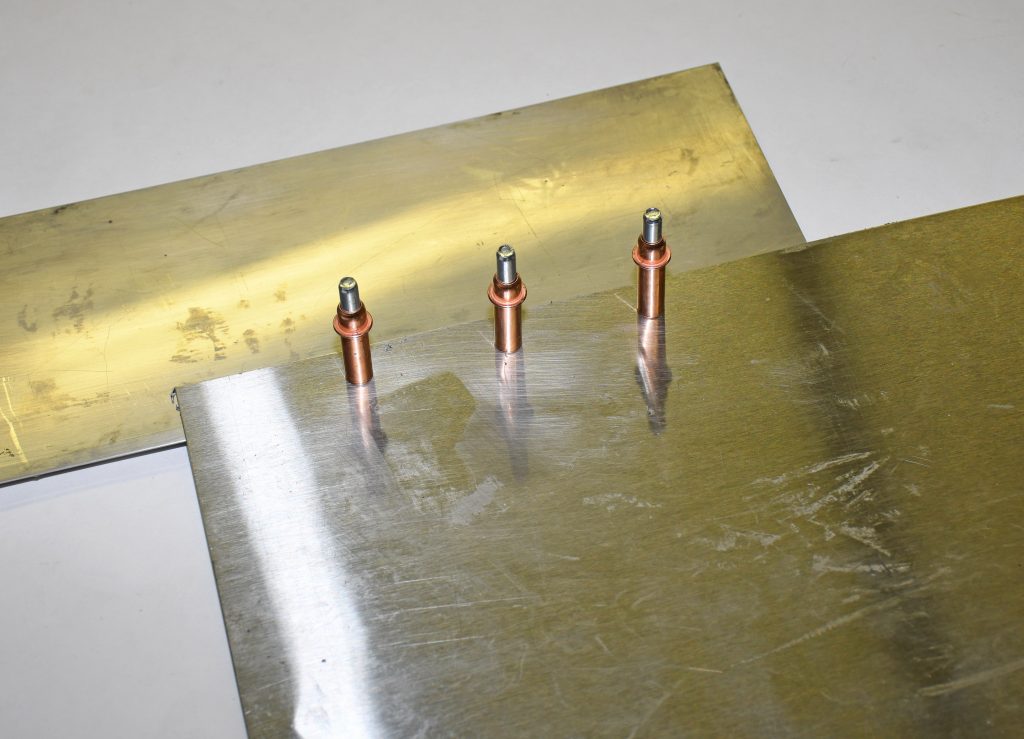

There are all sorts of Clecos available, and they’re color coded with regard to the hole size. Check out the chart below:

Cleco Sizing & Color Chart

| Hole Size | Color |

|---|---|

| 3/32 in. (#40) | Zinc |

| 1/8 in. (#30) | Copper |

| 5/32 in. (#20) | Black |

| 3/16 in. (#11) | Brass |

Summit Racing offers a Cleco kit with the most common Clecos included (1/8 inch and 3/16 inch). The kit consists of ten 1/8 inch Clecos, fifteen 3/16 inch Clecos, as well as the special pliers required to install and remove them. Additionally, Summit Racing offers extra Cleco pins in multiple sizes and quantities too.

How to Install Cleco Pins

Fair enough, but are they difficult to use? Hardly. Once the holes are laid out and drilled in the respective pieces, you position and align the parts. Then install the Cleco pin in the special pliers and squeeze its handles. This extends the pin and actually makes it smaller in diameter. Insert the pin through the hole in the part and release the pliers. Done!

Essentially, the Cleco pin has a grip range of approximately 1/4 inch. As the pliers are released, the pin draws the panels together, simultaneously maintaining alignment. Because the fasteners are temporary, it allows you to move and shift the part in question before you permanently affix it in place.

The Cleco fasteners also allow you to massage a panel in order to provide a revised or flush fit. Basically, you can assemble and reassemble the panels as many times are necessary to get the fit and shape you need for your project. When you’re ready for final assembly, the Clecos are easily removed by way of the pliers and replaced (sometimes one by one) with rivets, bolts, or screws to permanently join the pieces. It’s also possible to plug weld the holes in the panel.

As you can well imagine, these are extremely useful little fasteners. Once you’ve used them, you’ll wonder how you ever managed to work without them. Basically, they’re like having a spare set of hands. For a closer look, check out these photos:

Comments