I’m new to the old car hobby (cars of any kind really) and I’m trying to learn all I can. One thing I’ve noticed is that some rear wheel drive cars will spin just the right rear tire while others will spin both rear tires. A friend told that’s because of a limited slip in the rear end. How does that work?

B.K.

This is a great question that will require an explanation that is somewhat involved due to multiple variables.

In a typical front-engine, rear wheel drive vehicle with a solid rear axle, improving traction is about managing torque of the engine. Let’s use a 1969 Camaro with a big block and an automatic as our example.

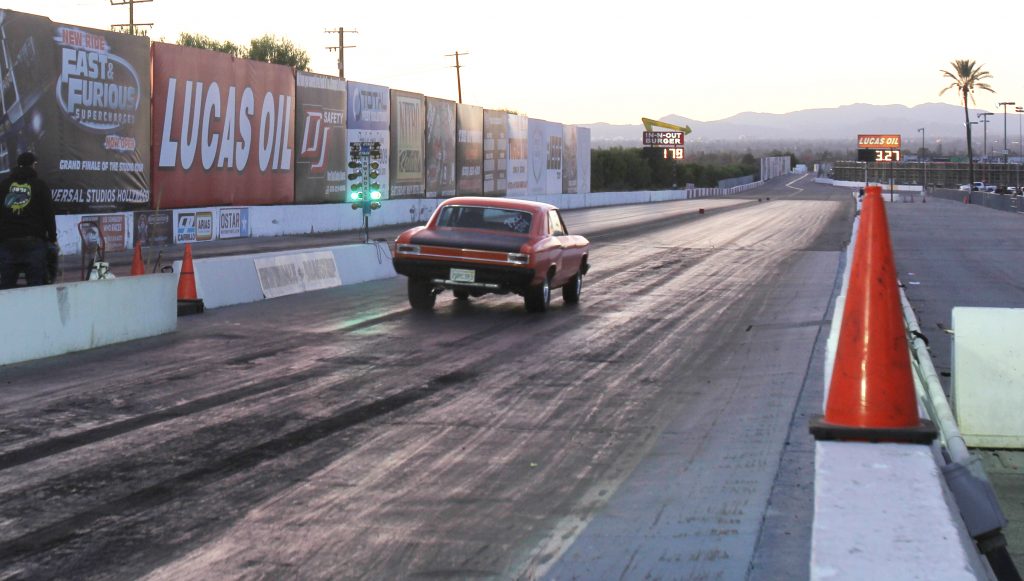

Let’s say we take our Camaro to the drag strip and launch the car hard. As the driver nails the throttle, engine torque is multiplied by the converter, the First gear ratio in the transmission, and the rear axle ratio. Let’s estimate engine torque at stall speed at 400 lb.-ft. With a 1.4:1 torque multiplication in the converter, a 2.48:1 TH400 First gear ratio and a rear axle ratio of 3.50:1, simple math will give us the torque created at the rear tires: 400 x 1.4 x 2.48 x 3.5 = 4,860.8 lb.-ft.

This massive amount of torque is split between the two rear axles and the rear tires.

If we are looking forward from the rear of the car as it launches, you will see the left front corner of the body lift higher than the right front corner. You’ll also notice (in most cases) that the right rear portion of the body will tend to dip or squat. This is engine torque trying to twist the body and frame of the car. Still looking at the car from the rear, the rear axle housing will twist in the opposite direction, attempting to lift the right rear (passenger side) tire off the ground while planting the left rear.

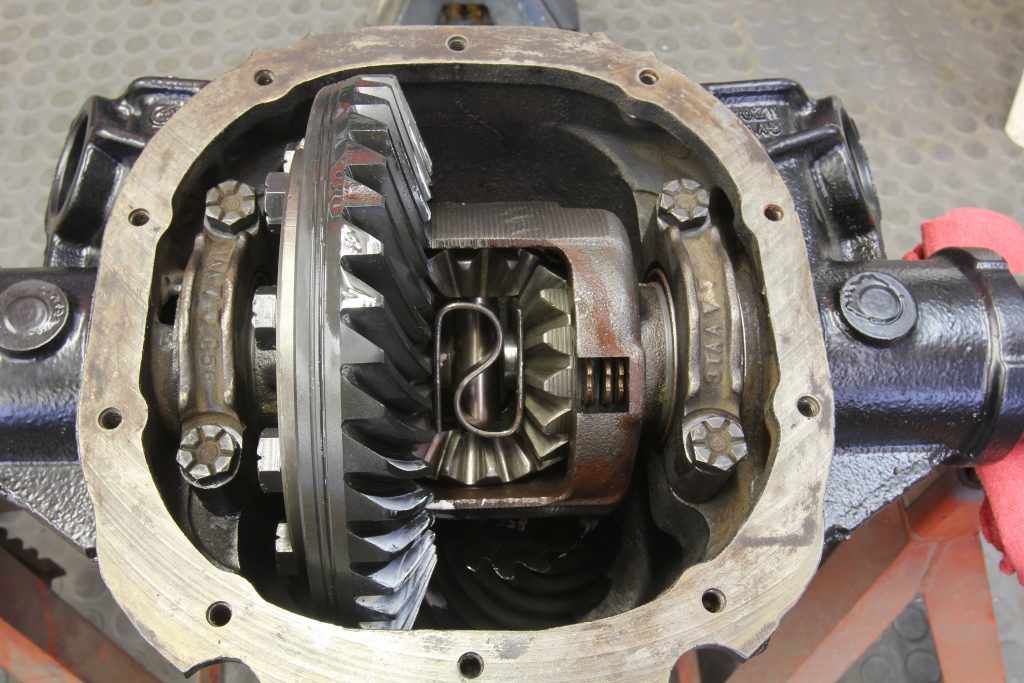

This occurs because the pinion gear is attempting to climb the ring gear under acceleration. This inputs a twist into the housing. Because the pinion is turning counterclockwise (as viewed from the rear), this twisting motion of the housing will unload the right (passenger side) rear tire, reducing traction and allowing the right rear tire to spin. This twisting motion will always occur whether the car is equipped with a limited slip differential or not. But the right rear tire spin is especially noticeable if the rear axle is equipped with what is called an open or non-limited slip differential.

What is a Spool or Welded Differential?

We should insert here that dedicated drag cars eliminate this open differential and use what is called a spool that directly connects both rear axle shafts together so they turn equally. A spool should not be used in a street-driven vehicle because when turning a corner, the inner tire will travel a shorter distance than the outer tire. If you’ve ever tried to push a drag car equipped with a spool, then you know how difficult it is to push the car if the front wheels are turned sharply. To accommodate this situation for street cars, a differential is used to allow the two tires to freely turn at different rates when negotiating a corner.

If you attempt to use a spool (or welded spider gears in the differential) this will impart a twist into one axle or the other with every corner which will eventually break one or both of the rear axles. The solution for a street car is to use a limited slip differential that will attempt to minimize the slip in straight ahead acceleration but still allow differential operation when negotiating a corner.

Compensating for Wheel Lift & Frame/Chassis Twist

We will go into some detail on limited slips as there are many different versions, but from the above description of what is occurring in the rear suspension, you can see that any limited slip differential is somewhat of a band-aid or minor improvement because the right rear tire is still going to lift when torque is applied under acceleration. There are ways to counter-act that natural movement of the rear axle housing.

This can be accomplished in several different ways. For example, on coil spring cars like a Chevelle or Fox body Mustang, you could place an air bag in the right rear spring and “preload” the suspension with approximately 10-15 psi of air in the bag. This will counteract the torque and actually load both rear tires equally. Or, a large anti-roll bar attached to the frame and rear axle can be used to stabilize this twisting motion of the body and plant both rear tires equally. Finally, traction bars, ladder bars, or four-link rear suspensions can be simply preloaded to establish an equal load on both rear tires.

Understanding the Types of Limited Slip Differentials

Getting back to limited slips, the most common version employs a series of clutches that are loaded to minimize slippage in straight ahead acceleration. These clutches can be adjusted to improve traction to the right rear tire under hard acceleration. Other variations of a limited slip would be cones instead of clutches and Eaton makes a gear style called the Truetrac that performs very well and is less susceptible to wear over time. We’ve used it with great success in an autocross Chevelle.

Getting Started With Performance…

Of course, once you address all of this and improve both the suspension and perhaps add a limited slip and bigger tires, you’ll improve traction and quickly realize that now you need double-adjustable shocks, better tires, wider and lighter wheels to improve acceleration, and about a hundred other goodies necessary to make your car quicker.

This is a fun process to gradually improve traction that will also produce quicker elapsed times in straight line acceleration. Enjoy your quest!

You may have forgotten, but there is another device called a “locker” or locking differential. Moving ahead both wheels lock together like a spool. The axle stress of rounding a slow, sharp curve “unlocks” the differential, to an “open differential” mode, and wheel speed isn’t an issue. They hold a lot more power, especially over time, than a “posi-traction” style, clutches and cones alike. Like Ford’s famous “Detroit Locker”. Having used a “spool” on the street…I can’t see the problem…but a locker is a nice compromise.

[…] I’m new to the old car hobby (cars of any kind really) and I’m trying to learn all I can. One thing I’ve noticed is that some rear wheel drive […] Read full article at http://www.onallcylinders.com […]

Open Differential (one wheel peel, peg leg)

(The most common factory installed type)

Does not limit the slip of the low traction tire.

Allows differentiation around corners.

Limited Slip (Posi, Trac Lock, Sure Grip, Saf-T-Track,Gov-Lock,

Eaton Posi, Detroit Tru Track, and Auburn)

(The most common optional factory installed differential type)

Uses clutches or binding of gears to limit the slip of the low traction tire.

Allows differentiation around corners.

Locker (Detroit Locker, Lock Right, No Slip Traction System, Spartan Locker)

(very rare from the factory)

Uses ratcheting gears to lock both axles together.

Allows differentiation around corners.

Spool and Mini Spool (Never factory installed)

Positively locks axles together

Does NOT allow differentiation around corners.