Recently we shared a number of tips on things you can do while you’re on Covid Lockdown. Some of those tips included the use of hose caps over sheet metal screws, setting up a bump switch for the starter, using studs instead of bolts for hood hinges, using special B&B transmission crossmember bolts and so on.

Those tips actually originated on racecars the writer had built over the decades. With a racecar, every time you complicate something, it adds something that can break or skip a beat.

Complexity also adds up to wasted time in the pits. Even though those tips were based on things done years ago on race cars to make them easier to work on, you can still use them on a street-strip machine. As you can well imagine saving time between rounds or when servicing a car at home by making things easy to work on is a win-win. With that in mind, here are a dozen more “Simple is Good” tips.

1. Simple is Good

The “most-fun” cars we’ve ever had were simple beasts.

They had no radio, no heater, no power steering, power brakes or other creature comfort stuff. All of those things cluttered up the car, got in the way during servicing and just added complexity. Consider building a simple car — you might really dig it. Besides, if something isn’t there, it can’t break down or leak or fall off!

2. Quick Clamps

You don’t see racers flushing cooling systems as much today as you did in the past, but way back when, hose clamps with built in “T’s” on the tightening screw were very common. It made removal and replacement of the rad hoses easy. Today, you can still buy hose clamps with thumb screws or combination hex and slotted heads. And yes, they still allow for easy and quick R&R of hoses.

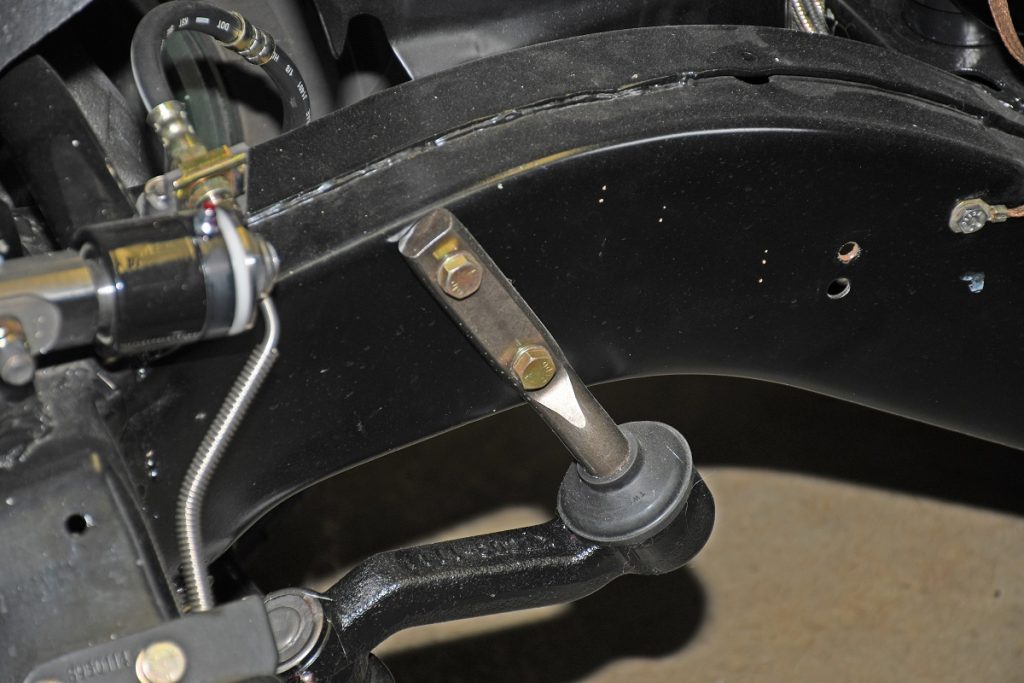

3. Backward Bolts

If you have a first gen Camaro or similar Nova (or other similar car for that matter), you probably know that the idler arm bolts are long and the excess threads can get it the way when you’re attempting to remove and re-install headers. The fix is simple: Just turn the bolts in. They’re still easy enough to get at, but the headers don’t hang up on the excess threads.

4. Quick Disconnect

When you have an electrical component that might require replacement on race car, it was (and still is) a good idea to setup the connections with a quick release plug. Case-in-point is the distributor-to-MSD trigger wiring in this photo. We typically wire them with a Weatherpack connector. That makes installation and removal easy, especially with the buzz box and coil inside the car. The same can apply to line lock solenoids, fuel pumps, and other electricals.

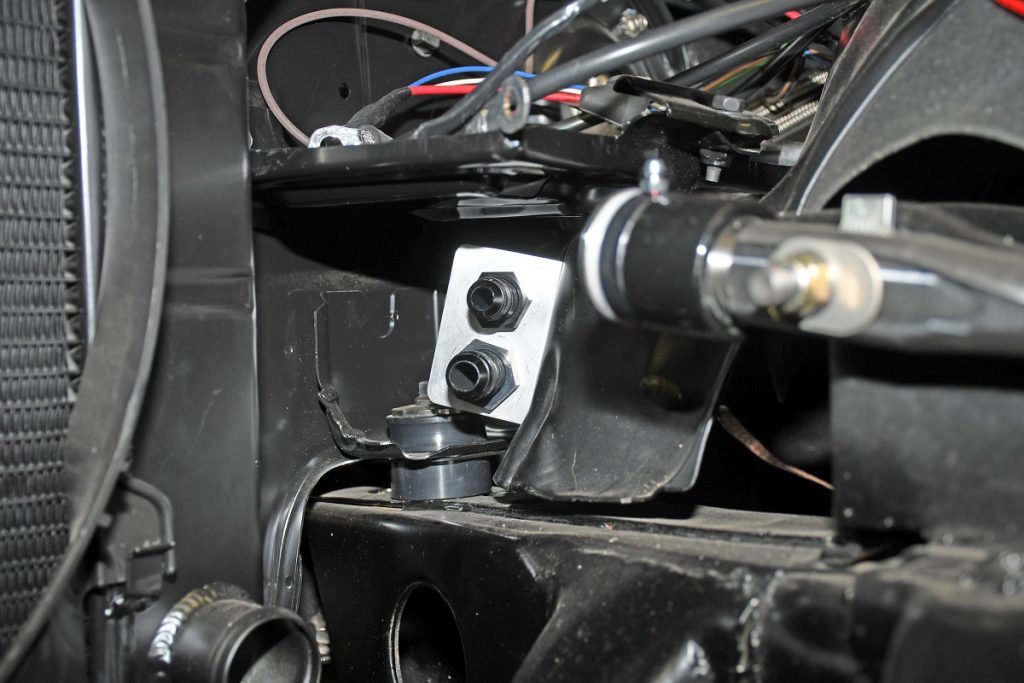

5. Bulkhead Plates

When it comes to the fuel system on a car, we prefer to route the pressure and return lines to a fabricated plate (bolted to the car) fitted with bulkhead fittings. From that point, it’s easy to plumb a short pressure and return line on the engine (it can be hooked to an engine mounted regulator or in our most recent case, a by-pass valve). This allows you to easily pull the engine by simply removing two fuel lines. It’s a clean setup and easy to work with.

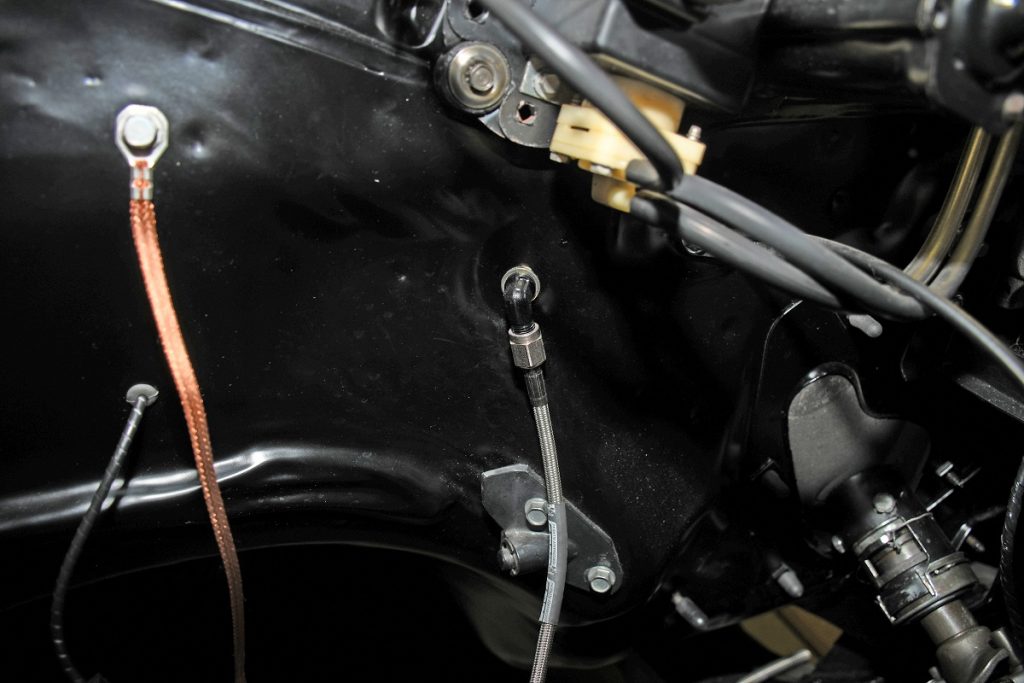

6. Oil Down

Another place where AN bulkhead fittings prove very effective are oil pressure gauge lines. We usually add a bulkhead fitting on the firewall car. On the inside, a braided hose routes from the gauge to the bulkhead fitting. And on the engine compartment side, it’s simple to plumb a braided line from the bulkhead to the engine. This setup makes disassembly (and reassembly) simple.

7. Strain Relief

In some cases, you might not want to use a quick connector for a wire (or harness) that runs through a firewall. Sure you can use a grommet, but there are some other better options. We like to use a “Heyco” strain relief bushing. Essentially these are a threaded tube with an internal iris. They have a connection nut on each side. Once you tighten the nuts, the iris closes and the wire harness (or wire) is tight and seals at the firewall.

8. Welding Plugs

Speaking of quick releases: If you have a car with a trunk-mount battery (or two), consider routing the battery power cable through the rocker panel and through the passenger side kick panel. Where it reaches the firewall, you can wire in a welder electrical plug. Then it’s a matter of having a short piece of cable from the welder plug to the starter. Jerry Bickel Race Cars made up the kit shown in the photo.

9. Drain-O

This is another oldie but a goodie. Block drains can be a royal pain — especially if the bolt heads become rounded. A better solution (and one racers have incorporated for eons) is to use a pair of radiator petcocks instead. This makes draining the block easy and it’s a simple swap.

10. Check Valve Disconnects

Jerry Bickel offers a slick disconnect for oil pressure lines. It makes disconnecting the oil pressure line a snap. Summit Racing offers a similar lineup of disconnects manufactured by Earl’s Performance, Allstar Performance and others. Internally, there’s a check valve in the fitting that keeps the line from leaking oil when disconnected. Cool idea.

11. Number One with a Bullet

Bullet nose carb studs have been available for a long time, but some folks still don’t use them. The reason you should consider them is they make it easier (especially if you’re in a hurry) to start the nuts. All sorts of bullet nose studs are available in a wide range of lengths.

12. Zippity Do Dah

Nylon zip ties obviously have countless uses on a car. They work great. Unfortunately, they can be just as sharp as a knife once the excess “tail” has been removed. To solve the problem, simply touch the cut off end with a hot soldering iron. It blunts the end and you won’t have to rush to the medicine cabinet when you least expect it.

…

Bonus! Jiffy Marker

This is another oldie, but it works. We typically use a felt tip marker to write down the jet numbers used in the carb right on the carb. That way, you know exactly what direction to go when tuning. We also mark the distributor cap with a big “1” on the number one post. Both ideas save time in the pits and if you have to make a change (on jetting), it’s easy to remove the jiffy marker with a dab of brake cleaner.

[…] Recently we shared a number of tips on things you can do while you’re on Covid Lockdown. Some of those tips included the use of hose caps over sheet metal […] Read full article at http://www.onallcylinders.com […]

I use V band clamps where it makes sense on my exhaust so I can remove sections, not the whole thing when needed

This is an amazing unit, thanks for this! | Website

Lick me

I love the information that you’ve posted! Cyber Security

Jam the spam up your bhole

I’ll share this site to my co workmates, thanks for the updates! | lake forest slab leak detection

Coworkers! Haha robot scum

These are nice tips to prevent overpriced maintenance. Thank you! John

I’ll definitely need to remember this by now. You’re awesome!

https://www.concretecontractorscincinnati.com

You’re a turd

Thanks a lot! I will be purchasing a new car and been searching the essential skills to learn for it.

http://www.svgbeavercreek.com

Outstanding! I think this has been thought through much. 🙂

our site

Glad to see this post. https://www.centralalbertatowing.ca/

Keep it simple is exactly right. I don’t waste a nickel on paint, chrome, other shiny crap. Good brakes, suspension, steering. The rest is in horsepower.