When a camshaft is “degreed” it means the camshaft position in the engine has been synchronized with the crankshaft position.

Degreeing the cam is the only real way to determine if the rise and fall of the pistons correctly matches the opening and closing of the valves. Several degrees of misalignment can have a profound effect on engine operation and performance.

In a perfect world you’d only need to line up the timing marks on the timing gears (sprockets) and you’d be good to go. But the truth is, there’s a good chance dimensional stack ups will catch up to you. Things like tolerances in the camshaft, crankshaft, timing chain, and sprockets can add up. As a result, checking the relation of the camshaft to the crank (or “degreeing the cam”) is the only option.

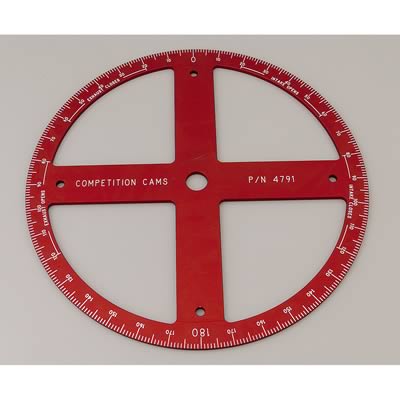

To degree the cam, you’ll need a degree wheel. Prices range from roughly $15 up to $220+. Less-costly examples aren’t as large in diameter as the more expensive ones, some of which are designed so that you can access the timing set for bushing changes without removing the wheel. Because these large degree wheels have an open design, they have to be built rather beefy. As a result, they’re typically a full ¼-inch thick.

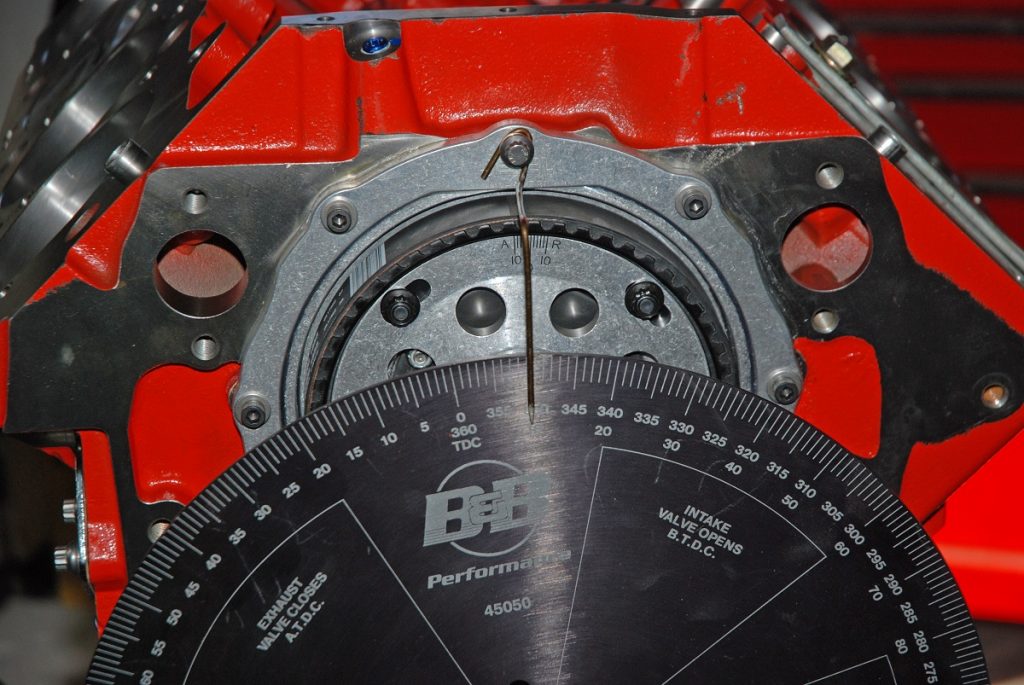

When it comes to overall diameter of the degree wheel, you’ll find the least costly ones typically measure about 11 inches. As the wheel size increases, the cost goes up. But there’s a pretty big advantage to a larger wheel — they’re easier to read and as a result, can be more accurate than smaller ones. If you check out the accompanying photos, I’ve placed an 11-inch diameter Moroso degree wheel alongside a 14-inch diameter B&B Performance (Stef’s) degree wheel. You can see that the difference on the scale is considerable.

Some degree wheels include center adapters to fit the cranks of various engines. Some do not and you’ll have to order them separately. Further to this, some wheels are designed to work in conjunction with crankshaft turning sockets too (case-in-point is the big professional COMP Cams degree wheel shown in the accompanying photos).

In many cases, you’ll have to buy or fabricate a timing pointer to work with the degree wheel. Powerhouse Products makes an inexpensive one. If you want, you can build something similar from a metal coat hanger.

In the end you’ll find the choices are many when it comes to degree wheels. It boils down to your budget. Since they’re simple devices, they all work well. Here’s a closer look at some other degree wheel options.

I appreciate seeing articles like this, keeps me sane and in touch. Just a few weeks ago there was a debate going on in an online chat where several participants were spewing that degreeing a cam wasn’t necessary these days. I wanted to say something but so many joined in on the banter I figured I’d just let it be and allow these mental midgets have their moment in the sun. Thanks again.

The first decision to make, and which was not mentioned, is whether the engine is in the car or is on the stand. Many large ones will not work if engine is in the car. Not everyone has the luxury of pulling the engine when changing a cam.

Yes, the article is cool. Grateful to the author. I will ask only one thing to give more information.

I know a cool site, real copywriting masters work on it. They will write an essay, an article, or a report on any topic for a fee, but it’s worth it. Service and deadlines are just top. Go to my profile for a review.

Now that’s some different level of manufacturing. In terms of quality, rest assure it is good.

Good day! Very interesting.

MORE INFOABOUT CRANK SOCKETS & WHEEL ATTACHING PARTS WOULD HELP. pARTS NEEDED TO USE THE WHEELS

Thank you