Brake proportioning valves are the parts of a vehicle’s brake system that limit the amount of pressure reaching the rear brakes, which helps to prevent rear wheel lock-up, allowing you to stop your vehicle more safely and efficiently.

Whether your vehicle has rear disc brakes or drum brakes, the rear brakes require less pressure than the front brakes, which is why the brake proportioning valves exist, and why they’re so important.

There are three common styles of brake proportioning valves.

1. Fixed Proportioning Valves

This type of valve is not adjustable. Fixed proportioning valves are typically used in stock applications, or in applications that fit specifically to a particular brake setup.

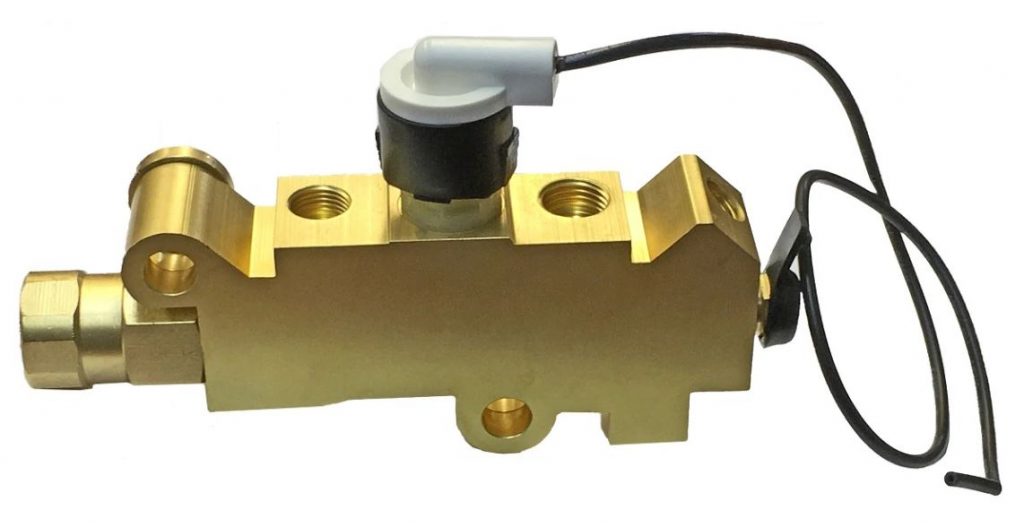

2. Adjustable Proportioning Valves

This type of valve—as the name suggests—is adjustable. Adjustable proportioning valves are typically used in an aftermarket brake system where the vehicle owner might need to adjust the braking pressure going to the rear brakes.

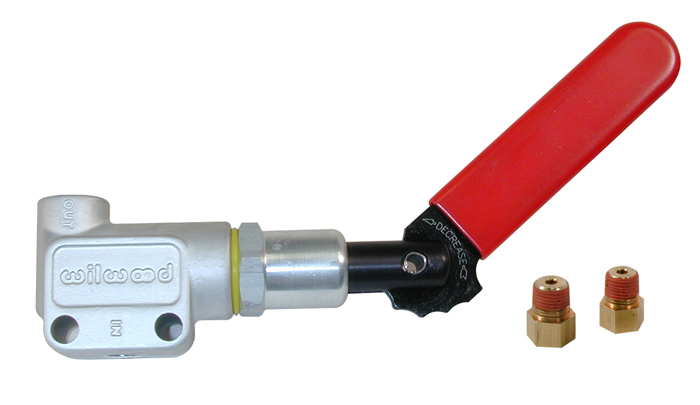

3. Lever Proportioning Valves

Lever proportioning valves are also adjustable, but use a lever rather than a turn knob to adjust the rear brakes. These types of valves are typically ran in line with the rear brake lines.

…

Brake proportioning valves work exclusively with rear brakes. They do no proportioning on front brakes. Most proportioning valves sold today also include a brake light switch.

…

Summit Racing tech adviser Mark Lake contributed to this report.

You may want to rethink and clarify your advice that: “Brake proportioning valves work exclusively with rear brakes. They do no proportioning on front brakes”.

The below advice from Strange Engineering pertains to proportioning valves in most drag race applications:

Brake pressure should always be checked with a brake pressure gauge before use. In disc brake applications used for drag racing only, front brake pressure should be 550 to 650 lbs and rear brake pressure 1,000 to 1,100 lbs. These pressures should be achieved with a lot of effort since they are at “lock-up” of the tires and the actual normal stopping pressures will be lower.

When calipers or master cylinders are changed in an OEM system, the stock proportioning valve should be removed in favor of an adjustable proportioning valve. In most drag racing applications, it should be plumbed between the master cylinder and the front calipers to limit pressure. For street applications, or a system using disc front / drum rear, the proportioning valve

would be plumbed between the master cylinder and the rear brakes. In either application, adjustments should be made to the valve in order to achieve the same braking threshold for front and rear brakes.

Lol I brought one so I could have more rear brake!

Install it on the front bakes instead.

On a fixed portioning valve u have large front port 2 in back which line go where?

John, please give our tech partners at Summit Racing a call (1-800-230-3030), and they’ll be able to help you out.

The large port is the rear port and goes to the rear brake line. The two small ports in front go to each front wheel.

I have a 75 Corvette piston caliper rear a Heits super ride front single piston. How would you adjust for braking street.

I have a 75 Corvette 4 piston caliper rear & a Heits super ride single piston front. How would you adjust for best street braking.

I have a 37 chevy coupe with a frame mounted master cylinder (don’t know the source). my mechanic tells me that he cannot adjust the valve to make the front brakes the dominant. Do you have and suggestions to help me, please and thank you

[…] springs. And of course, it got cop brakes that featured semi-metallic front brake pads and a unique proportioning valve to ensure proper brake […]

Brake proportioning valve is discontinued for my vehicle. I’m trying to figure out what to replace it with. It’s a fixed valve for a 96 chevy p30. I have turned it into a food truck and there is a lot of weight in the back. I’m replacing the entire brake system. Any Information would be appreciated. This article really didn’t get into specifics. Could I run an adjustable valve

Did the dealer give you a PN? If so, GOOGLE it and you may find the correct one NOS.

There are also rebuild kits for some valves.

If the truck is heavier than the rating it was assembled with, you might consider a height/load sensing PPV.

I have disc brake in front-shoes in rear.

Just added power booster and need more front disc stopping.

How can I get more power to front?

Same set up as first picture without connector line from front to plug on side.

Is it possible?

can not get left front brake on my 89 lebaron to bleed new pads caliper and rotor full of brake fluid Ideas

I have a fixed propotioning valve on a 1986 regal switching to vaccum system used a vaccum booster & mater cylinder for disc-drum setup the front brake calipers and hoses are new and get real hot driving around town also the brake ligth on the dash wont go out whats going on????