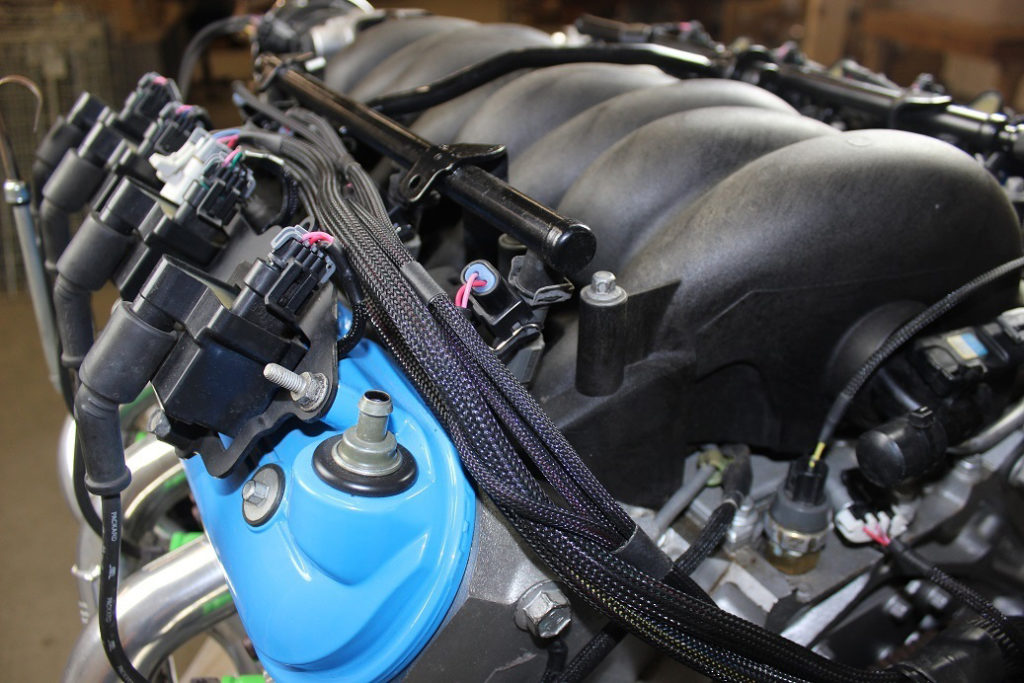

(Image/Wiring Specialties)

OK, gearhead community, we get it.

You want to swap GM LS-series motors in everything—muscle cars, hot rods, imports, trucks, Jeeps, coffee makers, pinball machines, CD players, pipe organs, houseplants, etc.

Problem is, after you pluck your LS from the junkyard, there’s a good chance its wiring harness has been hacked to bits.

And even if it ‘looks’ OK on the outside, an entire colony of electrical gremlins could be living under the plastic loom and convoluted tubing.

Junkyard Hunting for an LS? Read Part 1 and Part 2 of our LS Spotter’s Guides.

We’ve also got a comprehensive set of stories on the GM LS. Start here with LS Engines 101: An Introductory Overview of the Gen III/IV LS Engine Family.

Wiring Specialties has a series of Pro Series Wiring Harnesses that let you toss that questionable junkyard LS electrical harness.

The Pro Series Wiring Harnesses for GM LS use OEM connectors and seals, and is wrapped in a high-temp nylon-braided loom. (Wiring runs near exhaust components get an extra fiberglass sleeve for even more heat protection.)

All harnesses are developed in-house on real engines to make sure they fit and function as designed. Wiring Specialties follows OEM wire color coding, and uses hydraulic crimping machines that make wire-to-terminal connections with over 2000 lbs. of force—just like GM does.

And all harnesses undergo a wire-to-wire electronic test after assembly to ensure no wire pinout mistakes were made.

Wiring Speicalties makes swap harnesses for the following motors/applications:

- 1999-2018 4.8/5.3/6.0L with Vortec truck intake/accessory drive, 4L80E or T-56 transmission

- 1998-2002 5.7L LS1 with Camaro/Firebird intake/accessory drive, 4L60E/4L80E or T-56 transmission

- 2005-06 6.0L LS2 with GTO intake/accessory drive and T-56 Magnum transmission

Have a 87 gm dually with a 454 7.4L where can i find a whole kit to convert into a fuill injection system instead of carburetor and injectors ontop?

I have a 2008 Chevy Colorado that has a 2010 a 5.3L LS1 V8 engine swap. Looking for a plug and play harness that also allows me to have the guages work.