(Image/Holley)

Spin back the clock about 45 years or so.

If you had an engine combination that could handle it, what you really needed was a tunnel ram with a couple of Holley 660 center squirters perched on top. If you burned corners, a cross ram with a couple of 650’s was the ticket.

Over time, technology changed. The old center squirters have fallen out of favor. And today, with multiple carb applications, a couple of well-sorted double pumpers will definitely get the job done.

Of course, Holley’s 4150 double pumper carburetors have been available for what seems like forever. Chevy’s 1969 ZL1 and second-design L88 were the first production cars to be factory fitted with them. Hundreds of thousands of other double pumpers have been sold over the counter at speed shops worldwide.

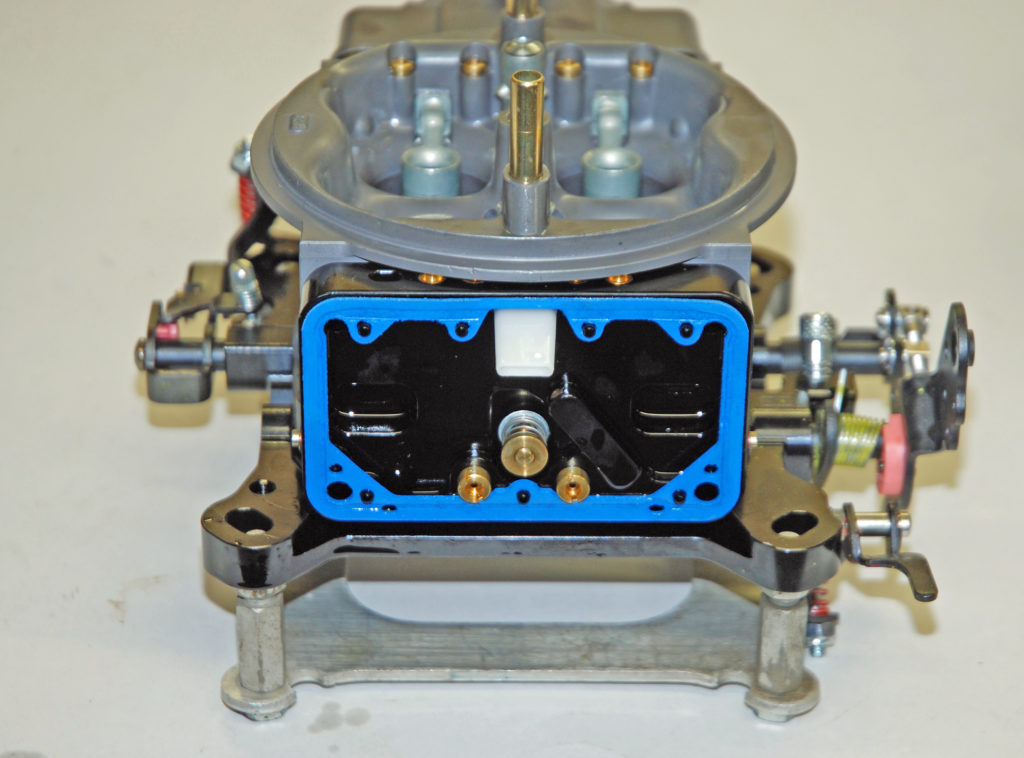

Through the years, Holley’s 4150 series carbs have been poked and prodded with many upgrades. But recently, Holley took the 4150 lineup and pretty much rebuilt it from scratch, creating the Holley Aluminum Ultra XP 4150 series double pumpers which offer unprecedented adjustment and tuning capabilities, and ease of maintenance.

They also made a multitude of changes that make the new XP series perfect for a modern tunnel ram application (such as the LS3 setup shown in the accompanying photos).

What Makes Holley Ultra XP 4150 Carbs Different?

What makes these redesigned Holley 4150’s tick?

Everyone familiar with long-standing 4150 design will notice the radical differences immediately. The new Ultra XP 4150 isn’t the same-old, same-old with a few new trinkets.

Holley now manufactures most of the carburetor in aluminum instead of die-cast zinc.

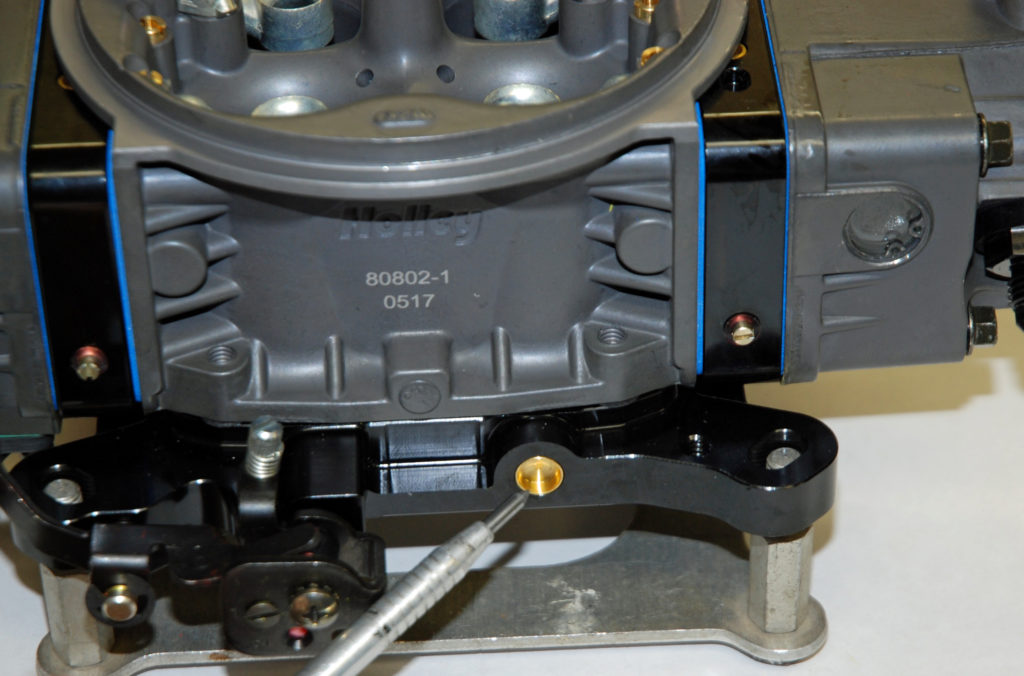

The weight reduction alone is impressive (roughly 38-percent lighter than the predecessors). Externally, the carburetor includes a base plate machined from 6061 billet aluminum. This allows for a superior gasket sealing surface on both ends—carb body to baseplate, and baseplate to intake manifold. You can also see the elongated mounting holes on the baseplate.

Why? It’s a simple and ingenious solution to an old dilemma: The slotted mount holes allow you to use the carb on a standard 4150-series intake or on an intake designed for a Dominator (no adapter is required).

The baseplate also incorporates a purpose-built boss that can be machined (opened up) to provide for a vacuum source, if needed.

Perhaps the best part about the billet baseplate is its toughness. With older carburetors, you occasionally come across cracked or broken baseplates (almost always caused by over-tightening, and usually with tools that prove too big for the job).

The new billet baseplate is much more robust.

The throttle lever setup is definitely a winner from the tunnel ram perspective. It’s an all new-configuration with all of the street-oriented brackets and attachment points like the kick-down brackets removed.

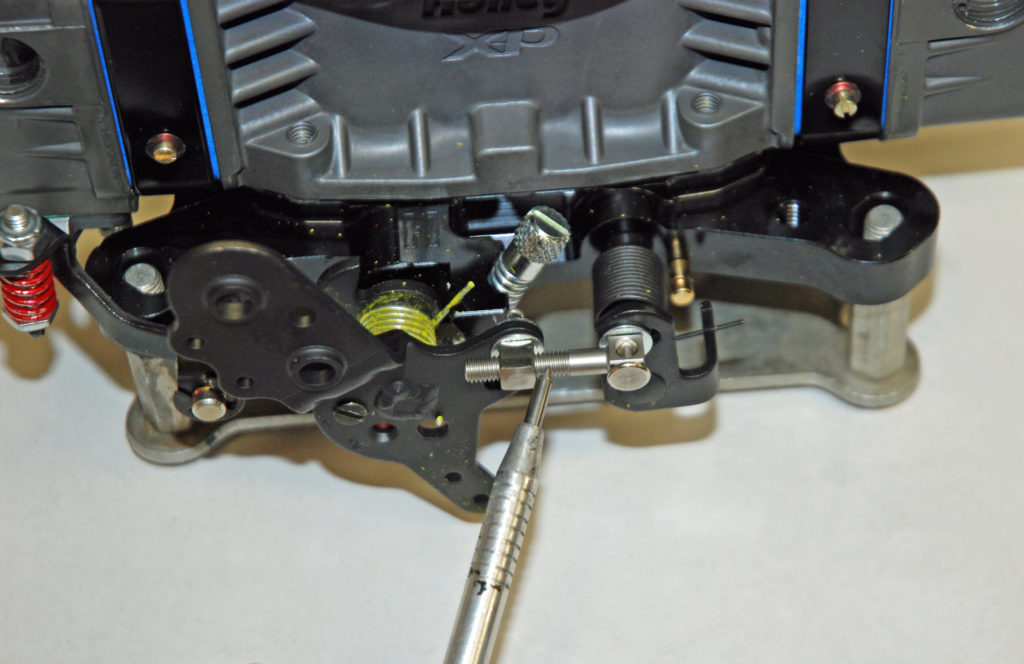

This dramatically simplifies the carburetor in a high performance application, but that’s not the end of it: Holley also engineered an easily adjustable secondary linkage. The adjustable secondary link is manufactured from stainless steel and can be set up as either a progressive secondary opening arrangement or as a 1:1 arrangement. The primary and secondary idle speed adjusters now have knurled knobs, allowing for easy hand adjustment (no tools necessary).

It might seem like a small thing, but the primary throttle shaft is now capped which positively prevents vacuum leaks.

Holley provides a machined accessory-mounting hole that makes it easy to add an adjustable primary throttle stop. There’s also a new secondary pump cam lever to provide for a positive throttle stop on the secondary side.

Then it gets better.

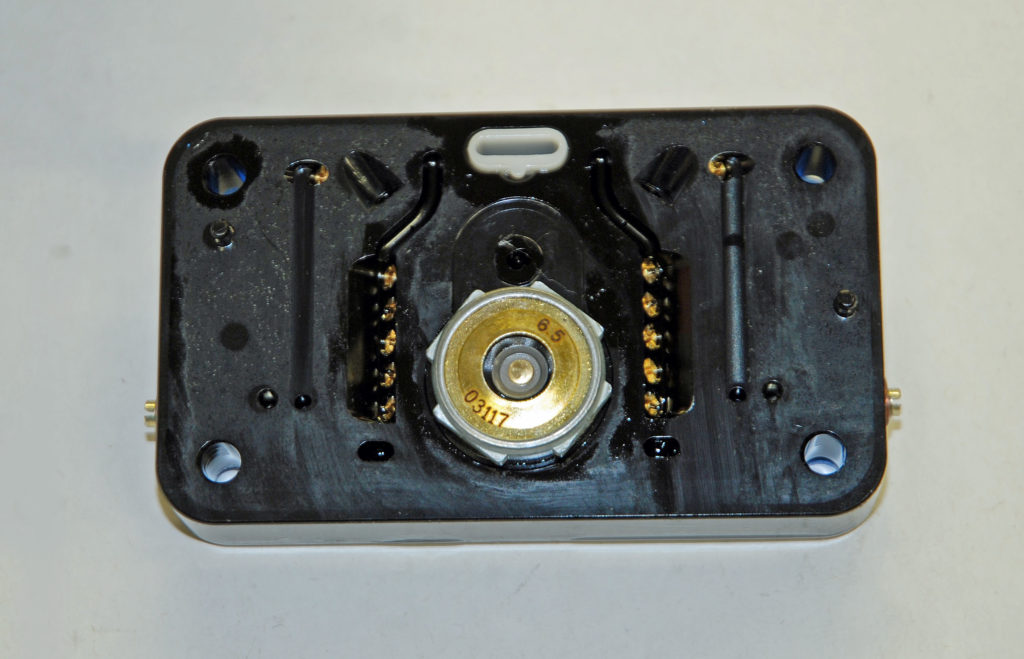

Both the primary and secondary metering blocks on the Holley Ultra XP 4150 carburetors are machined from 6061 aluminum.

This is a great addition when you consider the wear and tear a set of metering blocks go through, particularly in race applications.

And perhaps most obviously, sealing is improved on the new carb design.

Holley also added a handy pry slot on each block for easier disassembly.

The fuel bowl capacity has been increased 20 percent. In turn, the added volume reduces the chance of fuel starvation.

When you examine the bowls (see the accompanying photos) you’ll note there’s a special “shelf” located beneath the needle and seat. The idea here is to minimize fuel aeration.

A trough has been engineered into the bowl to direct fuel to the jets. This helps to keep them covered, which in turn, stabilizes the air/fuel ratios. In addition, the bowls are baffled internally. This keeps fuel slosh to a minimum when you’re getting on the throttle or burning corners on a road course.

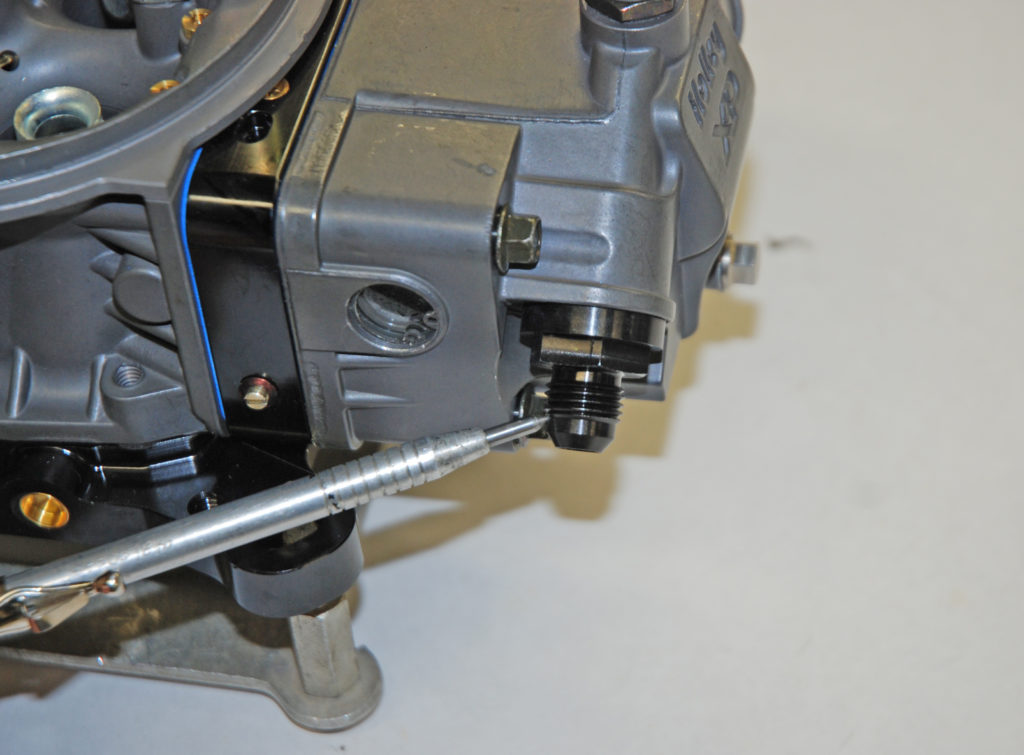

Externally, the bowls now have big see-through windows that allow for easy float settings. The bowl inlets are now machined in 8AN (O-ringed). That allows for a wide variety of plumbing options, and like the Dominator carbs of old, the bowls are threaded and tapped on either side. Holley includes AN plugs on one end of each bowl and a -6 AN to -8AN fitting on the opposite end (which obviously accepts a -6 AN fuel line).

One incredibly great new feature is an easy-to-access drain port on each bowl (it’s obvious that Holley was paying attention to racers here).

New Fuel Injection-Inspired Integrated Idle Bypass Valve Simplifies Tunnel Ram Carb Setup

Setting up carbs on a tunnel ram has always been tedious. Holley’s new integrated idle bypass valve helps immensely. This valve is similar to what you’ll find in several fuel injection applications. In a fuel injection setup, the idle bypass keeps airflow up when the throttle is closed. If you recall, with older carburetors, this was accomplished either by drilling holes in the throttle plates, or adjusting the curb idle screws.

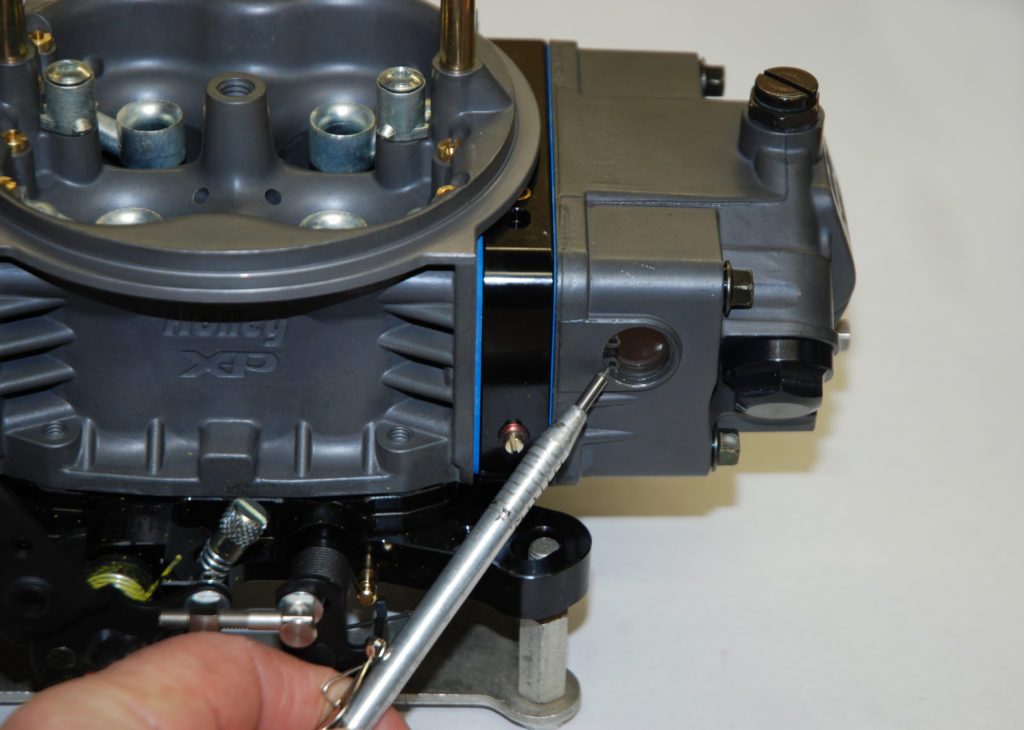

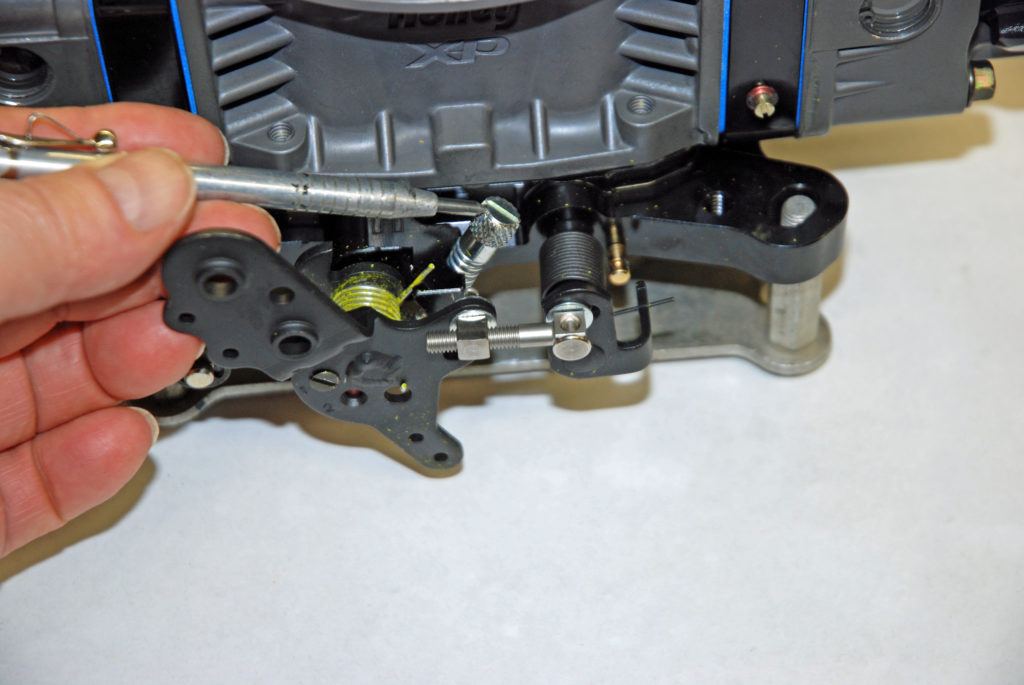

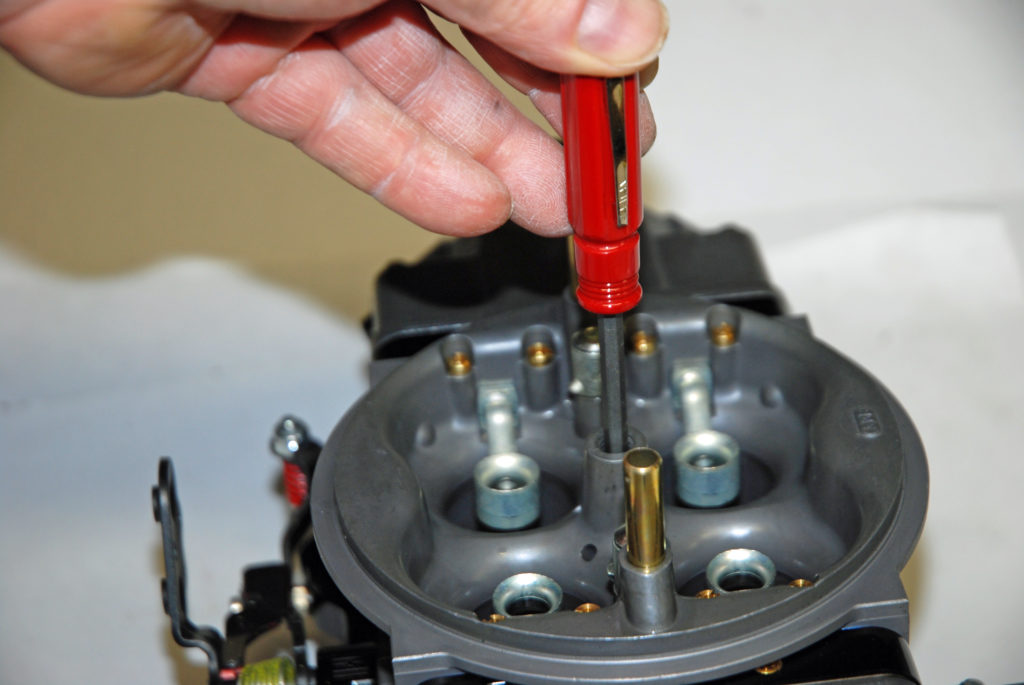

With a radical (big duration and/or big overlap) cam or with a tunnel ram, you could get in trouble by opening the throttle too much, exposing the transfer slot. That doesn’t happen here. The idle bypass is pre-set by Holley and can be fine-tuned easily with a screwdriver. Holley even includes the screwdriver with each carb! [NOTE: Holley recommends setting the idle bypass before touching the curb idle screws.]

Okay, but where in the world is this new valve and where do you set it?

Holley installed the idle bypass valve adjustment screw just underneath the air cleaner stud. If you use the stud, simply remove it. Look inside the stud boss and you’ll find a flathead-screwdriver slotted screw. Simply turn that screw to set the idle bypass valve. With this setup, there’s a good chance you won’t have to touch the curb idle (speed) screws at all.

A Topside Facelift

On the topside the new little double pumper carb body looks a lot different than earlier 4150 examples. The venturis have been contoured. Holley notes that this provides for balanced airflow that in turn allows for increased power.

You can also see that the air bleeds have been moved outboard. This allows for a smoother transition of airflow from the top of the carburetor into the venturi. Obviously, the air bleeds are adjustable. The four outermost air bleeds are for the idle circuit while the four inboard air bleeds are for the high-speed (main) circuit.

The purpose of the high-speed air bleeds is to emulsify the fuel before it enters the discharge nozzle (where it is discharged into airstream in the venturi). As the air bleed size is increased, the air/fuel mixture leans out. When the size of the high-speed air bleed is decreased, pressure across the main jets will decrease. In turn, this pulls more fuel through the main system, which translates into a richer mixture. Holley says the high-speed air bleeds act as an anti-siphon device that prevents fuel from dribbling into the venturi when the airflow is reduced or stopped (throttle closed). Holley also notes that, at high engine speeds, the air/fuel mixture must be on the rich side in order to prevent engine carnage (high speed lean out).

When it comes to the idle air bleeds, keep in mind the idle system provides fuel at idle and low engine speeds. Under these conditions, the engine requires a richer fuel mixture than it does at high speed. With a lean idle mixture, combustion is slow and irregular which results in a rough idle.

Decreasing the size of the idle air bleed richens the mixture by increasing the pressure drop in the system.

Increasing the size of the idle bleed leans the idle mixture by reducing the pressure drop across the idle air bleeds. Holley says the same can be accomplished by backing out the idle mixture screws, which will increase the pressure across the idle air bleeds, effectively pushing more fuel from the idle well. This creates a richer air/fuel ratio. Holley recommends making adjustments using the four idle mixture screws.

The New Metering Blocks: Engineered for Tuning

More good news for tunnel ram users: The new metering blocks are engineered for tuning. Aside from the standard replaceable jets and power valves, the metering blocks allow for tuning the idle feed restrictions, emulsion bleed restrictors and the power valve channels.

Holley determines the idle circuit calibration by the diameter of the idle feed restriction (IFR) coupled with the idle air bleed.

The pair of idle feed restrictors is nothing more than a jet for the idle system while the air bleed serves as the airflow-regulating orifice.

Holley says that by turning the idle mixture screw(s), you vary the volume of air/fuel emulsion being discharged into the intake manifold, not the actual air/fuel ratio.

Given the new design of the metering block, it’s possible to change the idle feed restrictor size to compensate for a large (big duration, high overlap) camshaft and/or tunnel ram combination. With this kind of combo, the intake charge is often diluted at idle. The dilution is created because the intake charge is pulled out the header due to a late closing exhaust valve. To bring back idle quality (and sensitivity) to the idle mixture screws, the idle feed restriction size must be increased.

Holley has included power valve channel restrictions in each metering block.

There are two restrictions visible when the power valve is removed. These restrictions meter the flow of fuel into the main carburetor well. It is the diameter of these restrictions that dictate the amount of fuel going into the circuit. When the size of the restriction is changed, the air/fuel ratio will change at wide-open throttle. When the power valve is closed at idle or at part throttle, the power valve restrictions won’t have an effect.

There are 10 emulsion bleeds on each metering block.

Emulsion bleeds can affect power, but that’s dependent on the specific engine combination.

If you wish to tune by way of emulsion bleeds, then it must be done on a dynamometer where you can carefully monitor the air/fuel ratio. Holley offers emulsion bleed tuning components.

As you can see, these new Ultra HP Holley carbs are jammed with features every racer use. The new XP series are definitely tunnel ram friendly!

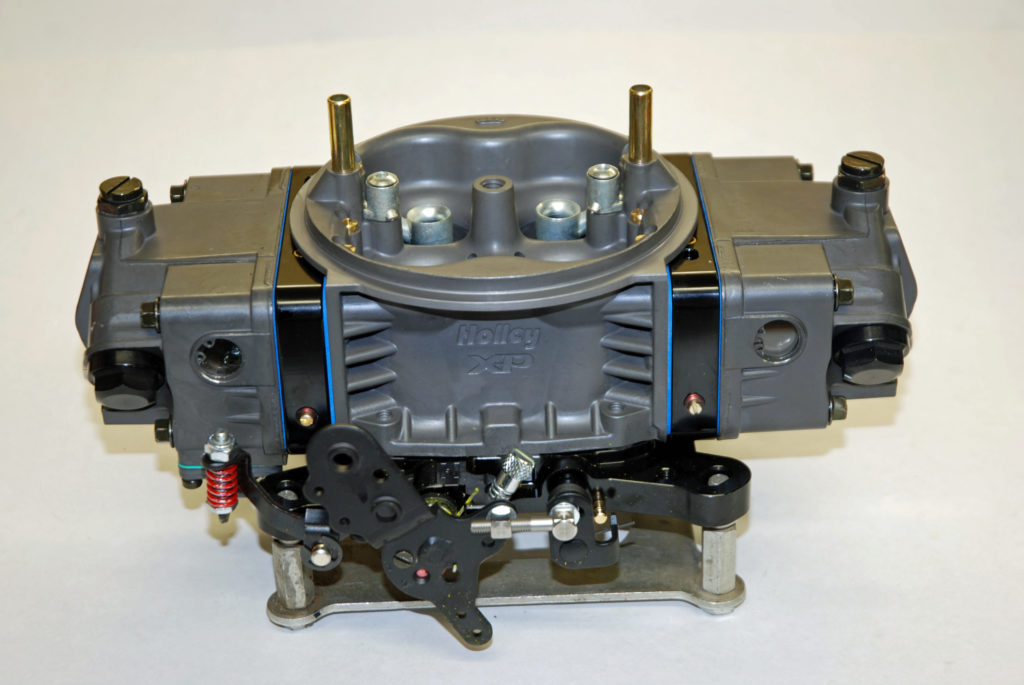

For most high horsepower tunnel ram applications, this is an outstanding choice when it comes to carburetors: Holley’s latest 650 CFM Ultra XP carbs.

…

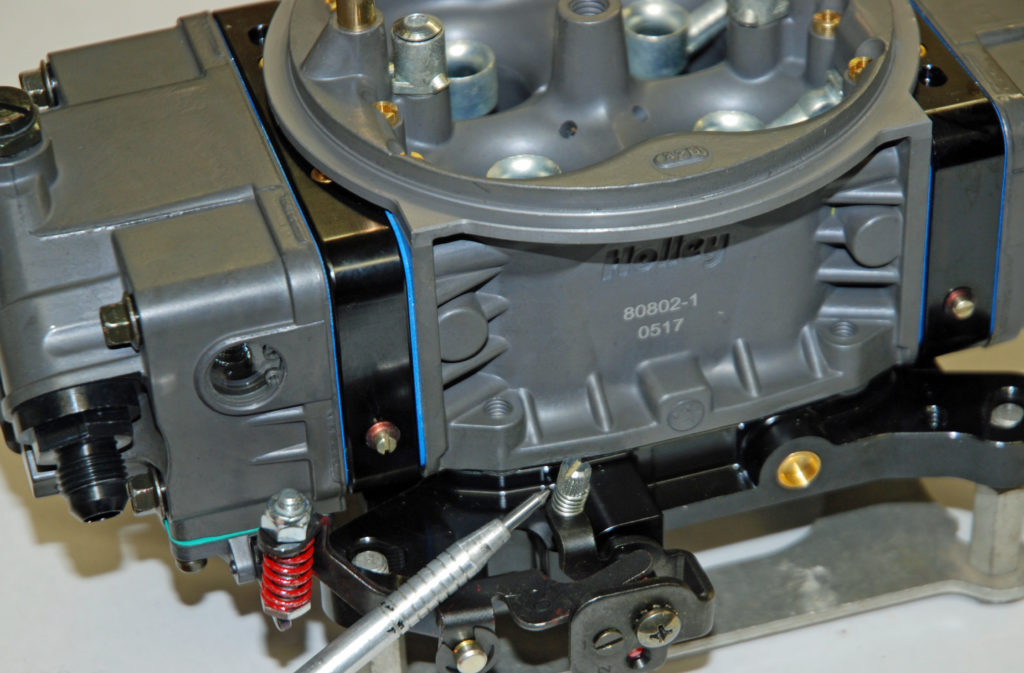

Yes, they look different with the new hard anodized finish.

…

The real key with these new carburetors is their adjustment capability. Equally important, the XP series carbs are very easy to tune and adjust.

…

Note the new bowl “windows”. You no longer have to deal with a sight plug. Instead, you can see right into the bowl to set the fuel level. There’s a window on each side of each bowl too which is handy in 2X4 combos.

…

Holley added a simple, easy to access bowl drain on each of the fuel bowls. Obviously, these carbs are racer-friendly.

…

When plumbing a tunnel ram, it’s convenient to have bowl inlet fittings can be plumbed from either side of the carburetor. Fittings are now -8 to -6 in size (-8 at the bowl, -6 at the male fitting). This eliminates the special Holley thread once used on bowl fittings.

…

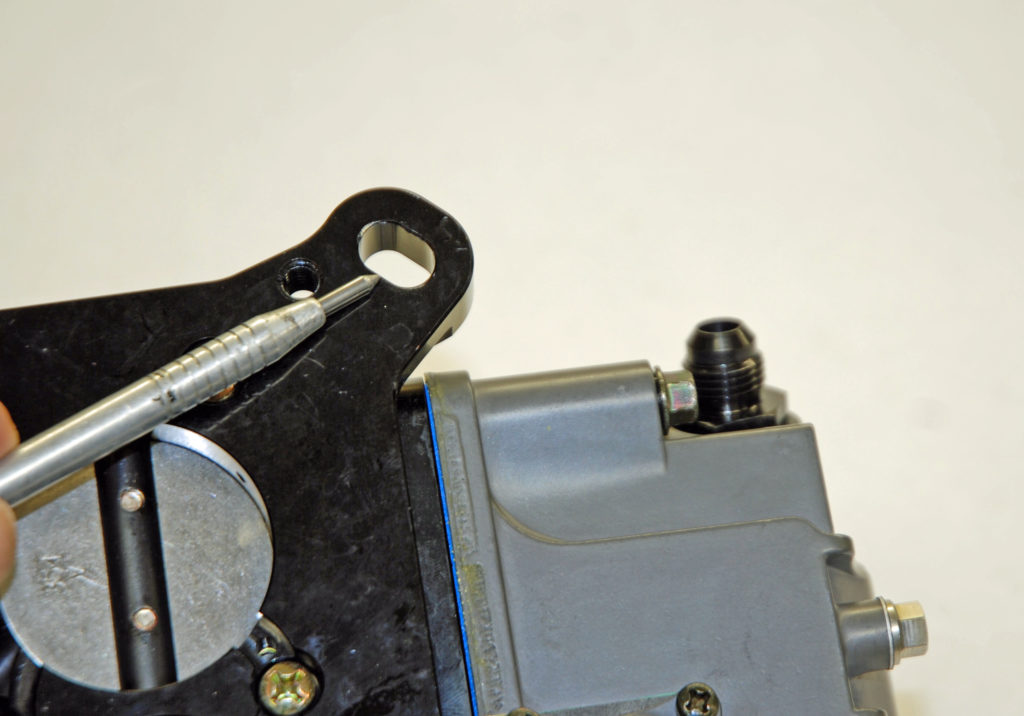

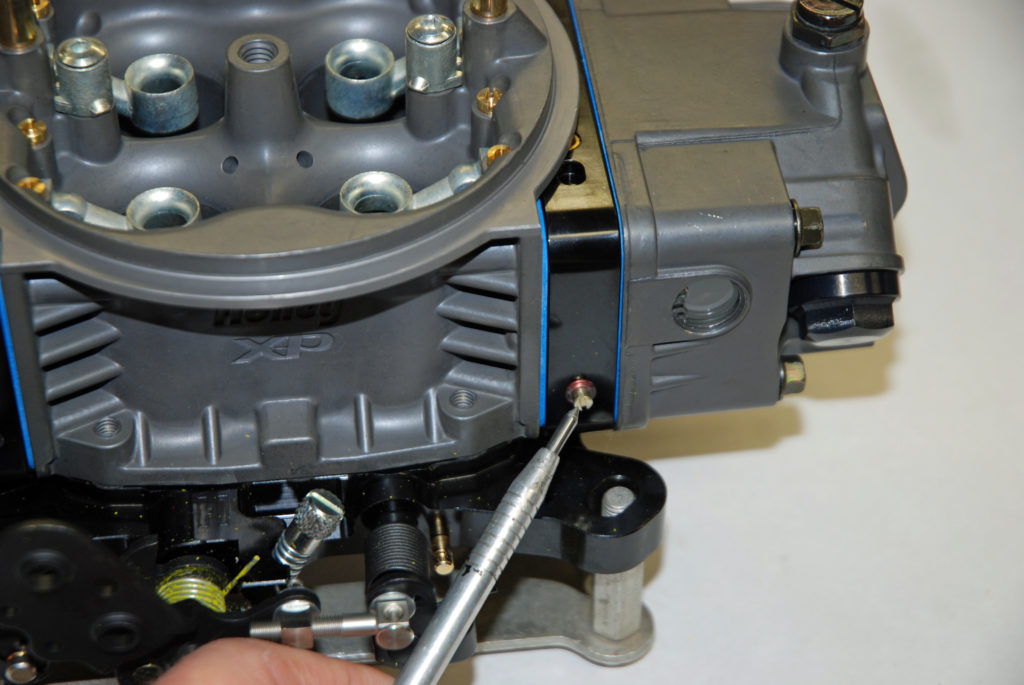

Throttle shafts are now positively sealed (as shown here).

…

Here’s another simple (and outstanding) idea: The baseplate mounting holes are now slotted. This means you can bolt the 4150 to an intake manifold designed for a 4500 Dominator without using an adapter.

…

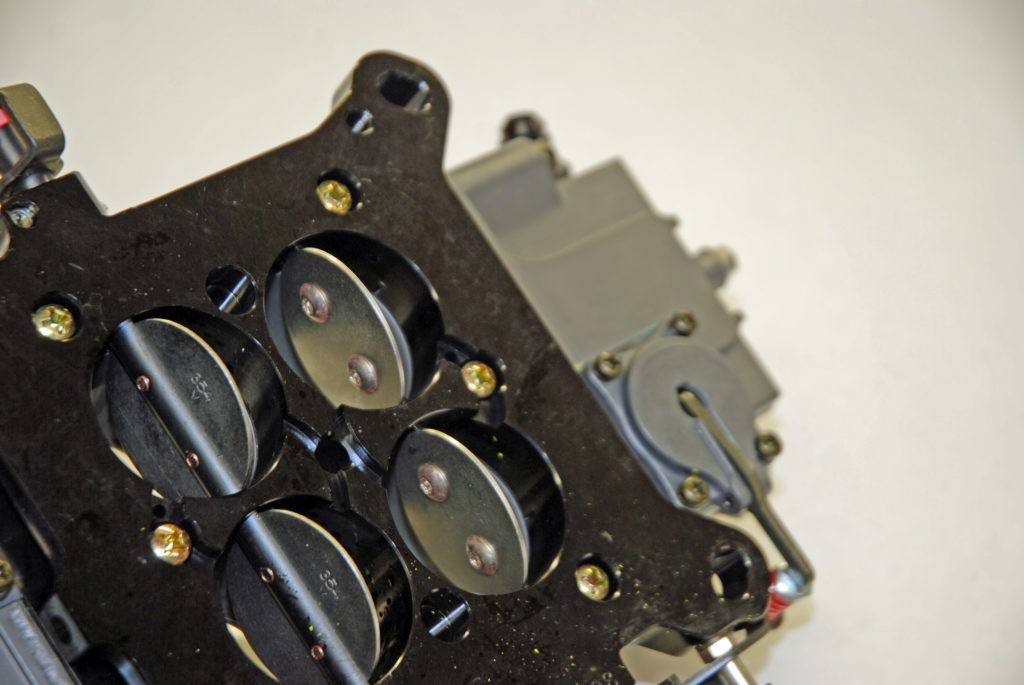

Holley uses smooth button head fasteners to attach the butterflies. The baseplate is billet aluminum.

…

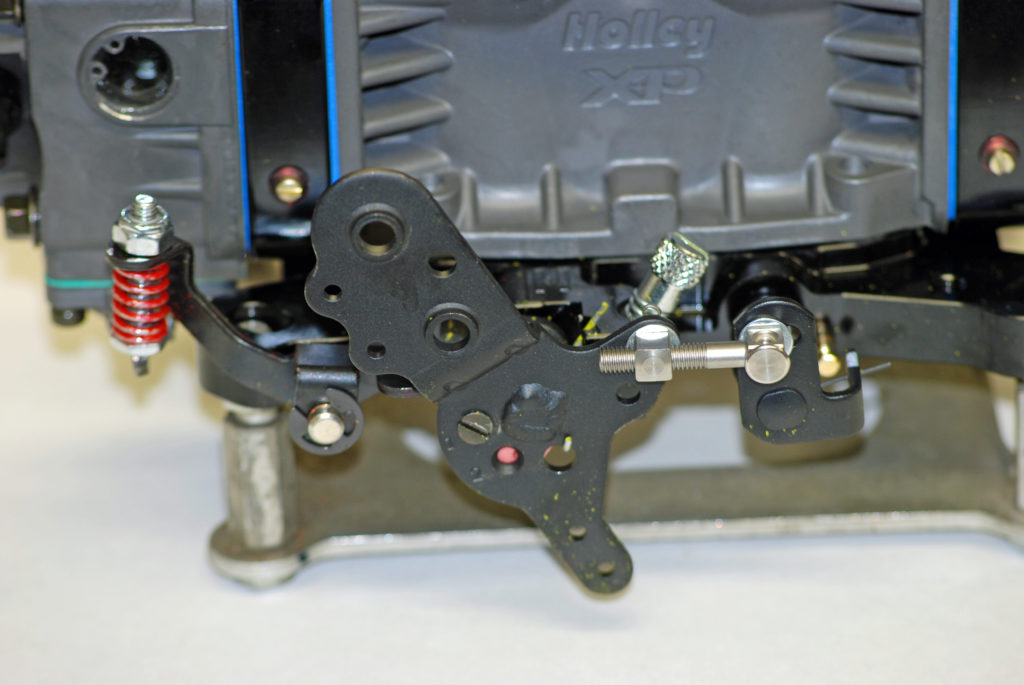

The secondary linkage is all-new, too.

…

It’s incredibly simple, easy to adjust and can be setup to go from progressive all the way to 1:1 (again, another tunnel ram friendly feature).

…

Typical of most late model high performance Holley carburetors, there’s an idle speed screw for both the primary and secondary throttle shafts.

…

That’s the idle speed screw for the secondary throttle blades. Yes, they can be set by way of a screwdriver, but as you can see, the knobs are knurled. That means you can set idle speed quickly by hand.

…

Another carryover feature from past Holleys is the capability to adjust idle mixture on both the primary and secondary side of the carburetor.

…

Holley’s latest XP series 4150 carburetors are equipped with a series of replaceable air bleeds for the idle and main circuits. The pointer shows the location topside on the carburetor (the inboard bleeds are for the main circuit).

…

When it came to improving airflow, even the accelerator pump shooter screws didn’t escape Holley’s attention. As you can see, they’re now smooth, round button head jobs.

…

Boosters fitted to these carbs are down leg models. Typically, a down leg booster provides for an improved fuel signal (another tunnel ram friendly feature). Note too the carefully contoured main carburetor body. Holley spent a lot of time working out the shape in order to improve airflow.

…

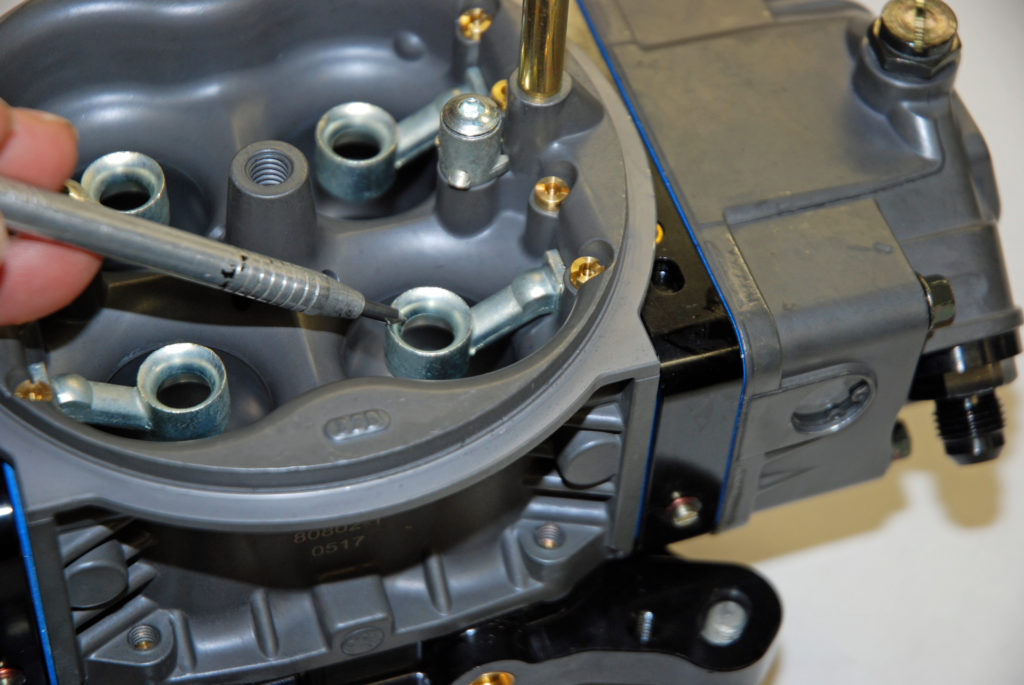

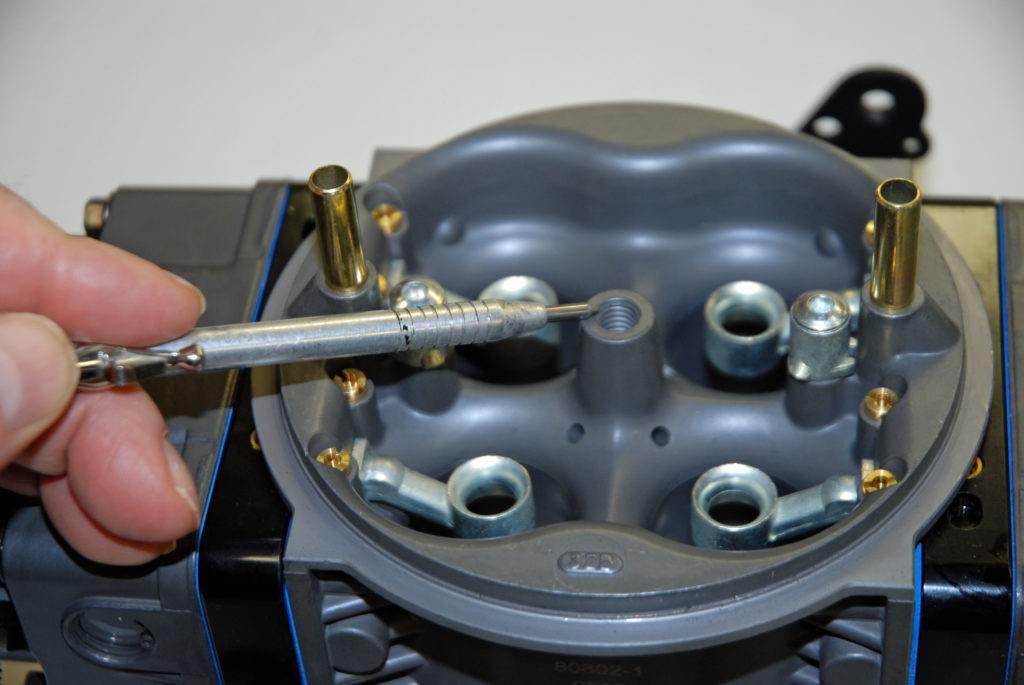

This is the typical air cleaner stud location. But when the stud is removed (not a big job) or not installed (as shown here), there’s an adjustment port for the idle bypass system. It’s a slick way to overcome combinations that don’t like to idle.

…

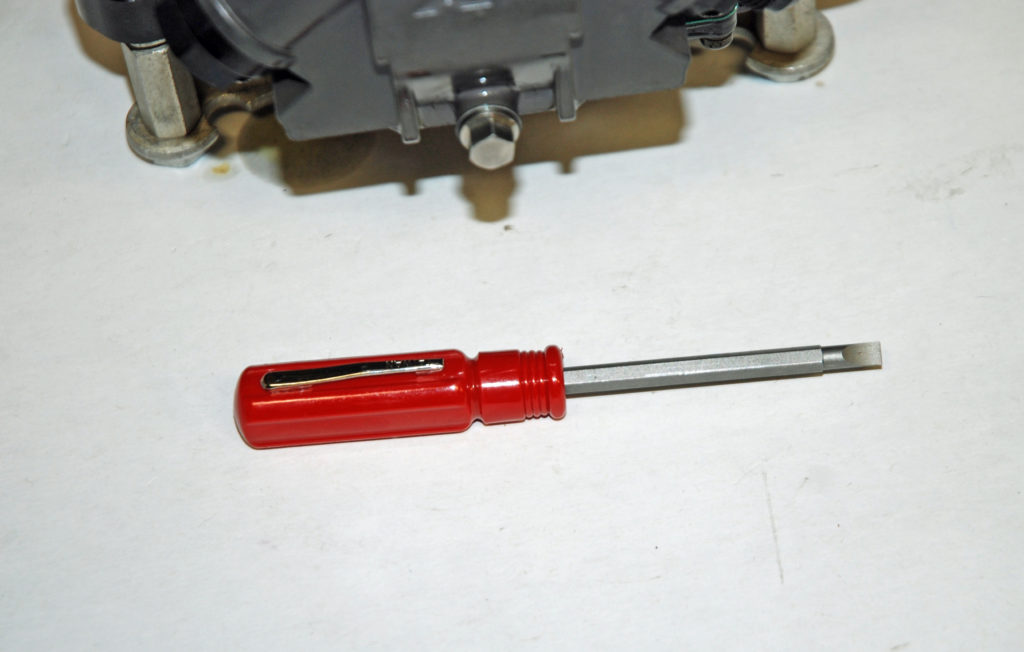

Holley provides a slick little screwdriver designed especially for the task of adjusting the idle bypass system.

…

The included screwdriver works like this. 😉

…

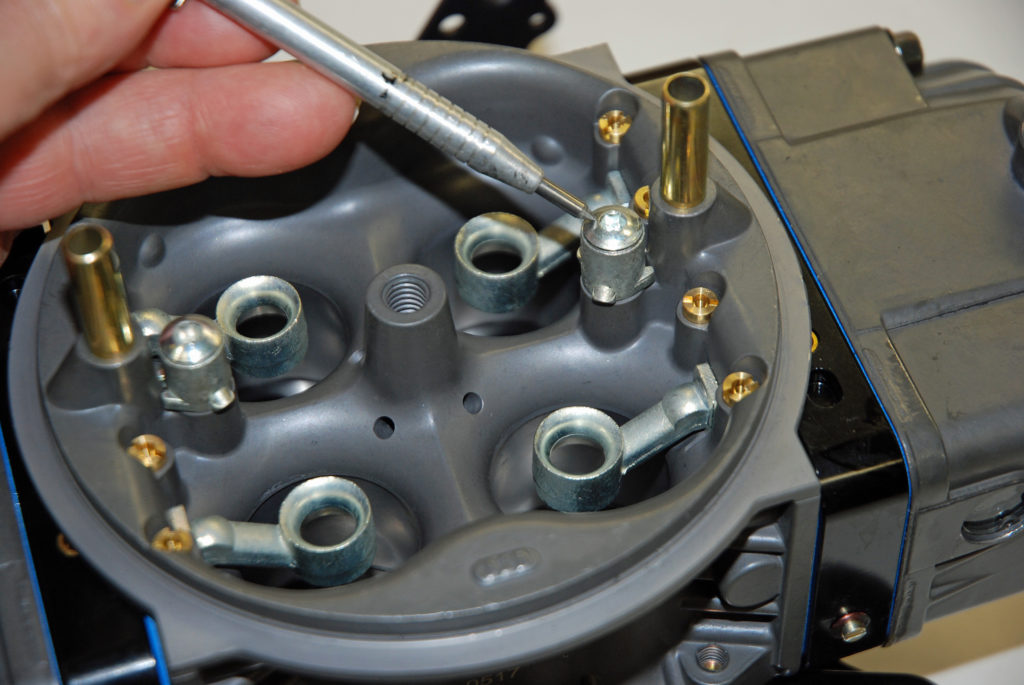

Metering blocks are billet aluminum, and they’re designed for maximum adjustment capability.

…

Here you can see the replaceable emulsion bleeds.

…

The pointer locates the replaceable idle feed restrictor. Not shown are a pair of replaceable power valve restrictors (they’re visible once the power valve is removed). The text of this article offers more info on the adjustment capability found within the metering blocks. It’s considerable.

…

Inside the bowl, Holley included a special fuel “trough” that directs fuel to the jets. Floats are notched front and rear.

…

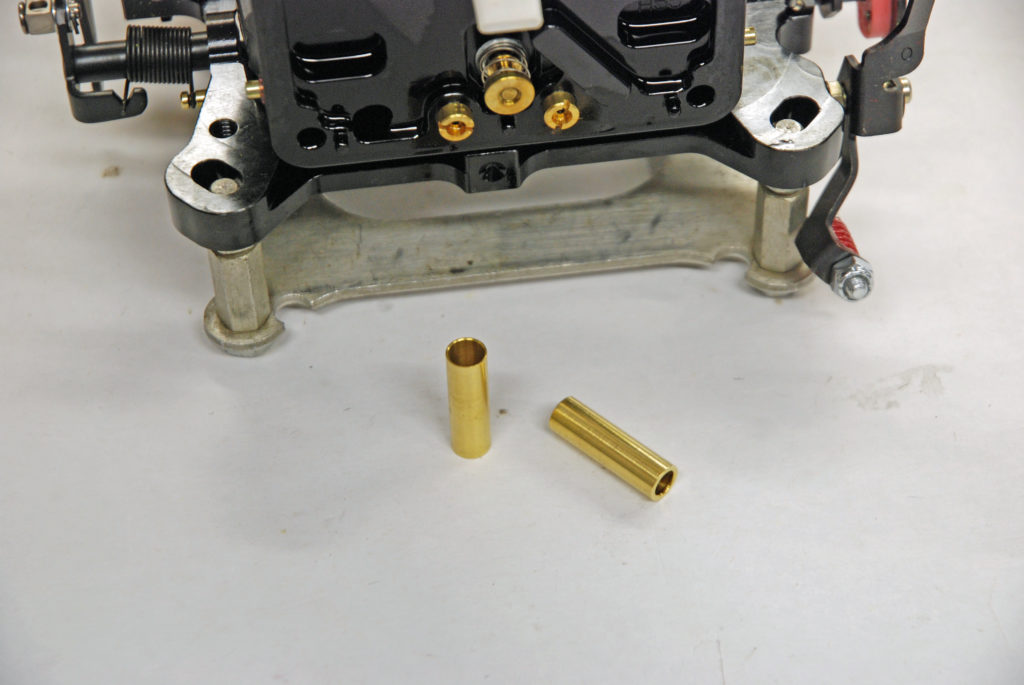

The notch on the rear float allows you to use a set of jet extensions, which are included with the carburetor.

a lot of these inovations were on Qft carbs, Did Holley buy Qft out? Every thing on XP series looks like great improvements, except those short vent tubes. they will cause flooding afterthe burnout. I have already addressed this problem on my tunnelwedge with 660s dinosaur. I think they are perfect 2×4 carbs & if holley fixes this, there wont be anything left to improve.I hope the price is not first born.

Install longer ones, or run a hose that TIGHLY fits on both, about 6″-8″, and make a hole in the middle for higher vent.

Hello Wayne Scraba,

I’ve been reading your unique methods of Automotive Journalism for quite a while now. I won’t put a number on that statement for fear of it breaking my perfect state of denial in regards to the aging process . Displaying the intricate details on a carburetor requires an extra measure of skill and these photos are nicely done as well !

For me, your work on this story was good reading because I purchased a new Holley 850 Track Warrior for my Christmas gift. I don’t need to tell you about the dozens of good choices based on the XP and 4150 Holley Series. You noted all of the special features that the Ultra HP Series has to offer and the Hardcore Grey wasn’t exactly what I was looking for but it’s finally starting to grow on me. I had some reservations about the coating durability at first but I do think it’s going to still look good Years down the road…or strip.

I was going to get the 750 cfm Track Warrior for my application ( 351 Cleveland 4-V Old School Iron heads featuring Endyn-Widmer full high-port conversion with Titanium valves, Quench Chambers, 12.4:1 CR , Reed Solid Roller 0.645” I&E gross lift, 298* int/302*exh. duration) with 3500+ C4 and Strange/Detroit Locker Pro Iron assembly 4.11:1 turning 35 spline ST alloy axles.

I made a last minute decision to go with the 850 because a 393” Eagle forged stroker kit will most likely feel at home in my 0.020” OEM 4-bolt block. The 1970 Mach1 will need the extra torque.

But getting back to the induction system, I’m using a single plane Edelbrock Scorpion that was originally included with the Endyn High Port package. Naturally it’s perfectly port matched with some impressive plenum and interior port wall divider “changes”. LOL . It should work well but CARB EXPERT isn’t on my resume and I would welcome all tech advice from Wayne or the readers. Comparing the Ultra HP 650 details in this report and my new Track Warrior 850, the HP 650 includes the idle air bypass adjustment but none for the Warrior. The 650 baseplate has elongated bolt holes, round holes on the 850. The fuel bowl drains really should be standard on EVERY Holley carb. Or at the very least, an AFFORDABLE OPTION because it’s not just a special touch that makes time spent alone fondling your float bowls a full blown perversion involving zinc additives. Being able to drain your boiling bowls while reducing the risk of torched eyebrows and raging two car garage infernos. SERIOUSLY…..SAFETY !!

The Track Warrior is a modestly priced COMPETITION CARBURETOR featuring proven components like billet alloy throttle baseplate and metering blocks for durability with precision machined gasket mating surfaces. Mechanically actuated secondary throttle bore venturi plates.

This carb has nearly all of the features that makes it ideal for many Sanctioned Drag Racing classes. The clear sight glass “windows”on both float bowls makes setting the critical fuel levels quick and accurate. I also feel like having quick visual access to the fuel levels is another important safety feature in the unlikely event of excessive / unregulated pressures resulting in a potentially dangerous fuel spill. Unfortunately, all models aren’t equipped with this simple yet effective feature.

I feel like one of the most important technical details about, and my main reason for purchasing this Holley Track Warrior 850 CFM Competition Carburetor P.N. 0-67201BK (Black Anodized Billet) is that it’s built around the HP Series Alloy Main Body. It features smooth flowing sculpted throttle bores WITHOUT A CHOKE OR THE REMAINS OF A USELESS CHOKE HORN to impede, disrupt and impact the harmonious intake charge flow velocity requirements associated with Professionally Optimized beyond the original Ford Engineering (‘69-‘70) sustained target tuned for 6400 rpm’s @ 3750 FPM mean piston speed. That little equation helped load up GM’s limp wristed DOUBLE HUMPs feeling the dry hump pain of defeat every weekend. But no worries…Chrysler sat upon a sad Pentastar and joined in with bittersweet blues about not enough 1320 left to catch canted poly angle Cleveland singing that victory song in perfect 9500 pitch ☮️AND THE BEAT GOES ON…:

A quick review was suggested but that went away several paragraphs ago. I’ve got more to review but to avoid any further boredom related harm to the readers, early conclusion shutdown is eminent. Just one high priority item left to share….Money and getting what you needed /wanted paid for

RQ14

A quick overview of my purchase;

I just purchased (2)- XP 750 carbs for a Tunnel Ram setup I’m running. Upon first fire up my idle rpm was a steady 4000. After reading the instructions I proceeded to adjust my idle speed. I first attempted this with turning the idle bypass in a 1/4 turn in on the one carb when I attempted the second carb the screw was turned in all the way and bottomed out. At this point I went back to the first carb and turned the screw in all the way to count the factory setting of 2 1/4 turns out from bottom. I equalized both carbs and proceeded with my idle tuning. I was unsuccessful with getting the idle under control with the idle bypass valve. I moved on to primary and secondary idle speed screws which I was able to get the idle down to 1200 rpm which is probably acceptable for this engine but the mixture is fat. I would like to know all factory settings so I can start over. Am I having this trouble because of the two carburetors? Is there a different factory settings for use of two carburetors on a tunnel ram if so, could you provide so I can proceed? My phone number is 716-472-9561. Thank you in advance, Chris Fronczak