Remember when your mom told you not to run through the house with scissors or to stop sticking that screwdriver in the electric outlet? OK, maybe that was us. But there is one thing that everyone should be taught, and that’s how to use the right tools to install and remove a harmonic balancer.

For example, Summit Racing makes a dandy harmonic balancer puller and installer tool just for GM LS engines. The tool comes with a three-jaw puller plate with brace rods; balancer installation tool; and a balancer wrench with heat-treated 4140 chromoly studs.

The wrench also comes in handy to rotate the engine during assembly or cam degreeing.

Using the Summit Racing LS balancer tool is easy—and works much better than that hammer you thought about using.

The Summit Racing LS harmonic balancer installer and removal kit comes with a balancer installation tool, three jaw puller, and a balancer wrench.

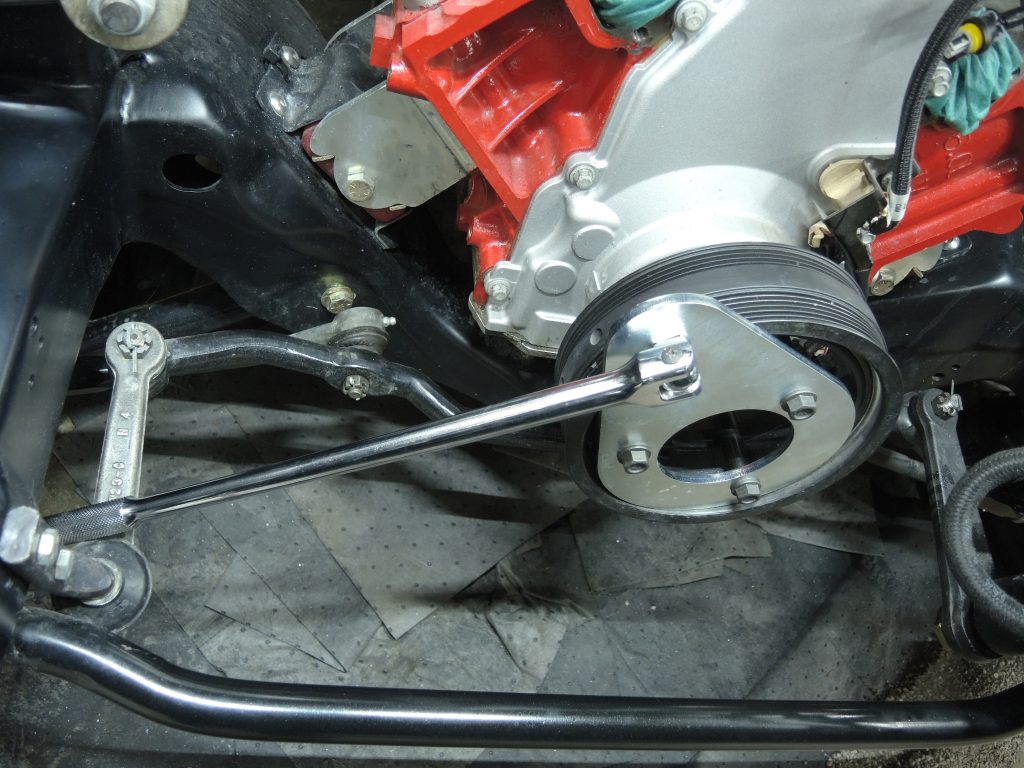

The balancer wrench fits between the lower spokes of the balancer. A 1/2-inch breaker bar is used to brace the balancer against a frame rail or suspension component. Make sure you don’t brace against brake lines, fluid lines, or other vulnerable parts.

With the balancer braced and unable to turn, remove the balancer bolt with a ratchet or impact wrench.

The three jaw puller uses a brace rod that fits in the tool and the inner bore of the crank snout. The tool comes with four different length rods—choose the rod that works with your application.

The crankshaft bore seat is deep in the crank snout.

You want the brace rod to extend at least an inch beyond the pulley hub.

The jaws align with the relief areas cast into the LS balancer, and apply even tension against the crank snout as the tool is tightened and the balancer removed.

Once tension is established against the brace rod, use a ratchet to remove the balancer from the crankshaft. Don’t use an impact gun for this procedure as excessive force can damage the cast balancer.

To reinstall the balancer, thread the installation tool into the threaded bore of the crankshaft snout by hand until seated. The balancer wrench can be used here to stop crankshaft movement.

It would be nice to show the removal and installation on YouTube. Also could provide the part number and cost.

Hey Jim. That part number is SUM-900135. The current price is $47.99.

https://www.summitracing.com/parts/sum-900135/overview/

Does anyone know what size three jaw puller they sell at Harbor freight to remove the balancer? They sell a 4,6,8 inch puller. It’s a 4piece puller tool number 63760. I was planning on purchasing the 8 to remove my LS Gen three balancer.

In search of this kit. Sooner rather then later. Any one else make this kit? Summit says 2 to 3 months to get.