Heavy-duty jobs like engine swaps, transmission repairs, crate engine installs, and other serious projects usually require some sort of hoist to ensure you don’t damage your vehicle—or yourself.

That’s why many gearheads have a good quality engine hoist in their shop or home garage.

Seasoned gearheads already know the value of a sturdy, strong engine hoist. But if you’re new to the hobby—or you’re ready to take your wrenching skills to the next level—a hoist is a must-have tool for lifting engines, transmissions, and other parts out your car or truck. Choosing a hoist that will work best for you comes down to a few simple steps:

***

Picking the Right Engine Hoist Design

There are three main types of designs:

1. Hydraulic Engine Hoists

Hydraulic hoists are the most common types you’ll find at places like Summit Racing.

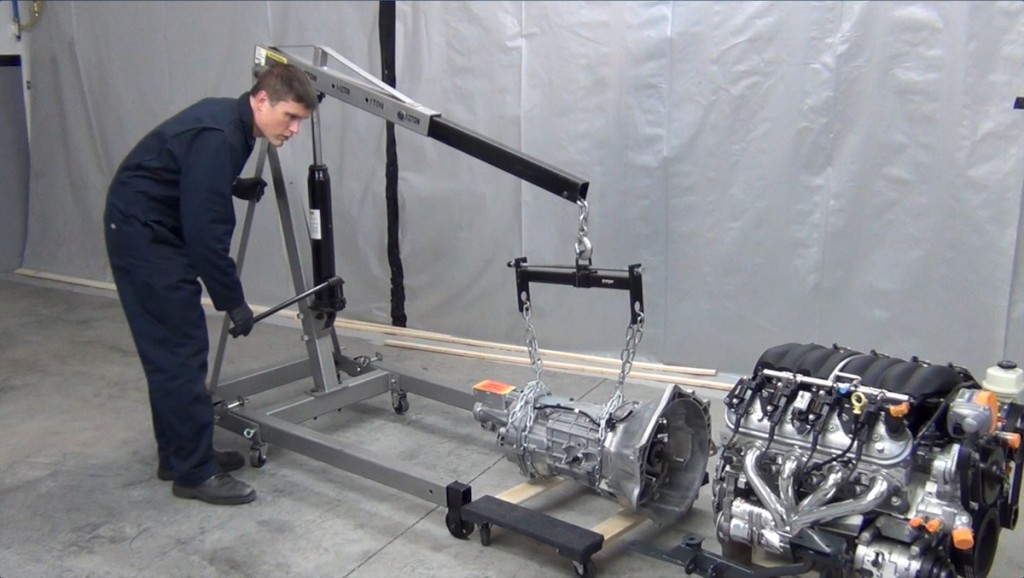

These hoists consist of a set of legs, an upright frame, and an adjustable boom with a chain and hook. As the name suggests, hydraulic hoists incorporate a hydraulic bottle jack to lift and lower the load. You typically insert a jack handle at the bottom of the unit and manually pump the jack to increase hydraulic fluid pressure. This raises the hoist’s boom, which holds a grab hook to attach to the engine itself.

Hydraulic lifts roll around on casters, so they’re more mobile and versatile than other jack designs. However, depending on the type of hydraulic hoist you choose (more on that later), they can take up more garage floor space than other hoist styles. They also require flat, stable ground in order to be used safely and effectively.

Still hydraulic hoists are the most popular styles for good reason:

- Lifting pace is quicker than most chain hoists, although it can still take a bit of time to complete the process

- Usually less expensive than electric hoists with comparable lifting capacities

- Easy to operate

- Typically have higher lifting capacities than other styles

- Can be used indoors and outdoors as long as there is a flat, hard surface

- Minimal maintenance

***

2. Chain Hoists

The next most popular hoist style is the chain hoist—and they’re made by many trusted tool manufacturers, including Performance Tool, Summit Racing, Jet Tools, and Reese Towpower.

Typically used with some sort of overhead gantry crane or girder support, a chain hoist employs a gear system and a set of chains to multiply lifting force. By manually pulling on one chain—the hand chain—it activates the gear system and begins the hoisting process. This gear system includes various-sized sprockets and uses its gear ratio to multiply the lifting force as its applied to the hand chain by the user. A chain hoist has a ratchet or braking system to prevent the attached parts from lowering when the hand chain is not being pulled.

Like the hydraulic hoist, a chain hoist has advantages and disadvantages. It is generally the least expensive option when buying a hoist and the design requires limited maintenance. However, the design is also the biggest disadvantage of a chain hoist. That’s because chain hoists must be mounted to a fixed point above the lifting area. This may require you to make a special ceiling mount or some sort of scaffolding if you’re using it outside. Installation can be tricky.

Carefully weigh the advantages and disadvantages when considering a chain hoist:

- Advantage: Inexpensive

- Disadvantage: Not for loads over 6 tons

- Advantage: Easy to operate

- Disadvantage: Slower than hydraulic or electric hoists

- Advantage: Take up less space than comparable hoists

- Disadvantage: Require special mounting considerations

***

3. Electric Hoists

Though less common than the chain hoists and traditional engine lift, electric hoists are still found in a lot of automotive shops—though they’re common in factories and warehouses.

Still, they are an option and worth a look—we’re particularly fond of the lineup of Milwaukee Tool Electric Hoists.

Like chain hoists, electric hoists use a set of chains to lift the engine. The big difference is electric chain hoists don’t require manual operation. They have an internal motor, which is activated by remote control and provides the lifting power. That makes the electric hoist the easiest and fastest hoist to use, and it’s ideal for shops where frequent lifting is required.

Sounds great, right? So what’s the downside?

Electric hoists cost significantly more than the other styles of engine hoists, especially as the weight capacity requirements go up. An “entry-level” electric hoist will have a small weight capacity and cannot be used for larger engines. As the weight ratings go up, so does the price—quite significantly!

Like the chain hoist, an electric hoist also requires a mounting point. Plus, you need a nearby power source to operate it, making it the least versatile and mobile of the engine hoist designs.

***

Weight Capacity

No matter which style of engine hoist you choose, weight capacity should be the number-one consideration. Typical weight capacities for hydraulic hoists are 1- and 2-ton, although there are bulkier hoists for larger engines. Chain hoists usually have lower weight capacity options.

When selecting a hoist, we recommend going with a higher weight capacity than the actual weight of the engine. For example, many people opt for a 2-ton hoist even though most car engines don’t weight that much. This is because physics tells us the actual weight capability of the hoist can drop as you extend out the engine hoist’s boom. Some manufacturers provide weight ratings with the boom extended to different lengths.

Check for your engine’s weight, and purchase your hoist accordingly. A quick web search should help you nail down your engine’s heft.

***

Foldable vs. Non-Foldable

There is one more thing you should know before making your decision.

If you opt to go with the popular hydraulic design, you’ll be faced with one last choice: foldable or non-foldable. The fold up hoist has become popular as they can be folded up and stored out of the way, saving valuable garage space in the process. For most DIYers, this is a definite plus.

***

Disappointing to see only Chinese product represented in your pictorials. I had hoped for some US goods to help us all out of the rudderless mire we seem to follow>>>

Thank you for the info will be buying one soon.Jim

I am in need of a replacement of my engine hoist but really like to buy one MADE IN THE USA! Thanks.

[…] it can still be daunting to pick the best among them. I have therefore provided you with the buyer’s guide, in which I have highlighted the important aspects worth considering before making a […]

Good summary but I am concerned that my engine will clear a 3 ft height up & over my radiator cross bar if using a 1 ton foldable shop crane as advertised by Harbor Freight.

Another downside I’ve found with the electric chain hoist is the inability to control lifting or lowering speed. When you need to lift or lower something slowly to guide it into place the electric hoist has only one speed-usually too fast.