Compression equals horsepower.

The reason is simple: The more you squeeze the air and fuel mixture in the combustion chamber, the more power you can create. In theory, forcing air and fuel in as small a combustion chamber as possible (measured in volume) will yield maximum engine compression and horsepower. There are a number of ways to accomplish the task. You can buy cylinder heads with small volume chambers already cast or CNC-machined in. You can use dome pistons to effectively reduce the volume of a large combustion chamber or even choose thinner head gaskets.

Or you can mill the heads.

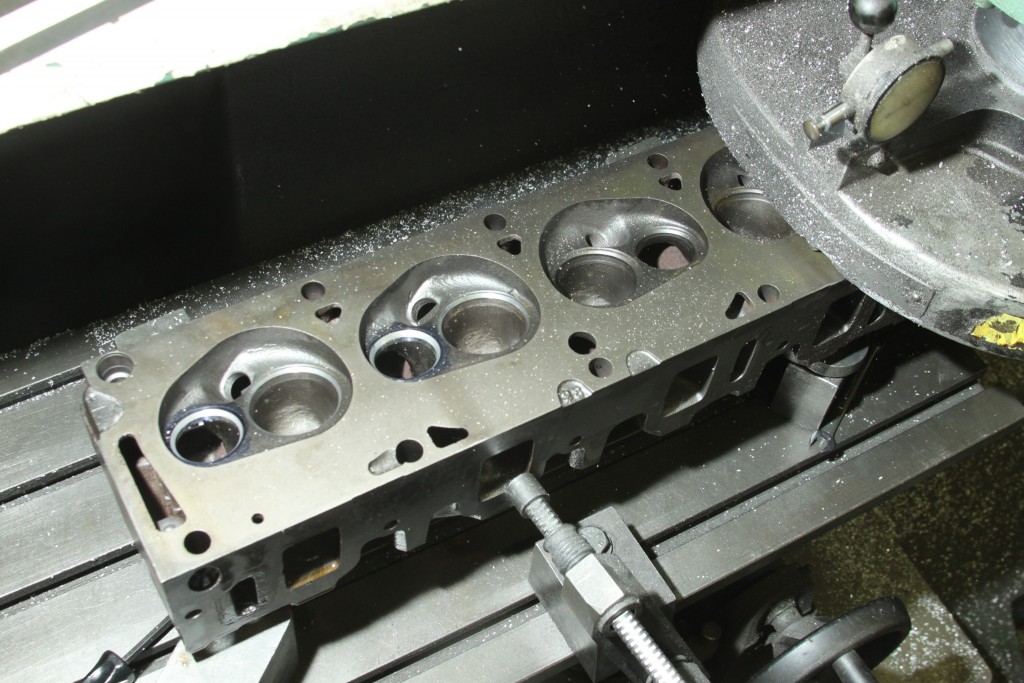

Milling involves removing material from the cylinder head (or block deck surface where the heads and block meet) to effectively reduce the volume of the combustion chambers. This method, which is also used to correct warped or imperfect deck surfaces, allows you to control the size of the chamber so you can get the volume needed to achieve a desired compression ratio. There are a number of calculators like this one available on the Internet to help you determine how much material needs removed to achieve a desired compression.

Milling allows you to build higher compression using flat top pistons, avoiding the potential detonation problems associated with dome pistons. As with any method of increasing compression, you will have to reduce total ignition timing and possibly use higher octane fuel with milled heads to prevent detonation. Proper tuning will tell you how much timing and octane your engine will need.

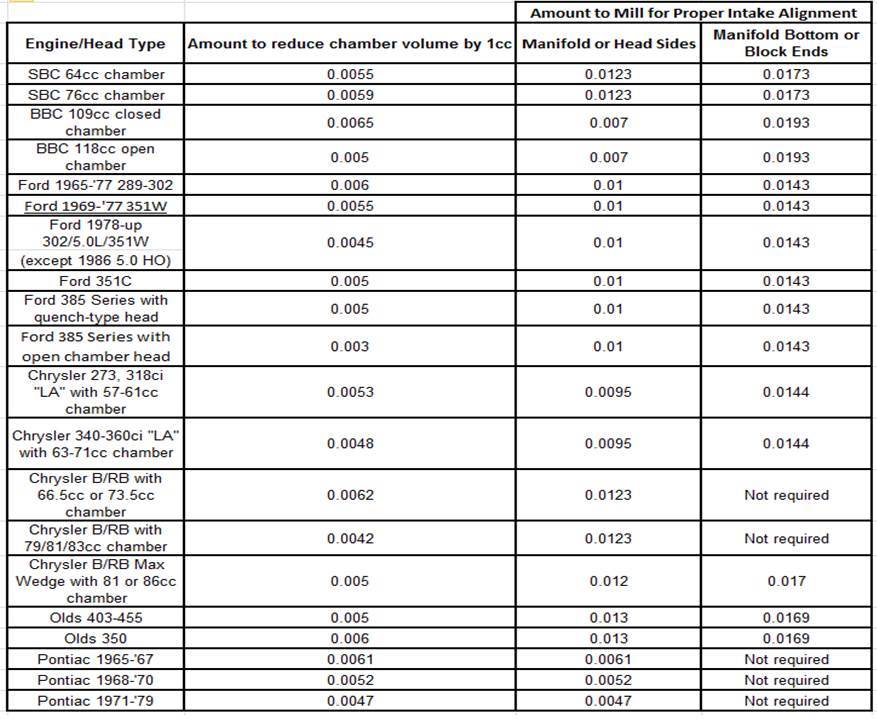

Keep in mind, milling changes the relationship between the heads and/or block and the intake manifold. Depending on the amount of material removed, the intake may also require milling to compensate. To help you determine the proper milling specifications for factory heads on popular classic V8s, we’ve included the chart below. When working with aftermarket cylinder heads, it’s best to consult with the manufacturer to determine how much milling can be done. Some aftermarket heads are made with extra deck material to accommodate future milling.

Remember, these specs apply to flat milling and are intended as general guidelines. Before you start milling, consult with a reputable machine shop that specializes in this type of work and follow their recommendations.

Do you have the formula for milling the Ford 427 and other FE heads???

Nice how they came up with the numbers on 6 different Fords but managed to leave out The F.E

[…] A: Depending on how much material is removed from your cylinder heads, you may need to cut or trim your intake manifold. Just recently we did a post on milling that covered this relationship between milled heads and the amount of material that needs to be removed from ther intake or block. You can review that Milling 101 post here. […]

How much to mill vortec 5.7 heads to a 5.0l sbc at .20 over bore,to meet 1999 stock fuel system.

I believe you’re missing a component that the amount to mill for proper intake alignment is for every 0.010” of material removed from the deck surface.

I would suggest to compare with other milling charts.

I have a Ford 1970 200 head c9de 6090 m

8.1 Cr

I would like too put it on my 65 200 l6 and keep my 9.1 cr .

My goal is to have smoother running motor after adding headers and s bit better performance daily driver, don’t want hot rod it. I’ve heard old steal shems .025 thick and new are .050. So I’d need too mill .025 for compensation of old gasket. After that not sure how much more.

[…] Resources: https://www.onallcylinders.com/2016/01/06/head-milling-101-the-basics-of-head-milling-to-gain-more-c… […]

PTJ Shop is Cnc Machining Expert has 12 years experience on custom non-standard parts. As a cnc machining factory We Material research & Design and manufacture products,Material types included aluminium,stainless steel,brass,copper,titanium,magnesium and plastic etc.,. our factory located in Dongguan, occupies an area Over 5,000 square meters.

Cnc Machining Online Quote Serviced aircraft&aerospace, automotive, LED lighting,bike,medical,electronic,mechanical,Oil&Energy and Military industries. Most of Our Customer business who base on Canada, Israel, Japan, Europe and USA, the business grow up year by year.

We are sincerely looking forward to your cooperation, warmly welcome you join us to share the market, and expand our business together!

Hi, I just purchased an engine and the owner advised that the engine block needs to be sceamed: Never heard of it. Is it possible, because usely the head of the engine needs sceaming and surely not ne block.

Please help me.

regards,

Francois

have a car that has had milled head and now CR has increased to by 100psi, not running properly any suggestions

Is there a typical limit to how much can be shaved before one runs into issues? For example, if I wanted to take some Viper V10 cylinder heads and shave them down to achieve a 14:1 static compression ratio, would that be possible? What type of issues might I run across. I can think of piston to valve clearance but are there any other limiting factors that may or may not come into play? If Viper head knowledge isn’t in your knowledge base then please use one that is for theoretical comparison. Thanks for any insight.

I have a GM 385 FastBurn with hot cam and 1.6 rockers.How much do I need to mill off heads to reach 10.5 compression.It is 9.6 compression oem.Will I need to mill intake also.Thanks.

Good info however I’m really just searching for how much metal can be removed without running into intake manifold gasket leaks? Some one long time ago told me .030 or less is safe … without issues… but I don’t know that to be a fact ….

[…] three sets of heads with different combustion chamber volume revealed a 6% horsepower increase. A cylinder head milling process involves removing material from the head or block deck surface, resulting in a lower volume of the […]

When angle milling. Do you remove same amount from intake side. SBC