I recently read a story in a national publication that struck me as interesting and worth dissecting.

The story tested the addition of a tall, long runner EFI intake manifold versus a production LS1 intake. I’ve recreated the curve in the charts and graphs included here. The test showed that the baseline combination using the stock LS1 intake made a respectable 512 horsepower at 6,800 rpm. That’s excellent horsepower for a production intake. The engine was fitted with aftermarket heads and a good hydraulic roller cam with 232/240 degrees of duration and 0.600-inch lift. The stock intake was removed and the taller, aftermarket intake and a larger throttle body were added. The subsequent testing revealed the taller intake was worth a solid 39 horsepower over the stock manifold, making an impressive 551 horsepower. None of this is earth-shaking news. We’ve seen this all before many times. It’s classic hot rodding.

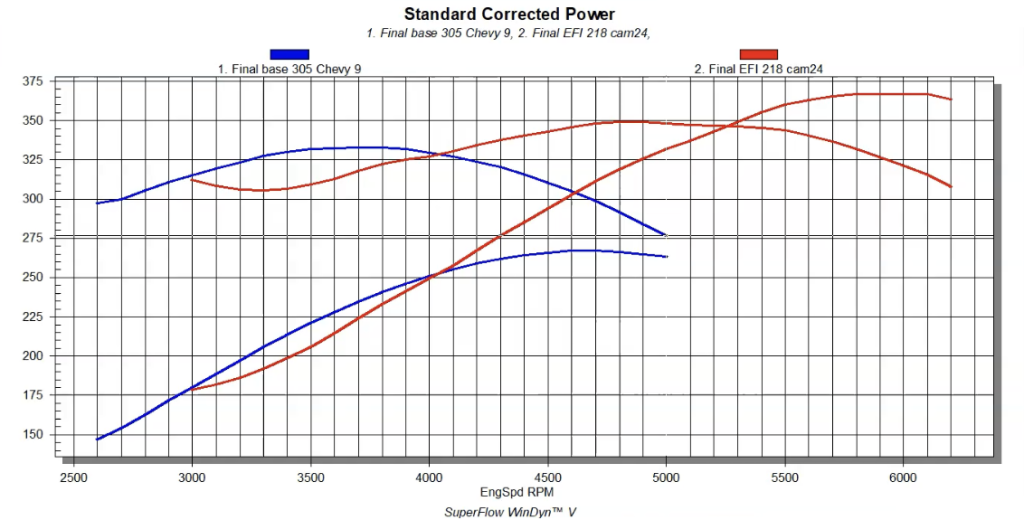

What caught my eye was the comparison of the two power curves. My experience with engine dyno testing is that often changes that create a horsepower increase do so by merely moving the power around. That is what happened with this particular test. In this example, the increase in peak horsepower came at the cost of mid-range torque. When I looked at the two torque curves, there was a significant sag in torque from 3,600 to 5,200 rpm.

A long time ago, my good friend the late John Lingenfelter told me that looking just at peak horsepower only tells a small part of the story. He said it’s much smarter to look at the entire power curve that the car uses. In this case, what power the tall manifold gained in peak horsepower, it more than gave up in terms of lost torque. Since torque is what accelerates the car, especially in the first one-eighth mile, it appeared to me that using this tall manifold on an average street car might not make the car any quicker–and might make it slower. Most enthusiasts might just look at the peak horsepower gain and instantly say without hesitation that the engine that makes the most peak horsepower would be quicker in the car. I’ve tested enough cars to know that isn’t always true. So I decided to test this idea.

The first thing I did was to compute the average torque of the entire rpm curve from 3,000 to 6,800 rpm for both the stock LS1 manifold and the tall aftermarket version. The average torque numbers instantly reinforced my suspicions. The stock manifold’s average torque was 420.5 ft.-lbs. per rpm point. The tall manifold’s average torque was 420.6 ft.-lbs. So the average torque was virtually the same.

One of my favorite computer programs is an excellent drag strip simulation program called Quarter Pro and Quarter, Jr. There are other good simulations tools as well like ProRacing Sim’s DeskTop Drag 5. I plugged the power curves from both tests into the Quarter Pro computer program using a simulated Camaro with a TH400 trans, 3,000 rpm stall speed converter, 26-inch tall tires, and a 3.73:1 rear gear. This represents a typical street car that might want to use that tall manifold. I entered both sets of torque curves into the program and the results were not surprising based on our average torque numbers. Here’s what the simulation delivered:

High Torque / Low HP Low Torque / High HP

| Drag Strip | High Torque / Low HP | Low Torque / High HP |

| 60-fooot | 1.69 | 1.69 |

| 330 – foot | 4.87 | 4.90 |

| 660- foot – 1/8th mile e.t. | 7.48 | 7.51 |

| ¼ mile e.t. | 11.64 | 11.69 |

| ¼ mile mph | 118.7 | 118.3 |

What this simulation comparison reveals is that the additional horsepower created by the tall manifold wasn’t enough to offset the lost midrange torque. Rather than just dismiss the manifold as poorly designed, let’s look at what’s really going on here. The car that we used to test this manifold is a typical street car using a three-speed automatic with a mild stall converter and mild gears. We then tried a four speed combination that would keep the engine speed up into the higher rpm range but even with this change, the lower horsepower combination was still quicker. We didn’t take this any further, but it is likely that a five-speed manual combination with reduced rpm drops between gears, the higher horsepower application would then be quicker.

It was not our intention to bash the aftermarket manifold because it does work as advertised. Instead, the attention should be focused on the consequences of intake tuning. In this particular case, moving the power curve up into a higher engine speed did improve peak power, but the loss of midrange torque cost more in terms of quarter-mile acceleration. Again, my buddy Lingenfelter told me the best engine modifications to make a car quicker were mods that would improve the power within the rpm where the engine spent most of its time. With typical street cars with street gears between 3.08:1 and 4.10:1, the engine spends much of its time around 4,500 rpm–which is close to peak torque for most street engines. So choosing an intake manifold, headers, carburetor, camshaft, or other component that helps improve torque in the midrange will have a much better chance of improving overall drag strip times. Assuming, of course, that you can hook the power to the ground and not spin the tires.

My agenda for this discussion was aimed at educating the reader on choosing the right parts for your application and not necessarily just buying the parts that make the most peak horsepower. And by the way, this also works for autocrossing and road race cars as well.

[…] Source: On All Cylinders […]

I have a question,

I’m doing mu first build every from ground up never done anything like this. . .

I bought a 84 c10 swb and a 94 short block 454 I was planning on putting it to a 700r4 and to a shortened wb dually axle . . . What are your recommendations for building the motor up for tow power plus hower power along wolith the rest of the drive train

Anthony, we bounced your question off the Summit Racing tech guys, and they have a few questions for you before they advise you on your build. Start by placing a call to them at 1-330-630-0240, and they’ll get you going in the right direction.

Hello to all, as I am genuinely eager of reading this weblog’s post to be updated daily.

It contains pleasant material.