440 cubic inches used to be the domain of rip-snorting big block engines. Even more specifically, the number 440 denoted the rip-snorting big blocks produced by Mother Mopar and the Pentastar Kids.

That was then, though. Thanks to the proliferation of high-quality factory and aftermarket blocks and stroker kits, you can build 440 cubes out of what used to be labeled small blocks. Many of those big-inch engines now wear bowties and blue ovals rather than pentastars–and thanks to fuel injection, CNC-ported heads, roller cams, and other modern wonderfulness–make horsepower that would send the big blocks of yore slinking home with their carburetors between their legs (if they had legs, that is).

To prove our point, we present this LS motor built by Trick Flow Specialties. It’s got it all going on—440 cubic inches, Trick Flow GenX™ 235 aluminum heads, Lunati/Diamond rotating assembly, .629-inch lift Lunati roller cam, F.A.S.T. EFI intake, and much more. All the parts are readily available items—and worth 680 horsepower on Trick Flow’s Superflow engine dyno.

Want to know more about this small block 440 powerhouse? Then read on, because Trick Flow allowed us to follow along and document the entire build.

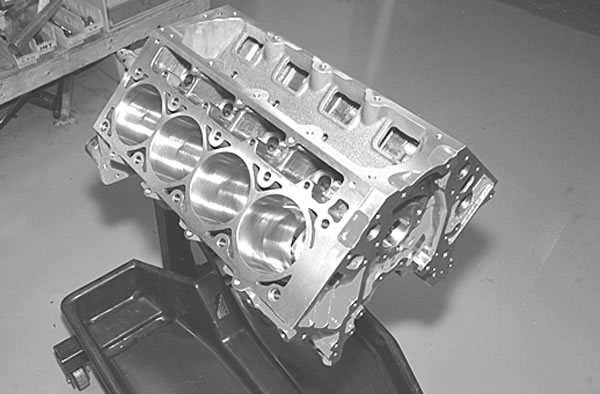

LSX Block

Based on GM Performance Parts’ LSX Bowtie block, the short block is designed for high-horsepower, large cubic-inch applications. The cast iron block comes with 3.990-inch semi-finished bores that can go out to 4.250 inches; combine that with a 4.500-inch stroke crank and you’ve got 482 cubic inches.

The LSX block also features the following goodies:

• Extra-thick siamesed cylinder bores

• Cross-bolted, ductile iron main bearing caps

• Windowed main bearing bulkhead—better crankcase breathing and windage control for improved high rpm power without reducing block strength

• True priority main oiling system—prevents oil starvation at main bearings, improves upper engine oil control

• Cylinder head decks can be machined to 9.200 inch height

• Six head bolt locations per cylinder bore for better head and gasket retention with high

compression or forced induction

• Rear oil feed line for use with dry sump oiling system

• Cam bores can be machined for 60mm diameter roller cam bearings

• Screw-in freeze plugs at front and rear of block can be removed for use with engine heaters or coolers

• Motor plate mounting bosses on the front of the block for drag and circle track racing

applications

• Additional (7th) transmission mounting bolt hole to accommodate early (pre-LS) GM

transmission mounting pattern

The LSX block accepts most regular LS-spec parts, including cranks, pistons and rods, camshafts, cylinder heads, valvetrain, oiling system components, and external stuff like motor mounts—no need to pony up for expensive “race-only” parts. Unless you want to, of course.

Crank, Rods, and Pistons

Building 440 cubic inches with an LSX block requires 4.125-inch bores and a 4.125-inch stroke. Lunati provided the stroke in the form of a Pro-Series crankshaft. The crank is whittled from 4340 steel alloy and features cross-drilled mains for improved oiling, 7/8-inch lightening holes in the #2, #3, and #4 rod journals, and .140-inch radii on rod and main journals to reduce chances of fatigue cracking. Lunati also supplied the 6.125-inch I-beam rods; they’re also 4340 steel forgings that come weight-matched (+/-1.5 grams) and have ARP cap bolts.

The pistons were sourced from Diamond Racing. The forged slugs come with a ceramic thermal barrier coating to reflect heat back into the combustion chamber where it belongs, and a dry film moly coating on the skirts to reduce friction. The pistons have a -10.6cc dish that yields a 10.8:1 compression ratio with the 70cc combustion chambers in the Trick Flow GenX Street/Strip 235 cylinder heads.

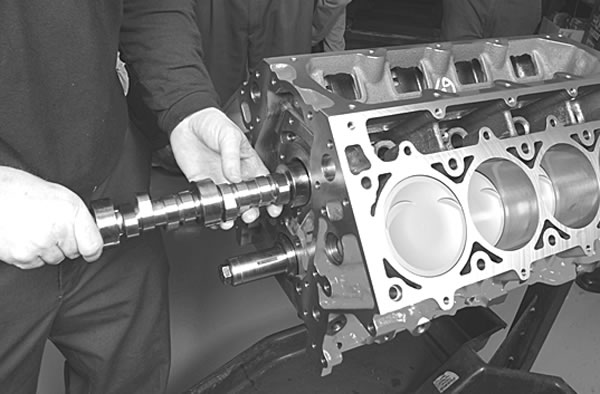

Camshaft

It was Lunati to the rescue again when it came to the bumpstick. It supplied a healthy hydraulic roller, custom-ground for the 440. It features 262-degree intake/270-degree exhaust duration @ .050 and .629 inches of valve lift with a 1.7-ratio rocker.

Odds and Ends

Other parts Trick Flow used to complete the LSX short block include:

- Comp Cams adjustable timing chain set

- Clevite H-series main and rod bearings with TriArmor moly/graphite coating

- ARP main stud kit

- Fel-Pro gasket set, GM Performance Parts head gaskets

What’s cool about building an LSX short block—or any LS-based engine, for that matter—is how simple it is to assemble. At the fundamental level, an LS is just a pushrod 90-degree V8; if you’ve built a small block Chevy, you can build one of these. Check out the slide show below, and we’ll show you how the short block came together. We’ll look at the top-end in part two of the build.

[…] showed you how Trick Flow Specialties built a GM 440 LSX in an earlier post—now check out the slide show gallery to see how the Mopar guys assemble 440 […]

[…] Specialties was in the process of building the short block for its 440 cubic inch GM LSX engine (440 LSX, Part 1). Designed for LS development work on Trick Flow’s Superflow dyno, the short block was built heck […]

juny, chekeate esto.