This article comes to us from our pals over at Mahle Motorsport. For decades, the Mahle folks have supplied performance builders with precision pistons, rods, rings, and more—so when they start talking about engine internals, we’re inclined to listen. Today, we’re learning all about the importance of the surface finish on your cylinder walls.

***

When building or refreshing an engine, enthusiasts often focus on pistons, rods, crankshafts, camshafts, and cylinder heads.

While these components are critical, one area that doesn’t always get the attention it deserves is the cylinder wall finish. The way a cylinder is honed has a direct impact on piston ring seal, engine break in, and long-term wear characteristics.

Why Cylinder Wall Finish Matters

The cylinder wall is the running surface for the piston rings. It must provide enough texture to hold oil for lubrication yet be smooth enough to allow the rings to seat quickly and maintain an effective seal. Too rough, and the rings may wear prematurely or never achieve full seal. Too smooth, and the rings may skate across the surface, resulting in blow-by and oil consumption.

Striking the right balance is both an art and a science.

Ring Seal and Performance

Piston rings are asked to handle multiple tasks in an engine, and the cylinder surface plays a direct role in how effectively rings can do their job:

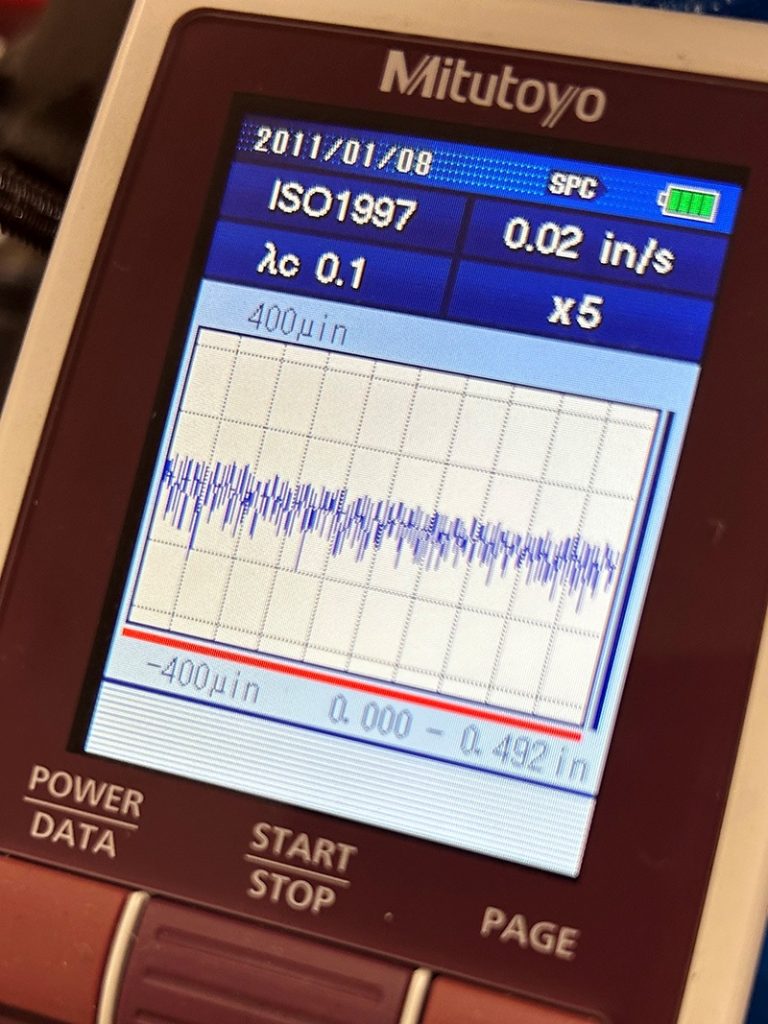

- Proper crosshatch angle (typically between 40° and 50°) ensures oil is evenly distributed and prevents pooling or starvation.

- Surface roughness (Ra, Rz, and Rpk/Rvk values) proper finish reduces break in time by minimizing the amount of wear on cylinder and ring before parts are bedded.

A correctly honed surface maximizes combustion efficiency and minimizes blow-by, directly translating to more power and durability.

Engine Break-In

The initial break-in is the most crucial period for establishing a proper wear pattern between the piston rings and cylinder wall.

- If the finish is too rough, your rings may wear excessively, producing wear particles that contaminate the oil.

- If the finish is too smooth, the rings may glaze over the surface instead of bedding in, preventing them from ever fully sealing.

A properly honed cylinder ensures the engine breaks in quickly and cleanly, avoiding premature wear and setting the stage for long service life.

Wear Characteristics & Longevity

Cylinder finish doesn’t just matter during assembly and break-in—it influences how the engine wears over time. A surface that retains the right amount of oil prevents dry spots and reduces friction, extending both ring and bore life.

Make Sure Your Engine Build Goes Smoothly

Cylinder finish is one of those behind-the-scenes details that makes or breaks an engine build. Precision in this area ensures that the investment in high-quality pistons, rings, and other components pays off with maximum performance, efficiency, and longevity.

Whether you’re building for the track or the street, never overlook the surface your rings ride on—because the best pistons and rings in the world can’t do their job without the right cylinder finish.

Comments