The popularity of the GM LS engine is undeniable. When Ford guys are stuffing LS engines into Fox body Mustangs, you know that this engine has gone viral. The fact that engine builders routinely push production LS engines past 2,000 horsepower with the help of power adders is a testament to the engine’s durability. The original LS engine was designed around an aluminum block—which is why the iron version can survive such high-powered antics.

But there are limitations.

That’s what the engineers at Blueprint Engines (BPE) decided to address with this latest version of the LS engine block. You may recall that BPE first introduced their version of the small block Chevy in 2024 using a brand new casting from a foundry in Germany.

They took this same approach for the LS.

Yes, this new block is stronger with help from a higher grade of Class 35 iron alloy. It’s the combination of priority main lubrication, thicker cylinder walls, engineered space for longer strokes, and accurate CNC machining that really addresses the needs of so many high output LS engine builders.

Click here to see pricing & availability of the Summit Racing/BluePrint Engines SPC LS engine blocks.

We’ll start with some basics and then get into the dozens of details that are so important for engine builders. This new iron block from BPE and Summit Racing incorporates multiple improvements but perhaps the most important is the addition of priority main oiling.

Production LS blocks feed the hydraulic lifters first and then push the oil to the main journals on the crankshaft. The Summit Racing/BPE block adds a third main oil gallery that pushes oil first to the crankshaft while simultaneously also feeding the lifters.

Despite the changes, this new block retains nearly all of the original equipment LS configurations such as its 4.400 inch bore spacing, oil pan, front and rear covers, the stock 4-bolt head bolt pattern, as well as the bellhousing and engine mount patterns. The one addition that is high on the high horsepower list is the two additional head bolts for each cylinder for a total of six.

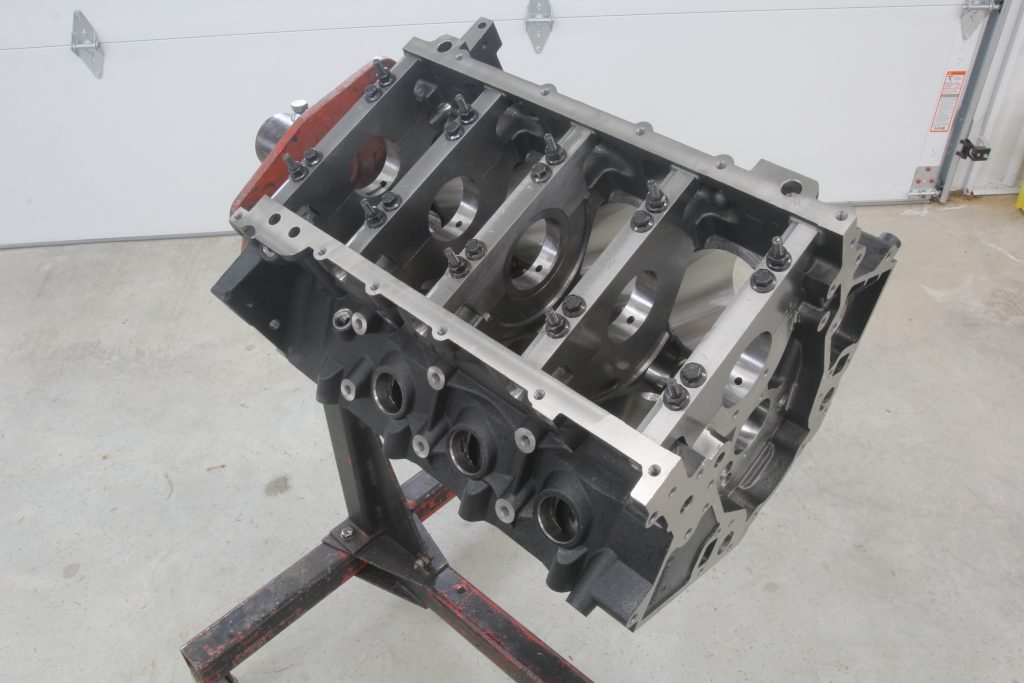

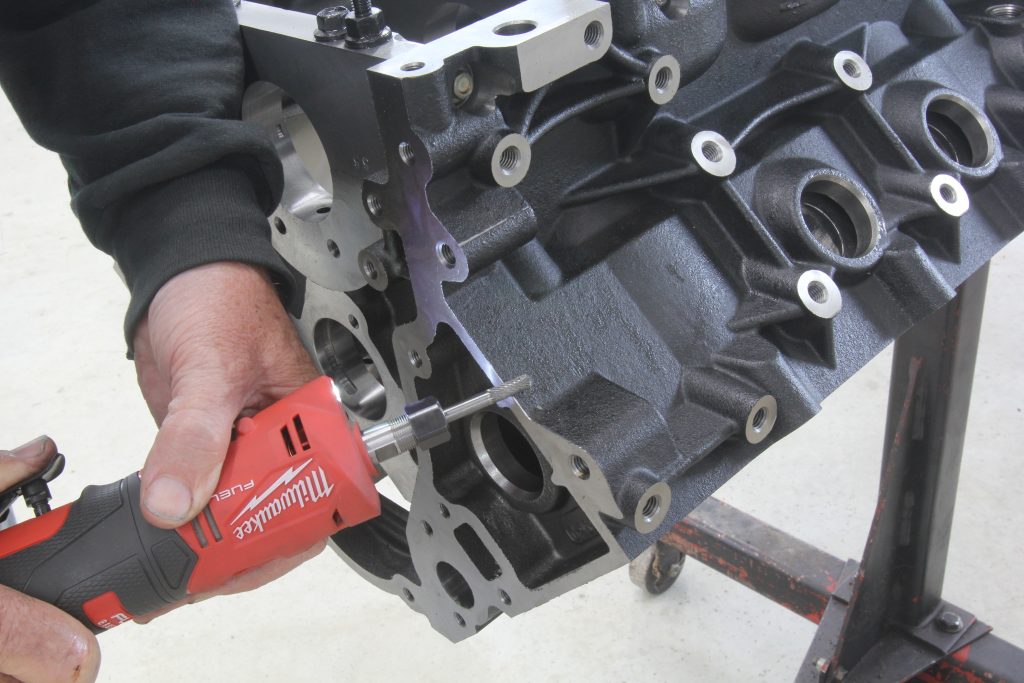

Moving to the crankcase area, the deep skirt orientation retains the production style cross-bolted main caps but with some changes. The main caps are now billet steel as opposed to iron while retaining the stock 10mm main bolts and smaller 8mm cross bolts.

The iron block LS crowd will rejoice in the changes made to the deep skirt area where the block is relieved to allow up to a 4.250 inch stroke. You can see evidence of this externally with the slight bulges on the outside of the block just above the pan rail. The main cap area is also machined to enhance breathing between the paired cylinders front to back on the engine.

When the talk focuses on adding stroke, the easiest way to accommodate a longer stroke is by adding height to the block. This first iteration of the Summit Racing/BluePrint Engines block will feature both a standard deck height which is the same as production at 9.245 inch as well as a tall deck version that measures 9.705 inches. Both of these blocks position the cam centerline in the stock location.

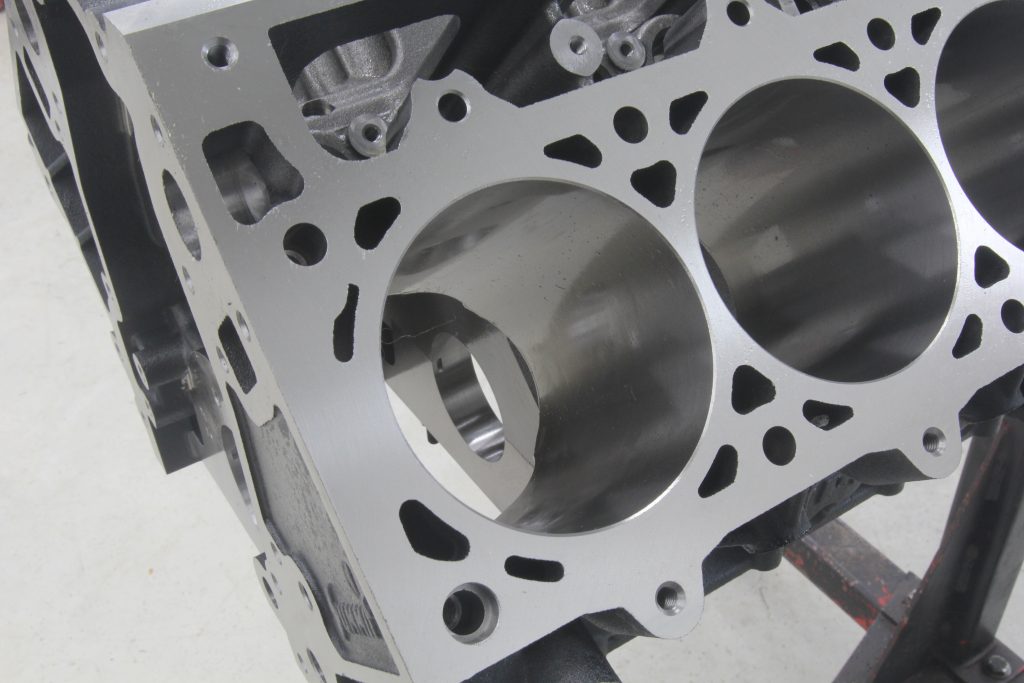

What is less well known or appreciated regarding stroker applications is that the OE LS block limits stroke not by clearances around the oil pan rail but actually because of cylinder sleeve length. This is the overall length of the cylinder measured from the bottom of the cylinder to the deck surface. Stock LS blocks measure 5.500 inches, which is somewhat short.

The problem with adding stroke is that the piston now travels farther down in the bore to create this additional piston travel. This can create a situation where the bottom of the piston skirt exits the bottom of the cylinder sleeve and then can tilt or cock, which will immediately damage the piston skirt and that cylinder..

The standard deck height Summit Racing/BPE SPC block cylinder sleeve length is extended an additional 0.250-inch for a total of 5.750-inches which should be more than enough to accommodate even the 4.250-inch stroke versions assuming the pistons are designed correctly Summit is working on crank, rod and piston assemblies that will be designed around this new block to take advantage of this feature.

The lower portion of the block also exhibits more interesting changes as BPE added a total of nine freeze plugs to the block. But even with these additions, the block retains the stock Gen. III/IV four-bolt motor mount position and spacing. The crank sensor is also retained in the stock location. This block must be considered a Gen. IV block because the original Gen. III cam sensor location at the back of the block has been eliminated. This moves the cam sensor to the front timing cover which will require a Gen. IV front cover and cam sensor.

For obvious reasons, the design engineers also eliminated any of the need for the Gen. IV AFM or Active Fuel Management cast-in towers in the lifter valley. This allows room for a more substantial PCV valve breather which was used in prior Gen. III configurations.

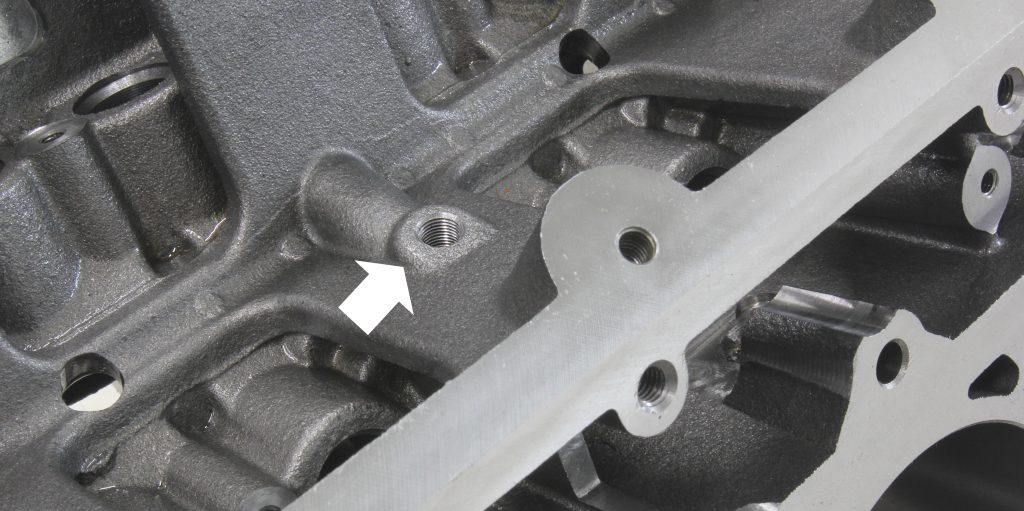

Also in the lifer valley is a single 1/8 inch threaded pipe thread hole that was included to give production access to a drill hole for the oiling system. This hole will need to be plugged to prevent a massive internal oil leak. While the block did add a priority main oil gallery, the oiling system is still configured around the stock LS orientation including the need for the stock type diverter valve found at the rear of the block as well as that small pressed-in plug at the front of the main oil gallery.

Moving upward, it’s obvious this block is intended for high output use because the engineers also included a 6-bolt head pattern in the deck. This places two additional head bolt holes in the deck at the top and bottom of each cylinder to add clamp force. Of course, since the head bolt holes are blind, meaning they are not drilled through to the cooling system, that you can still use a stock four-bolt head on this block with no issues.

The deck surface is also reinforced to 0.625 inch that does much to help retain the head gasket in place when subjected to high cylinder pressure applications. Summit Racing says that this block can easily withstand 2,500 horsepower without complaint.

We’ve included a chart with this story that details most of the popular bore and stroke combinations for this new block. Everyone always wants to know the biggest displacement you can push this block to so combining the 4.185 inch maximum bore with a 4.250 inch stroke the chart shows an impressive 468 cubic inches. But on the slightly more conservative side there are also 4.000 inch and 4.125inch cranks currently on the market from companies like Callies, Eagle, Scat, Summit and others. Among the more interesting intermediate cubic inch combinations might be a 441ci package with a 4.125 inch bore and stroke.

While at our deadline we don’t have specific numbers from our friends at Straub Technologies, they have tested the BPE / Summit small-block Chevy block for machining accuracy. BPE and Summit Racing’s numbers place the deck height at exactly the 9.240 inch number, with a possibility it could be as much as 0.005 inch taller. The main bearing housings are generally right in the middle of the GM spec which makes setting bearing clearances a bit easier.

In evaluating the small block Chevy block, Straub found the lifter bores were also extremely close to the GM original blueprints so there is every expectation that this new LS block will test with very nearly the same accuracy. Straub’s comment on the small block BPE block was that he had never tested a small-block block that came as close to the design specs as this Summit Racing/BPE block. This is the result of good German castings and accurate CNC machining.

This is what you can expect from this new Summit Racing/BPE block. Combine a high quality block with priority main, 6-bolt cylinder head capability, and excellent machine work with a quality casting with billet main cap an you have all the ingredients for a winning big-inch engine.

Click here to see all the blocks in the Summit Racing SPC engine block family.

Summit Racing SPC Engine Block Bore/Stroke Combinations

This chart offers multiple bore and stroke combinations that could be applied to this new Summit Racing/BluePrint Engines SPC LS block. For the sake of accuracy, this chart uses finished bore sizes and a standard deck height.| Displacement (Cubic Inches) | Bore (Inches) | Stroke (Inches) |

|---|---|---|

| 376 | 4.065 | 3.620 |

| 405 | 4.065 | 3.900 |

| 415 | 4.065 | 4.000 |

| 428 | 4.065 | 4.125 |

| 387 | 4.125 | 3.620 |

| 417 | 4.125 | 3.900 |

| 427 | 4.125 | 4.000 |

| 441 | 4.125 | 4.125 |

| 454 | 4.125 | 4.250 |

| 392 | 4.155 | 3.620 |

| 423 | 4.155 | 3.900 |

| 434 | 4.155 | 4.000 |

| 447 | 4.155 | 4.125 |

| 461 | 4.155 | 4.250 |

| 398 | 4.185 | 3.620 |

| 429 | 4.185 | 3.900 |

| 440 | 4.185 | 4.000 |

| 454 | 4.185 | 4.125 |

| 468 | 4.185 | 4.250 |

Summit Racing/BluePrint Engines SPC LS Engine Block Specs

All specs in inches unless otherwise noted.| Description | Spec |

|---|---|

| Origin | Block cast in Germany, machined in the USA |

| Block Material | Class 35 Iron Alloy, 250 MPa tensile strength |

| Block Weight | 232 to 247 lbs., given bore and deck height |

| Bore Size, Unfinished | 4.060 or 4.120, requires final hone |

| Bore Spacing | 4.400 |

| Maximum Bore Size | 4.185 |

| Min. Cylinder Wall Thickness | 0.170 at maximum 4.185 bore size |

| Cylinder Sleeve Length | Std. deck 5.750, tall deck 6.210 |

| Deck Height | 9.245 or 9.705 (+0.005 to -0.000) |

| Lubrication System | Priority main |

| Deck Thickness | 0.625 |

| Cylinder Head Bolt Holes | Blind |

| Head Bolt Size | M11 x 2.0 |

| Main Bearing Housing Bore | 2.7509 – 2.7514 |

| Main Cap Bolts | M10 x 2.0 |

| Main Cap Material | Billet steel |

| Clearance for 4.250 In. Stroke | Yes |

| Cam Location | Stock |

| Lifter Bore Size | 8.437 +/- 0.0005 |

| Cam Bearing Bore Size | Stock Gen. IV 3rd design, all 5 same dia. |

| Cam Drive | Accepts OE LS timing chain set |

| OE Hyd. Roller Lifter Provision | Yes |

| Oil Pump | OE location & operation |

| Oil Pan Rails | Solid (no water jackets) |

| Accepts Stock LS Oil Pan | Yes |

| Dipstick | Passenger side of block |

| Water Jackets | Expanded slightly for additional cooling |

| Freeze Plugs | 1-5/8 dia., 9 required |

| Crank Sensor | OE location, accepts 24x or 58x |

| Oil Plugs | 9-3/8 |

| Coolant Plugs | 2-1/4 |

| Lifter Valley Plugs | 1-1/8 NPT |

Parts List

- Summit Racing SPC LS iron block, 4.060, std. deck – SUM-150215

- Summit Racing SPC LS iron block, 4.120, std. deck – SUM-150216

- Summit Racing SPC LS iron block, 4.120, tall deck – SUM-150217

- Summit Racing LS cam bearings – SUM-1002S00

- Clevite cam bearings – CLE-SH2125S

- Dura-Bond cam bearings, Gen. IV – DUR-CH25

- ARP head bolts, Gen. IV, 8740 – ARP-134-3610

- ARP head studs, Gen. IV, 8740 – ARP-234-4317

- ARP main studs, Gen. III – ARP-234-5608

- Summit Racing LS barbell kit – SUM-120-116

- Melling oil galley diverter barbell – MEL-MOGP-100

- Dura-Bond front galley plug – DUR-AP-023-P

- ACDelco front timing cover, Gen. IV – ADO-12600326

- Dorman rear main seal cover – RNB-635-518

you could do a couple old school motors. bore 4.8 out to 3.840, with a 3.26 crank, you get 302 cu. in. next ,put a 3.26 crank into a 6.0, and you get 327 cu.in. just sayin.

Old man’s dream always wanted a 302 Summit raising is another better how much would it run a guy?