Crate motors are awesome, so let’s find out how to make it awesome(r)!

Right off the bat, having a complete, crate motor show up at your doorstep provides not only an established power output, but also time savings. In the case of this 6.2L LS3 from BluePrint Engines, the crate motor even featured a serious warranty, something unusual for such a performance motor.

As much as we liked all of these attributes, we couldn’t help ourselves and began to wonder how well the original crate engine might respond to a few simple modifications. We know this breaks the cardinal rule of crate engines, as it alters the established power output element, but we view any motor as simply a starting point, a blank canvas if you will.

As good as the BluePrint LS3 was in stock trim, we figured we could make it even better with the right combinations of modifications. Besides, people are different, and so too are their definitions of the ultimate power plant. For some, it’s the efficiency of EFI, but for others, there is no school like the old school. Just because the OEMs have replaced cantankerous carburetors with modern fuel injection doesn’t mean they didn’t work for decades, and continue to do so.

For you O.G. carb folks, we decided to carb this crate!

In truth, we had ulterior motives for our induction upgrade, as the carburetor was definitely not the whole story.

After all, why make a modification when you can make a MODIFICATION! (You know things are getting serious when we resort to all caps!)

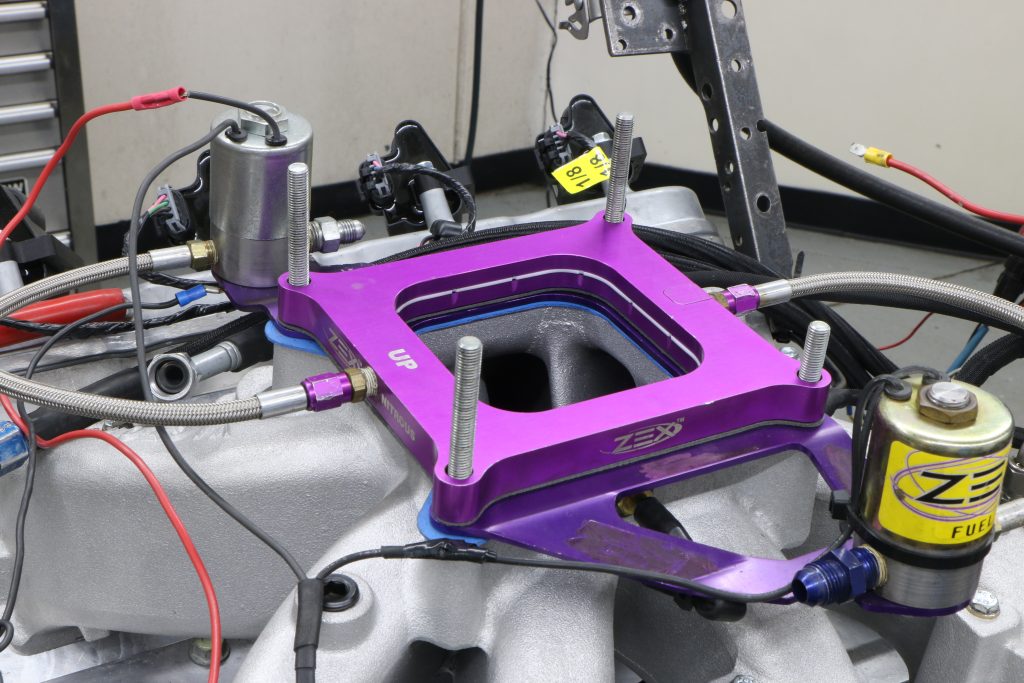

Text puns aside, the reason for the oversized lettering is that there are minor modifications and then there are major ones. The differentiation between the two is the potential power gain. The carbureted induction system will definitely improve power, or at least peak power output of the crate motor, but the gains offered by the alternative induction pale in comparison to what we sandwiched between the carburetor and intake. You see fellow fanatics, the carbureted intake was merely the enabler for our Zex Nitrous system.

As much as we liked the simplicity and power potential of the carburetor, it was the veritable babbling brook of power compared to the rushing river offered by the nitrous kit. Sure, we could have (and did) run nitrous on the EFI motor, but why make a small change when there is an opportunity to go big? Carb engines need love too, and nothing goes better with a mechanical mixer than some chemical chaos.

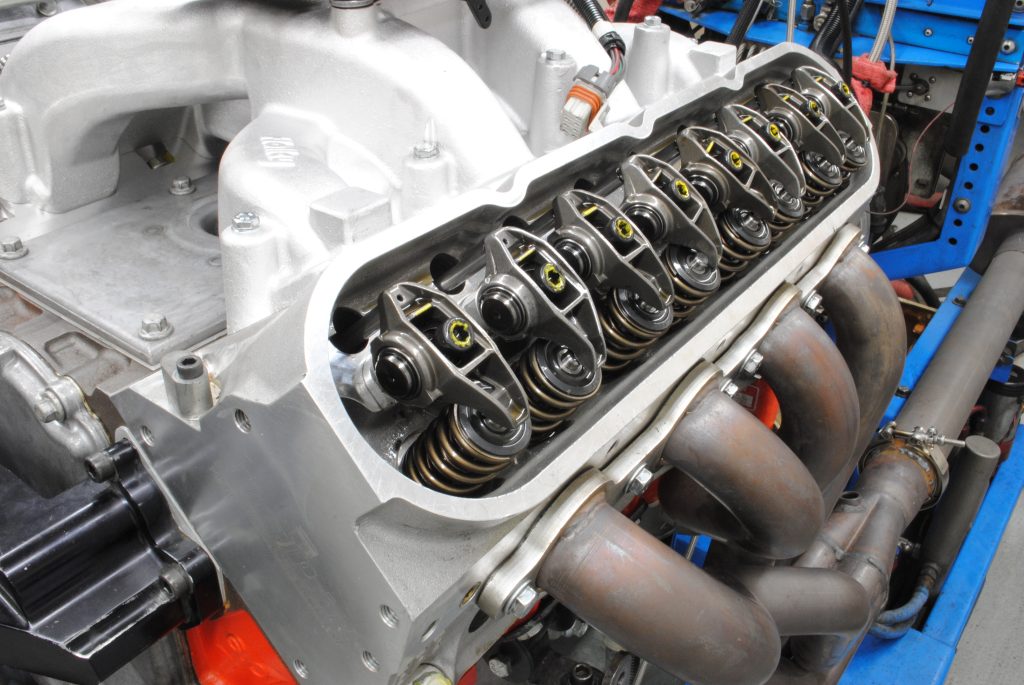

For those of you just joining the party, our test motor was a LS3 crate motor supplied by BluePrint Engines (BPE). The BPE LS3 featured a GM LS3 block combined with a nodular-iron crank, powdered-metal rods and hypereutectic pistons. The LS3 short block was topped with a set of BluePrint’s own LS3 head castings. The BPE LS3 heads featured a 259-cc intake ports, a 2.165/1.6 valve combo and 72-cc combustion chambers.

The one upgrade made previously to the crate LS3 motor was to upgrade the supplied cam with a unit from Brian Tooley Racing. The BTR Red Hot cam offered a 0.619/0.617 lift spring, a 221/24X degree duration split and 113 degree LSA. The cam was accompanied by a set of dual springs from BTR.

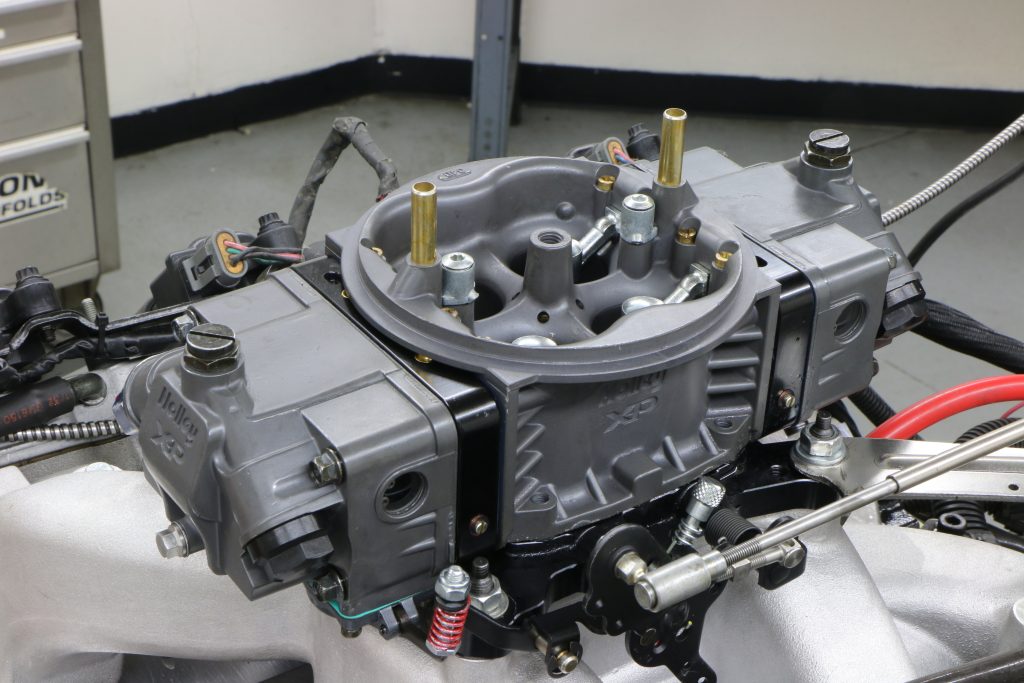

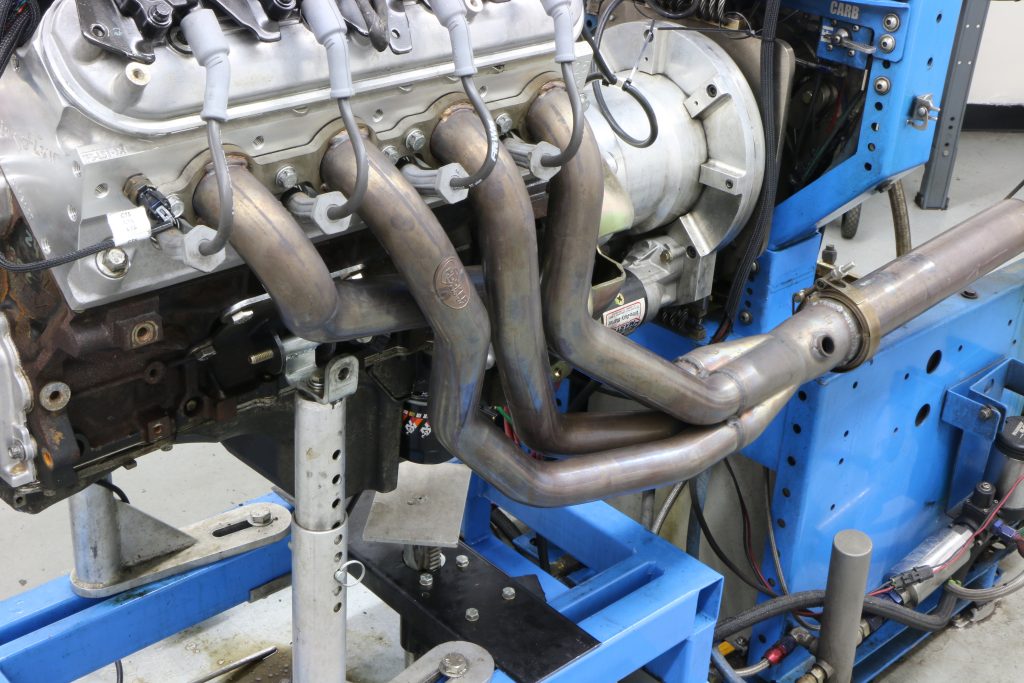

The BPE crate motor was originally supplied with not only a complete LS3 induction system, including GM intake, DBW throttle body and injectors, but also mechanical water pump and coil packs. To prep for this test, we removed the EFI system and replaced the stock LS3 components with a carbureted induction system that included a single-plane, Edelbrock Victor Jr. manifold, and 850 CFM Holley Ultra XP carburetor. Finishing things up was an MSD ignition controller, 1-7/8 headers and 91-octane pump gas.

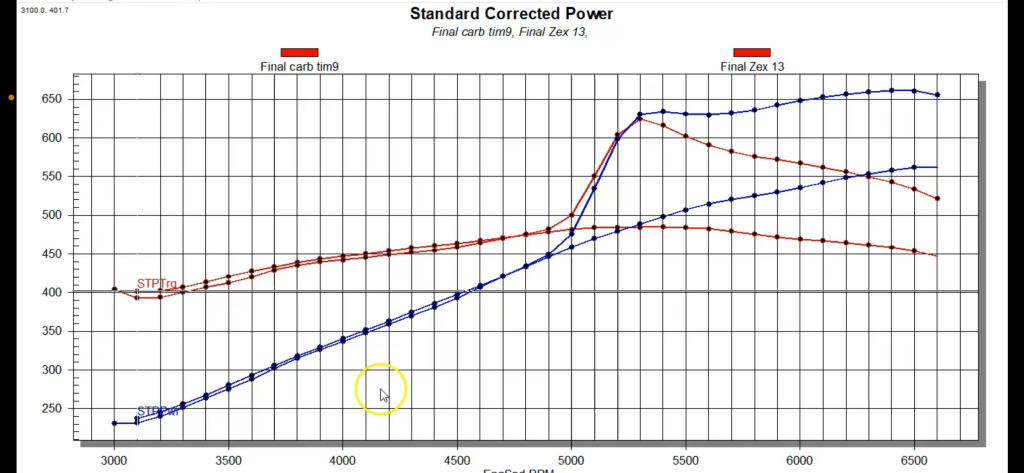

Run with the carburetor, the BTR-cammed LS3 crate motor produced 562 hp at 6,600 rpm and 485 lb.-ft. of torque at 5,400 rpm.

With the new induction system in place, it was now time for some nitrous.

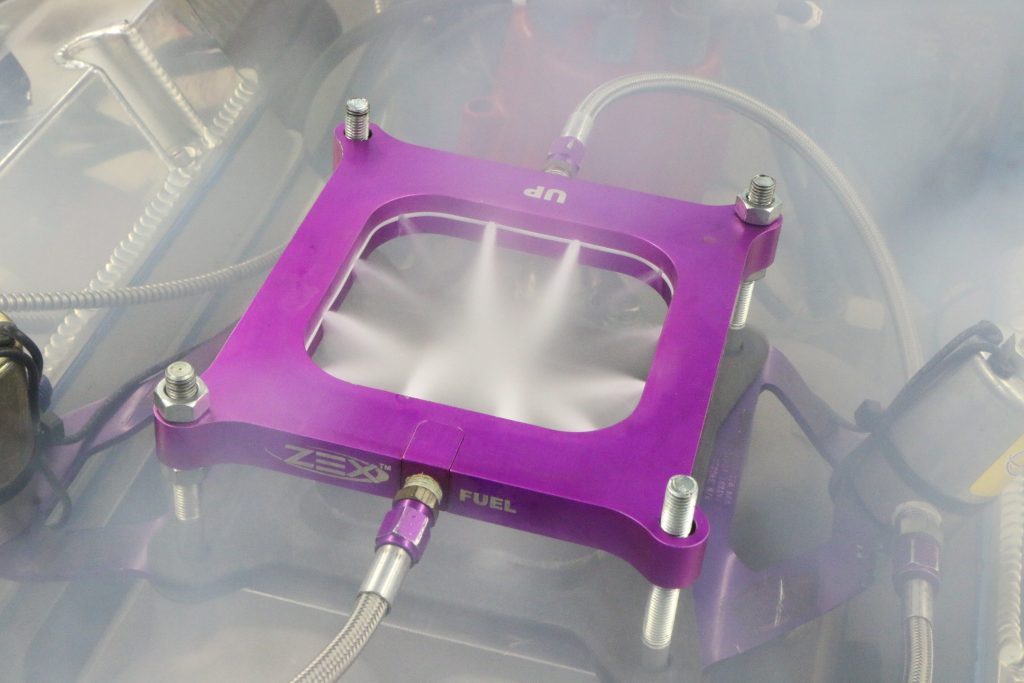

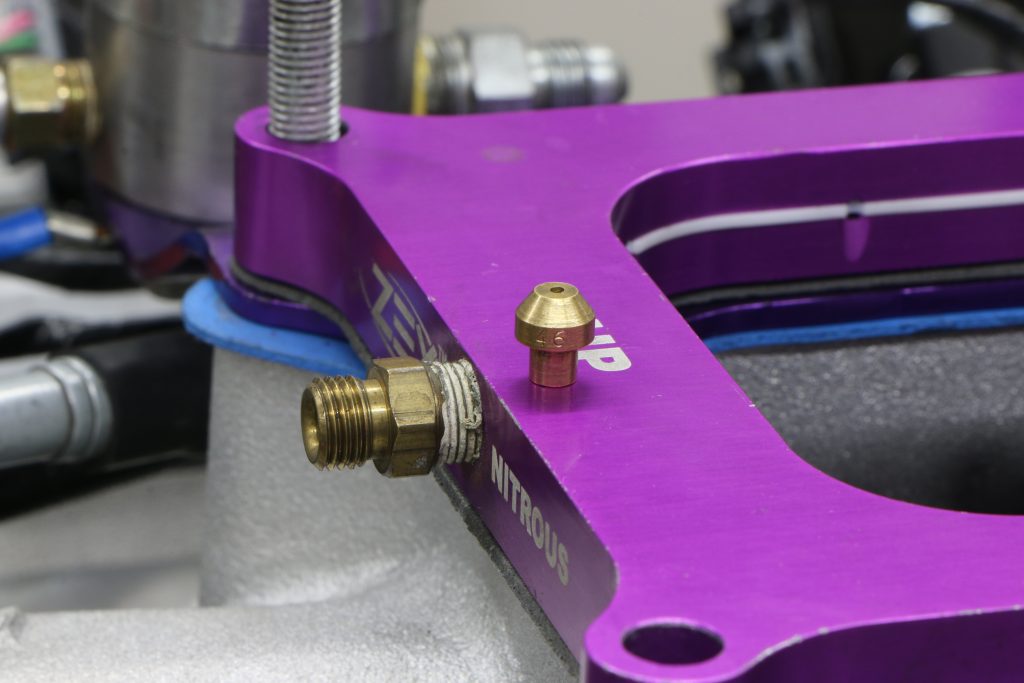

Because we had no intention of going crazy with the nitrous power level, we purposely chose the affordable and simple Zex Perimeter Plate nitrous kit. The Zex kit was an easy-to-install carbureted plate system. Like most systems, the power output of the Zex nitrous kit was adjustable using the supplied jetting. We chose a simple 100 hp shot for our crate motor, and installed the plate nitrous between the carburetor and intake using the supplied carb studs.

Prior to running, we made sure to fill and heat the nitrous bottle to ensure proper bottle pressure, then adjusted the fuel pressure supply to the fuel solenoid to six psi. Per the instructions, we then retarded the total ignition timing under boost by four degrees. With our bottle and fuel pressure optimized, we once again ran our carbureted crate motor in anger.

After activation of the nitrous, the power output jumped by a solid 100 hp, with peak numbers of 661 hp and 624 lb.-ft. of torque. We made only one pull with the nitrous, but it is hard to how easy it was to add another 100 hp to the carbureted crate motor.

Comments