If you’re new to nitrous oxide and are thinking about getting power from a bottle, this guide is for you. We’ll cover the basics of using nitrous in a straightforward manner, avoiding the complex setups typically used by experienced racers and tuners. In this article, we will explain how nitrous works in simple terms and provide a clear outline for the average enthusiast considering adding the “juice” for more power.

Safety & Storage

Nitrous oxide systems can be installed quickly and provide more horsepower per dollar than any other performance modification. Contrary to the exaggerated depictions in movies, nitrous oxide is not flammable; rather, it is a strong oxidizer that supports and accelerates the combustion of fuels like gasoline. However, it is essential to follow safety guidelines when handling nitrous and bottles.

First and foremost, avoid leaving filled nitrous bottles in direct sunlight, especially if they are unsecured. Doing so can cause the pressure inside the bottle to rise to dangerous levels—up to 3,000 psi—possibly rupturing the safety disc that’s mounted in the valve assembly. When this occurs, the bottle can become a small rocket. It is crucial (and an NHRA/IHRA requirement) to use a blow-down tube or hose attached to a bulkhead to channel nitrous outside the vehicle in case of a safety disc rupture and to secure the bottle properly inside the vehicle. Be sure to take the same care when storing nitrous bottles in your home, garage, or trailer. The combination of an unsecured bottle and blown safety disc has done serious damage.

There’s no reason to fear using or working around nitrous oxide. Simply use common sense and read all the instructions before installation or operation. If you’re overwhelmed, seek out the help of a local pro.

How Nitrous Builds Power

Now that we’ve covered the basics of bottle safety, let’s move on to a more exciting topic: how nitrous oxide enhances engine power. Nitrous oxide works by injecting a high concentration of oxygen into the intake charge, a process often referred to as chemical supercharging. The increased oxygen level, combined with the additional fuel needed, creates a more powerful combustion reaction. This results in higher cylinder pressure and, ultimately, more horsepower. Additionally, when nitrous oxide transitions from a liquid to a gas at the injection point, it absorbs heat from the surrounding air and provides a cooling effect.

Nitrous is stored as a liquid in nitrous oxide bottles, which vary in size from several ounces (commonly used for motorcycles) up to 20 pounds, with 10-pound bottles being the most common. The duration of use for a 10-pound bottle depends on the power setting. For instance, if you use a 100-horsepower “shot,” the approximate consumption is 0.8 pounds of nitrous every 10 seconds; this means that a 10-pound bottle could last for about 12 to 13 ten-second-long shots at the 100-horsepower level.

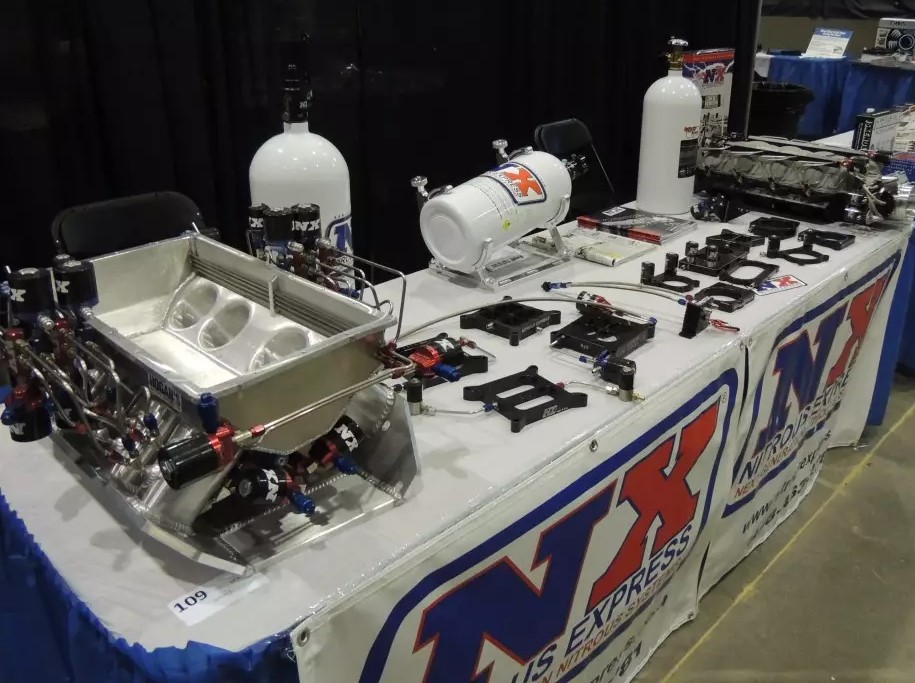

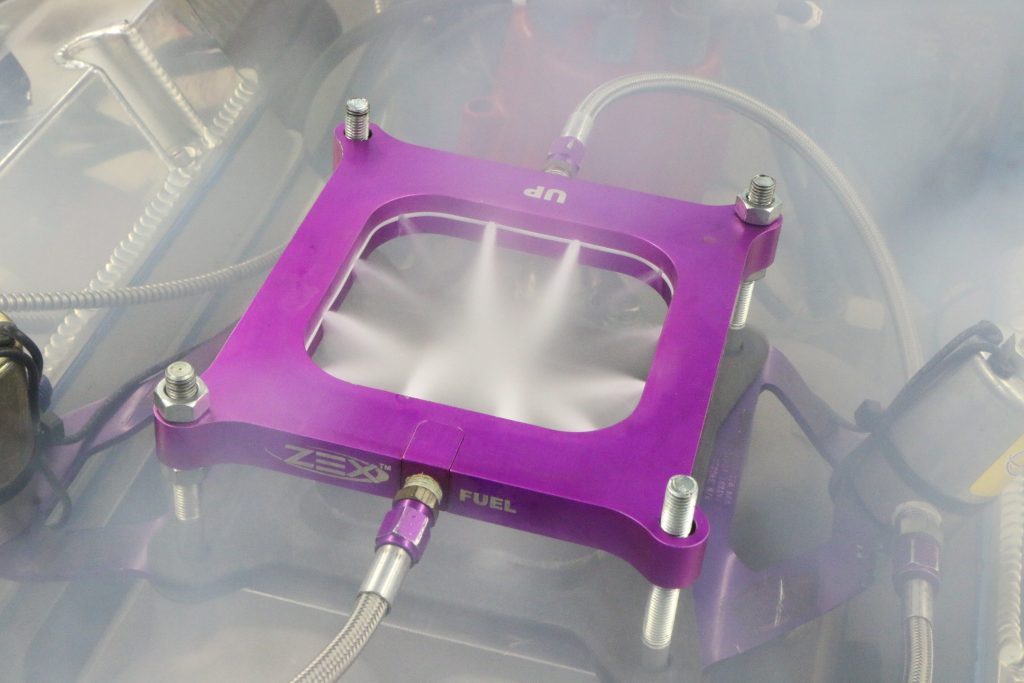

There are several methods to inject nitrous into an engine, depending on the type of induction (carburetor or EFI), intended use, and desired power output. Many kits use a plate that is installed between the carburetor or throttle body and the intake manifold. Another option is to inject nitrous directly into an intake tube or into each intake port using individual nozzles.

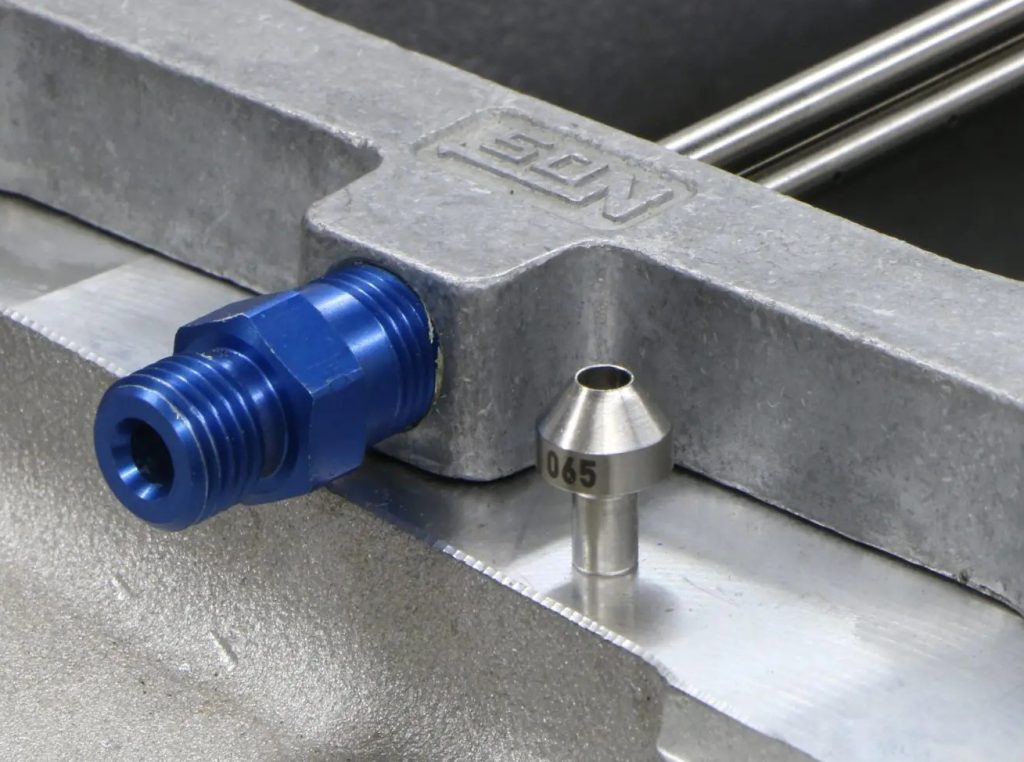

The amount of nitrous injected is determined by jet sizes, similar to carburetor jetting. Solenoids also play a role, and they are available with different flow ratings to meet specific needs. When kits specify a maximum horsepower range, it is not just about the included jet sizes; it also takes into account solenoid flow rates and the size of the plate or nozzles.

Prepping for More Power

When assessing a nitrous system, start by determining how much power you want to add. Then, explore the available options at SummitRacing.com that fit your specific application, keeping in mind that most kits are universal. It’s also crucial to consider the power levels your engine can safely handle. Most stock V8 engines can accommodate an additional 150 horsepower, while 4- and 6-cylinder engines can typically withstand an extra 50 to 100 horsepower without any internal modifications. If an engine has been upgraded internally with a stronger rotating assembly, it can handle more power. Regardless of your setup, achieving additional power from nitrous depends on proper tuning and installation. Always follow the manufacturer’s instructions and don’t hesitate to ask questions if needed.

Since nitrous oxide allows the engine to consume more fuel, a larger fuel pump may be required. If the fuel system cannot maintain the appropriate volume and pressure while using nitrous oxide, the engine may run lean, which could potentially cause serious damage. To prevent catastrophic engine failure, a fuel pressure safety switch, which automatically shuts off the nitrous system if the fuel pressure drops below a safe level, is recommended.

Some installers prefer to use a dedicated fuel system for wet nitrous applications (as described below), keeping it separate from the engine’s main fuel system. This approach enables the independent adjustment of fuel pressure and ensures consistent fuel flow without diverting supply from the primary fuel system.

Types of Nitrous Systems

There are two main styles of nitrous systems: wet and dry. These can be further subdivided into on/off, progressive, and multistage systems.

Wet systems inject atomized fuel alongside nitrous, using a solenoid for each component.

In contrast, dry systems inject nitrous alone, only using a nitrous solenoid, while the fuel injectors provide the additional fuel needed when the nitrous is activated. This type of system is often used in conjunction with programmable engine management that includes a nitrous reference input, which increases the injector pulse width when nitrous is activated. Depending on the amount of nitrous added, larger fuel injectors may be necessary. Another option would be to use a standalone or dedicated fuel enrichment system.

On/Off systems function in a straightforward way—either they are completely engaged or completely disengaged. This is the standard operating mode for most nitrous kits, which usually include an arming switch, a microswitch connected to the throttle for wide-open throttle (WOT) activation, and a manual activation button. However, there are additional factors to consider beyond what the basic kit offers. It is essential to activate the nitrous under the appropriate conditions to avoid backfires or potential engine damage. Ideally, nitrous should be activated when the engine is under full load and operating within its powerband.

Progressive systems vary the flow based on rpm and/or time by modulating solenoid pulse width. This requires purchasing a programmable nitrous controller. These controllers can be very beneficial, even for nitrous shots that are 100 hp or less, as they promote smoother power delivery, improved traction, and a reduced risk of engine damage. They include an input that can be triggered from a throttle position sensor or microswitch. Additionally, they come equipped with a built-in window switch that activates and deactivates nitrous delivery based on a specified rpm range. This feature helps prevent the nitrous from activating too early and ensures it shuts off when reaching a predetermined rpm limit, safeguarding the engine from potential damage.

Multistage systems offer even greater performance gains, but they are more complex to install and tune. These systems typically use a set of solenoids for each stage, which are jetted to deliver different levels of power at varying rpm levels. Such systems are designed for high-horsepower nitrous loads and are too advanced for this discussion. If you are building and installing multistage systems, you likely already know the ins and outs of nitrous systems.

Dialing in Your Setup

Nitrous kits typically include a chart that helps you select the correct nitrous and fuel jets for your desired horsepower levels. It’s important to remember that fuel pressure can affect the required fuel jet size. For instance, if you’re using pump gasoline with a carbureted fuel pressure of 5.5 to 7 psi, a 100-shot fuel jet kit would generally require a jet size around 40. In contrast, if you have a 100-shot kit operating at 45 psi with an EFI system, you will need a jet size around 27 for the same power rating.

Many kits specify fuel jets on the rich side for the engine’s safety. Always start with the recommended sizes provided in the kit before making any further adjustments. Additionally, it’s crucial to use a wideband oxygen sensor to monitor the air/fuel ratio, as well as inspect spark plugs to check for signs of detonation or fueling issues, especially if you decide to change the jetting for any reason.

As mentioned earlier, nitrous oxide chemically enhances an engine’s performance by adding additional oxygen and fuel. This results in higher cylinder pressures, necessitating corresponding adjustments to the ignition timing. A common guideline is to reduce the ignition timing by 2-4 degrees for every additional 100 horsepower gained. For instance, if your vehicle has a peak timing of 34 degrees when naturally aspirated, you would reduce this to 30-32 degrees for a 100-shot of nitrous or to 28-30 degrees for a 150-shot. It’s better to start with more timing reduction and then work back with tuning.

Timing adjustment can be made by either changing the timing at the distributor, ECU tuning, or using an ignition box that includes a timing retard step input. One advantage of using an ignition box with this feature is the engine maintains full timing while driving naturally aspirated; retaining all its power. Additionally, ignition boxes include multispark output for hotter ignition and a rev limiter to protect the engine from potential over-rev damage.

Nitrous applications, especially those using a 100-shot or higher, require the use of colder spark plugs to effectively manage the excess heat in the combustion chamber. Colder spark plugs dissipate heat more rapidly from the combustion chamber to the cylinder head. This helps prevent detonation in high-performance applications that experience increased cylinder temperatures and pressures, such as those with turbochargers, superchargers, or nitrous systems.

A non-projected spark plug with a nickel-alloy body and a copper core is recommended for nitrous. The term “non-projected” refers to the design of the spark plug’s insulator nose, where the tip of the center electrode extends less into the combustion chamber. In contrast, a projected spark plug extends further into the combustion chamber to improve flame propagation. The non-projected design offers several advantages, including better thermal conductivity and increased resistance to detonation, making it particularly suitable for the high combustion temperatures often found in nitrous or boosted engines.

While nickel-alloy plugs do not last as long as platinum or iridium plugs, they melt at lower cylinder temperatures, making them more forgiving if the engine tune is off. According to NGK, there have been instances where platinum-tipped plugs have lost their bond to either the center or ground electrode when used in motors with nitrous, and these types of plugs should be avoided.

The temperature of a nitrous oxide bottle affects the pressure inside, which in turn impacts the flow rate and performance. As nitrous is used, the bottle cools and pressure drops, reducing flow. A nitrous bottle heater helps maintain the temperature and pressure, ensuring consistent nitrous delivery to the engine. It keeps the pressure within the optimal range of 900-1,000 psi, preventing performance loss and allowing the bottle to deliver the full intended amount of nitrous. A bottle blanket can also help maintain stable pressure by insulating the bottle from outside temperature fluctuations and shielding it from the sun and physical damage.

Conclusion

A properly installed and well-tuned nitrous system can significantly enhance performance and improve acceleration. The exhilarating “hit” from the nitrous provides an exciting experience, delivering instantaneous power that is sure to bring a smile.

When considering nitrous systems, it’s important to remember that there’s more to think about than just the basic kit. Upgrades such as nitrous controllers, ignition enhancements, air/fuel ratio monitoring, bottle temperature management, safety switches, and proper tuning can greatly impact reliability, performance, and the overall experience.

Once you have your system dialed in, maintaining a nitrous bottle is all that’s needed. Many users keep two or more bottles on hand to minimize refill trips and ensure a steady supply, especially for racing purposes.

No matter which direction you choose to go with nitrous, SummitRacing.com has everything you need and a knowledgeable staff ready to provide guidance.

Comments