Seriously folks, if you want to make some serious power, is there any better way than adding boost?

This statement applies to almost any engine combination, regardless of the original level of performance, but even more so once you apply mods to your motor.

Truth be told, boost comes in many forms. You could choose any of the number of different types of superchargers, including roots, centrifugal or twin-screw blowers. All three of the blowers offer their own distinct boost curves and levels of performance, but for our modified 6.0L LQ4 motor, we chose turbocharging.

While turbos offer advantages over supercharging, they are not without their own limitations. If one type of forced induction was vastly superior to all others, there would only be one to choose from. Don’t get wrapped up in an individual superiority complex, but rather revel in the fact that life is awesome because we have so many to choose from!

Calculating Power Gains from Boost

Regardless of your choice, the supplied boost simply acts as a multiplier of the original power output. What exactly do we mean by this? Well, if you start with (for example) a 350 hp LS motor and add boost, you can double the power output to 700 hp by running 14.7 psi (one additional atmosphere).

The formula works for any given boost level as a percentage of the 14.7 psi.

If you add 10 psi to the 350 hp motor, you can improve the power output by 0.68, rounded up to 68% (10 / 14.7 = 0.68). This would equate to 588 hp.

Another way to get there is to figure out the gains offered per pound of boost. If we divide the original power output of 350 hp by 14.7, we see that each pound of boost would be worth 23.8 psi. If we multiply that by 10 psi, we get a gain of 238 hp (350 + 238 = 588 hp). The results are the same (that’s how math works), but you can see that adding boost to your motor can significantly improve the power output.

Adding Other Upgrades for Improved Boost Performance

Things get even better when you make modifications to the motor to improve the normally aspirated power before adding boost.

To illustrate how boost works on a modified motor, suppose we add a cam to our 350 hp LS motor and increase the power output to an even 400 hp. If we then add the same 10 psi of boost, we see that the 68% gain will increase the power output to 672 hp (400 x .68 = 272 hp + 400 = 672 hp).

Put another way, each psi of boost is worth 27.21 hp (400 / 14.7 = 27.21 hp).

By increasing the power output of the normally aspirated combination from 350 hp to 400 hp, we increased the power output of the turbo motor by 84 hp at 10 psi. The gains get even greater as we go up in boost. If we apply one atmosphere of boost (14.7 psi) to the 350 hp combo, we can produce 700 hp, but if we apply the same boost to the 400 hp motor, we get 800 hp!

The 50 horsepower gain made to the normally aspirated motor translated to 100 extra horsepower at 14.7 psi. Such is the benefit of building a powerful NA combination before adding boost.

Testing for Real World Power

Now that we understand the math, let’s apply some boost in the real world, or more accurately to a 6.0L LQ4.

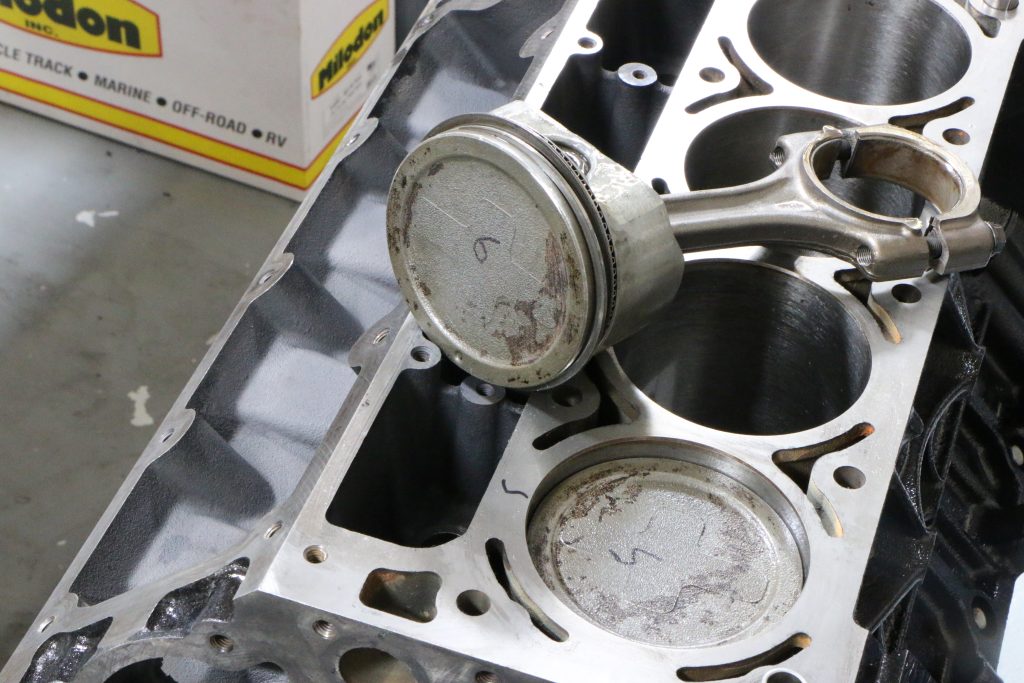

Before adding boost, the LQ4 was modified in the traditional fashion, meaning heads, cam, and intake. The short block was left surprisingly stock, with only a ball hone, deck surface, and re-gapping of the rings.

To the stock short block, we added a Stage 3 Turbo cam from Brian Tooley Racing. The Stage 3 stock offered 0.609/0.610 lift split, 230/235 degree duration split and 114 +4 degree LSA. According to BTR, the cam was purposely ground for use on a turbo application, but still managed to produce impressive power when we ran the modified 6.0L normally aspirated.

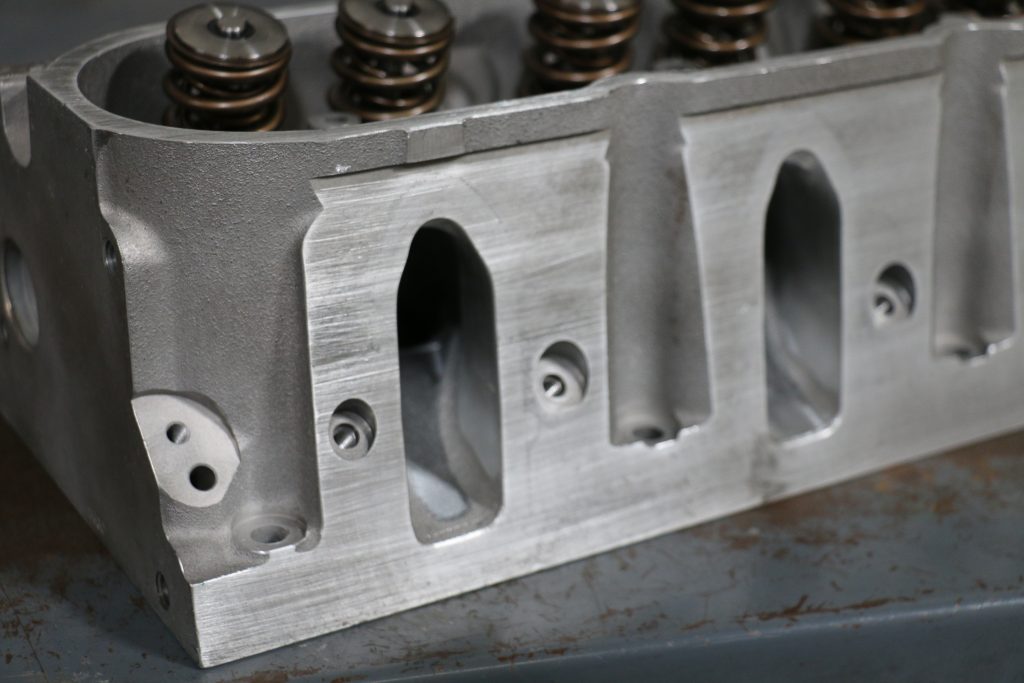

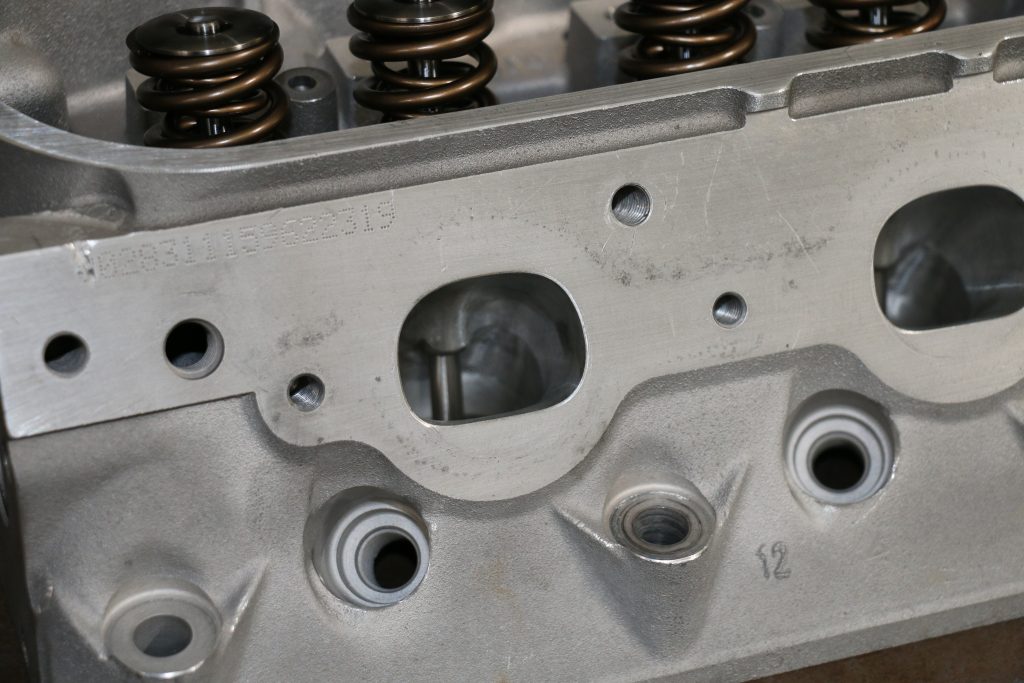

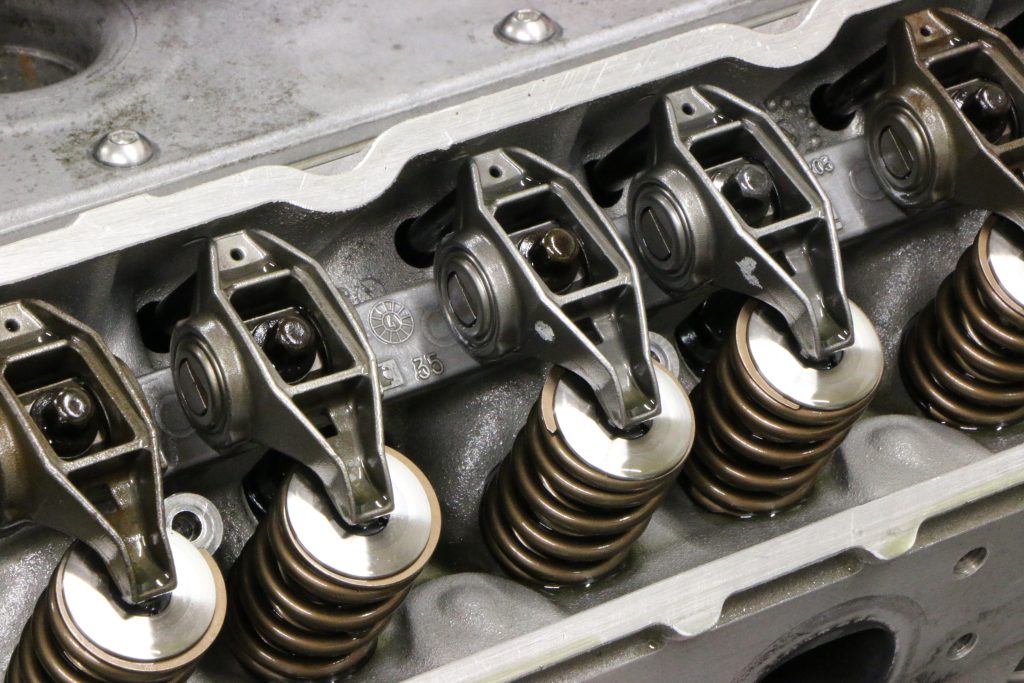

The cam was teamed with a set of Stage 2 317 heads from Total Engine Airflow. Since the 317 truck heads share the same ports as the performance-oriented 243 castings, the results of the porting were impressive. The heads also received a new valve combo and dual-spring package to further enhance performance.

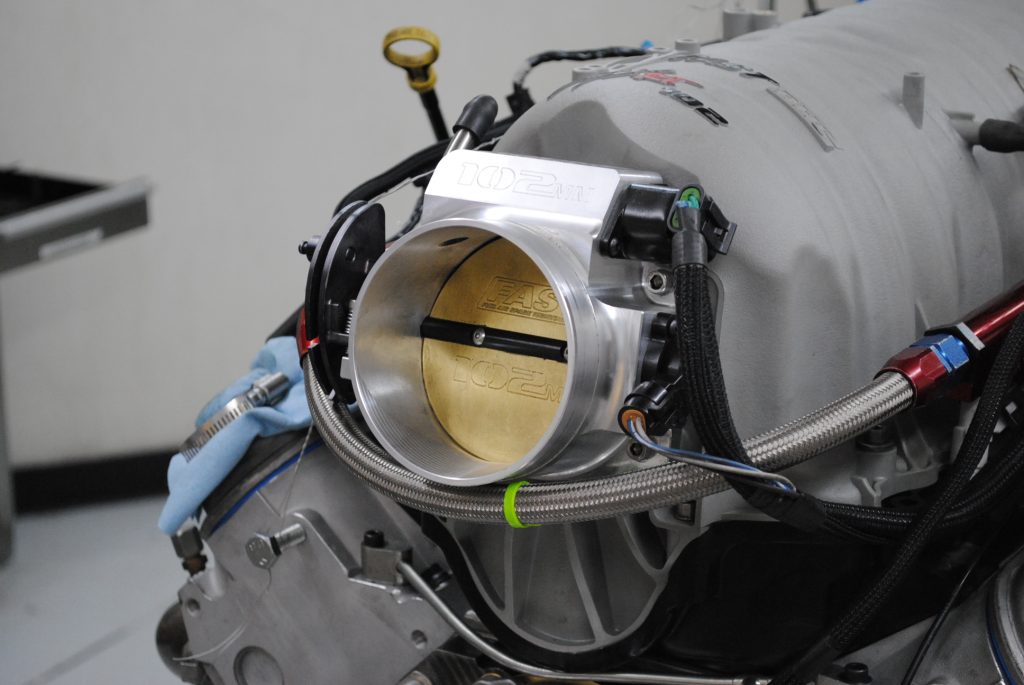

The final touches included a FAST LSXRT intake, 89 pound injectors and 102mm Big Mouth throttle body.

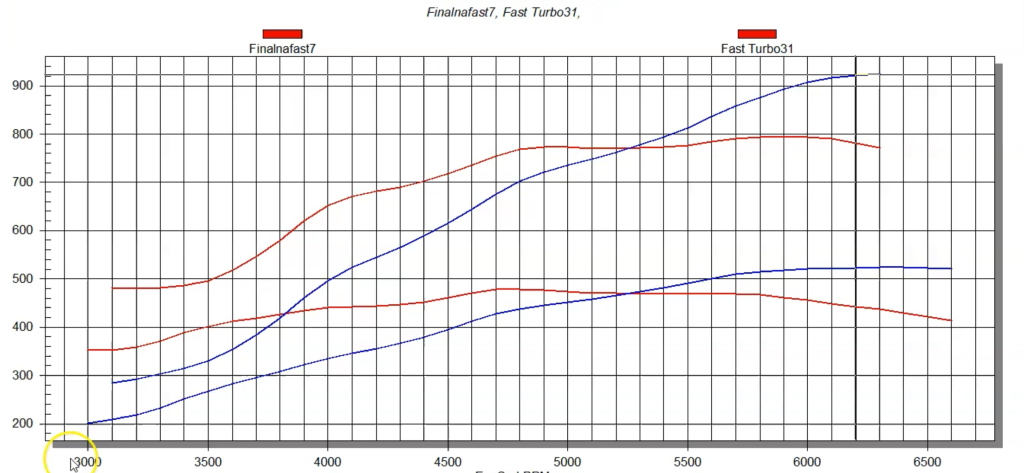

Run on the dyno, the modified 6.0L LQ4 produced 524 hp at 6,300 rpm and 479 lb.-ft. at 4,800 rpm.

Adding Boost

Satisfied with the power output of the naturally aspirated 6.0L, it was time for some boost.

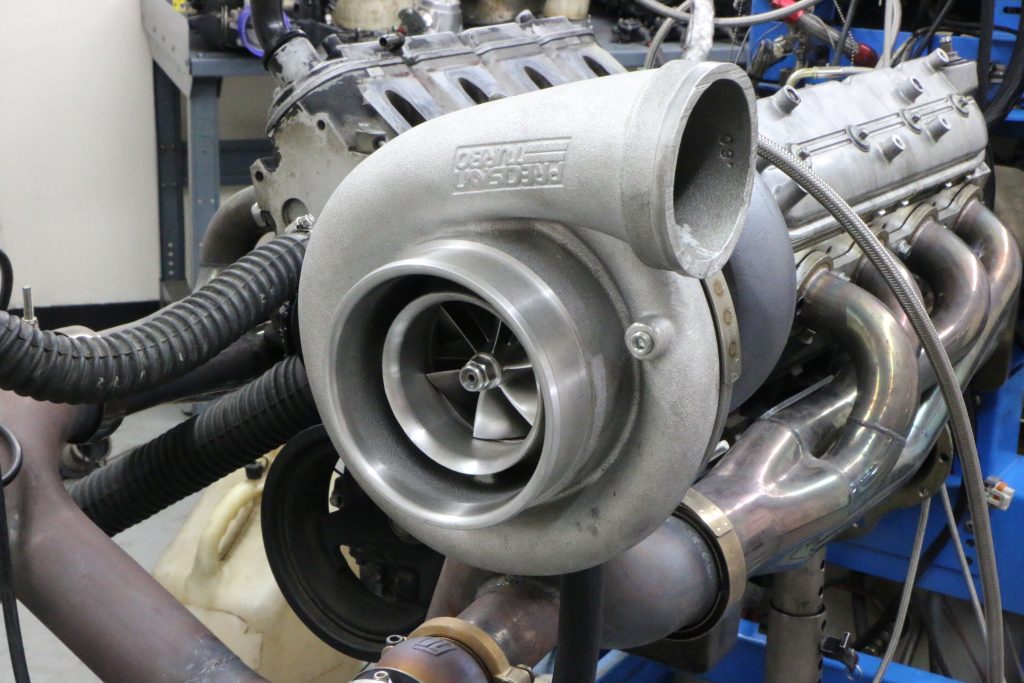

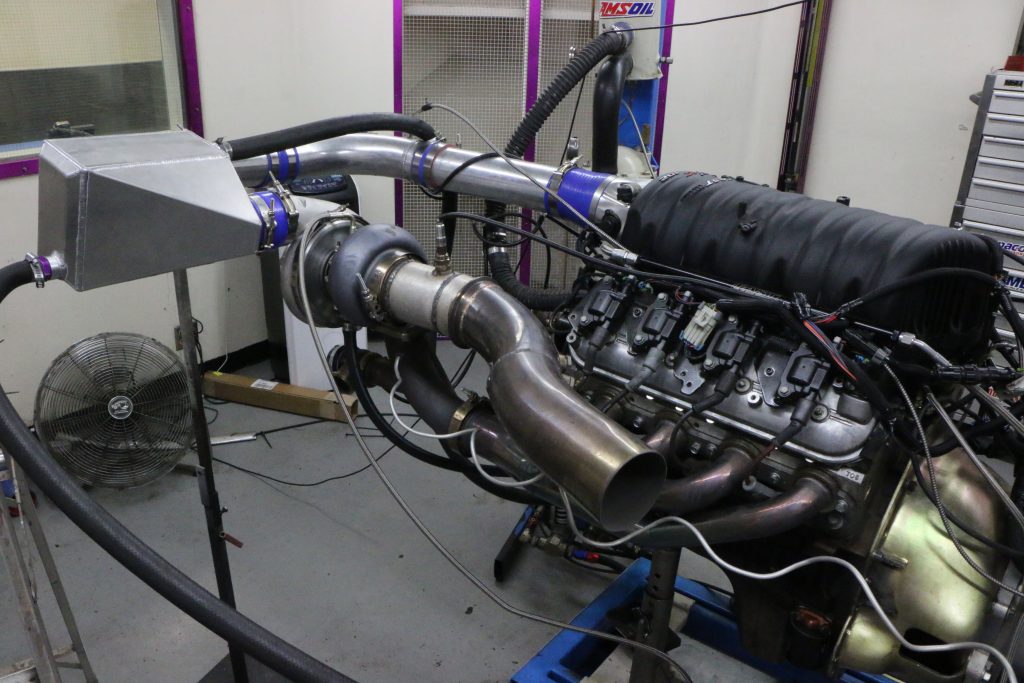

The single turbo system was less of a kit and more of a combination of components. Supplying boost was a single (but capable) 7675 CEA ball-bearing turbo from Precision Turbo. Capable of supporting over 1,200 horsepower, the turbo was nowhere near maxing out on this 6.0L application.

Feeding exhaust to the turbos was a set of DNA stainless turbo headers and custom Y-pipe. The fabricated Y-pipe featured three inch V-bands on each side along with a dedicated T4 turbo mount. The Y-pipe also featured a pair of provisions for the 45mm Hyper-Gate wastegates from Turbosmart.

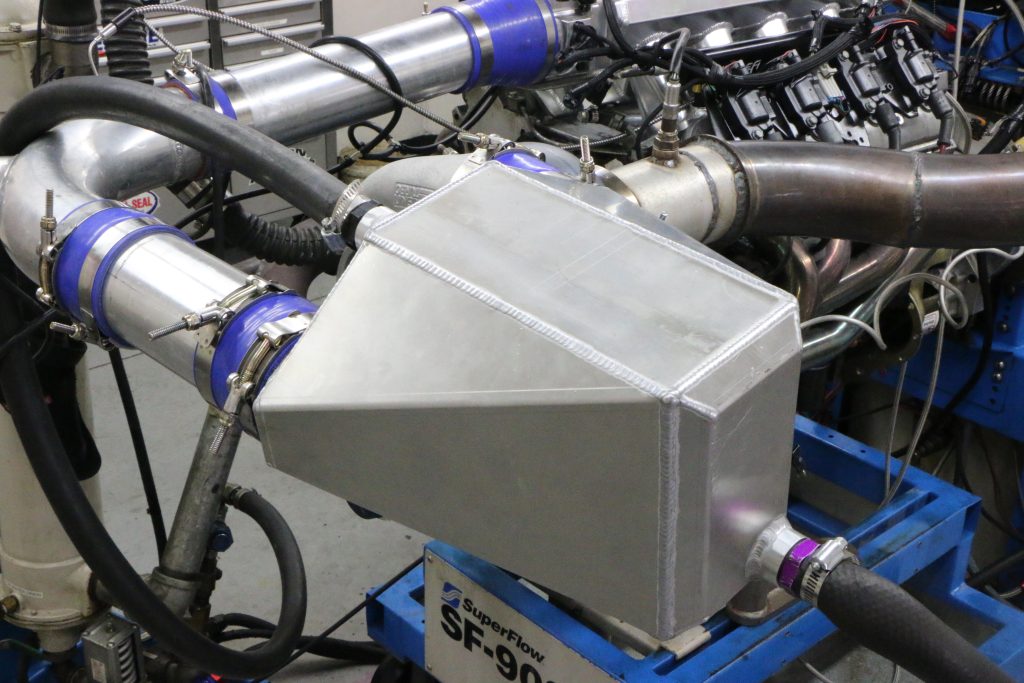

Boost was fed to an air-to-water intercooler from ProCharger while exhaust exited through a single 4.5 inch exhaust tube.

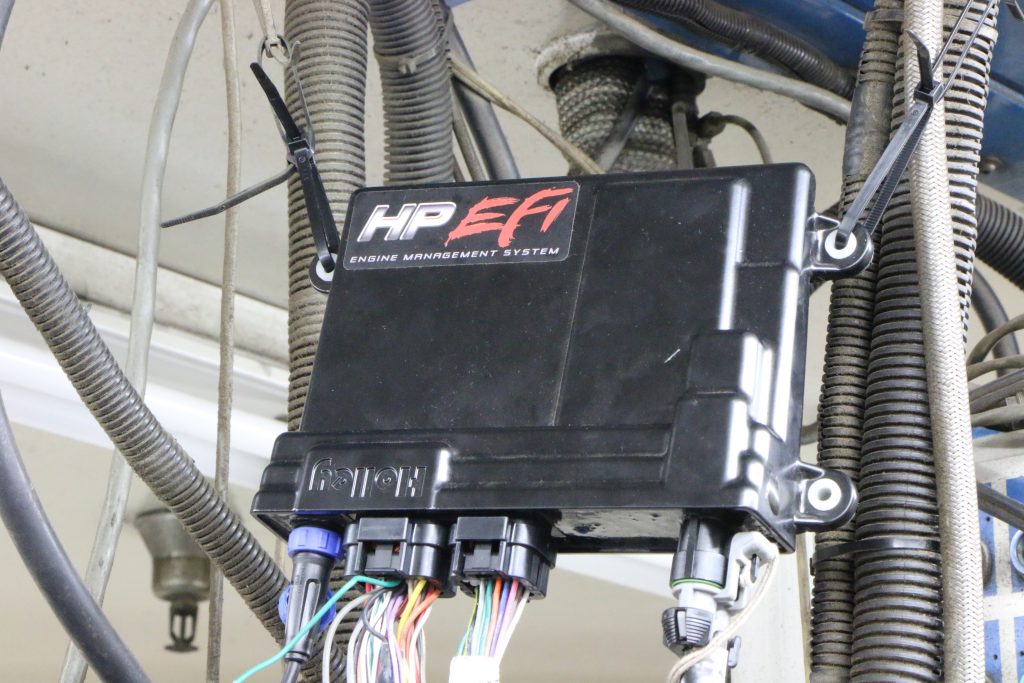

Dialed in with a peak of 10.6 psi of boost, the turbocharged 6.0L pumped out an easy 929 hp at 6,500 rpm and 796 lb.-ft. of torque at 5,900 rpm. This equates to 39.7 hp per pound, or even better than the formula suggested level of 35.6 hp per pound (525 / 14.7 = 35.6), though the use of E85 certainly tipped the scale in our favor.

I guess it really is as easy as combining a healthy turbo with the right mods to your 6.0L LS.

Hi Richard, Bill Ballinger here. I have a 410 FE that I would like to bore to 4.065 so that I can use LS forged pistons with a 1.326 CH dished flat top, and 6.85 Molmar rods and.041 Cometic head gaskets with a 10.166 deck giving a.035 quench. The FE heads are 74 cc heads that floe 285/215 and a carbed blow through. I want to just reverse the iron log manifolds to a 2.5 inch pair of pipes to an S480 T06 volute, and 10 psi of boost. The intake is a Holley Street Dominator single plane and an 850 DP. 93 octane or E85 as needed. I’m looking for 800-900 hp. Does this sound like a good combination. 413 ci. And the S480 T06 should be a common diesel turbo. Do you think it would work well and spool well? Thank you