Can I use a set of 1992 to 1996 aluminum cylinder heads from a Corvette on an earlier small block Chevy? I have a chance to pick up a set of these heads fairly cheap. A buddy of mine says they won’t work but it appears the head bolt pattern is the same and they are used on a small block Chevy, so what’s the reason I can’t use them?

T.K.

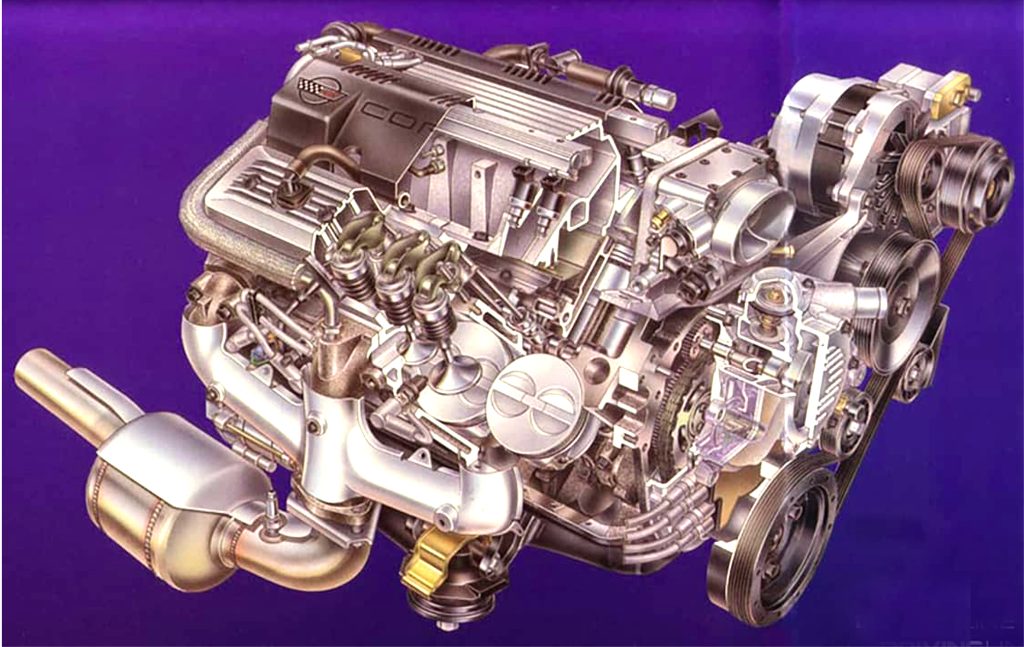

The heads you are referring to were used on the 1992 through 1996 second generation (Gen. II) small block engine that incorporated several major changes to the original small block Chevy V8.

The short answer is no—you cannot use them successfully.

Yes, they will bolt on with the standard small block head bolt pattern and yes the valvetrain will all line up, but the issue is that the cooling system is completely different.

Understanding the Gen. II LT1 Cooling System

It is possible to modify these heads to work, but the effort is way beyond practicality.

Besides, those Gen. II aluminum LT1 heads are only slightly better than earlier heads in terms of airflow so there’s no reason to make the effort. We need to get into how both cooling systems operate in order to fully explain why this swap won’t work.

The original small block Chevy designed in 1955 employed a simple cooling system. Pulling coolant from the radiator into the water pump, the coolant circulated through the lower half of the engine first, circulating around the cylinders. The coolant was pushed upwards into the cylinder heads and then directed forward through the heads into the common passage at the front of the intake manifold where the thermostat was located.

Once the coolant warmed up sufficiently to open the thermostat, the coolant was directed back to the radiator and the process repeated. This system worked fine but was not really all that efficient. The issue is that the hottest part of the entire cooling system is the coolant jacket area surrounding the combustion chamber. The old system pumped previously heated coolant around the chamber.

In the early 1990s, Chevy engineers decided that a better solution was to direct the coolant around the combustion chambers first, then push the coolant down past the cylinders and then exit the block and back to the radiator.

This has been called a reverse direction cooling system.

The problem with this system is that normally created air bubbles tend to collect in the top of the engine where the previous system swept them away.

This change in cooling system movement demanded entirely different water passages in the head and block of the Gen. II engines. This is why you cannot use the Gen. II heads on a Gen. I small block.

Sure, the head bolts all line up—but the coolant passages don’t and that’s the problem.

It is not worth the effort even to attempt this conversion because there are far too many good aftermarket small block Gen. I heads available.

A Note on the 1980s Gen. I “Reverse-Rotation” Cooling Systems

It’s also worthwhile to mention that there is some confusion about the later, but still traditional, Gen. I small blocks starting in the 1980s that use a reverse rotation water pump and serpentine belt accessory drive.

These engines employ the original small block cooling system but used a reverse rotation water pump because the pump is driven by the back side of the serpentine belt. This demanded that the pump spin in the opposite direction which changed the pattern on the pump vanes.

But despite this change, these engines retain the Gen. I small block traditional cooling system.

SBC Cylinder Head Options

You didn’t mention what cylinder heads are on your current small block. Let’s assume (I know, that’s dangerous) that you have an older Gen. I 350 with stock, smog heads. Let’s also assume these are small valve heads with large 76cc combustion chambers and the stock compression ratio is perhaps 8.75:1 (or something like that).

A much smarter—and not expensive—move would be to convert to a set of iron Vortec heads. These heads use 1.94/1.50 inch valves but offer far superior intake and exhaust ports in terms of airflow. These heads will actually outflow the aluminum Gen. II LT1 heads you were considering, so these Vortec heads offer an immediate advantage.

True you don’t get the light weight of the aluminum heads, but they do flow better. These heads do require their own specific intake manifold pattern so keep that in mind as well.

Jeff out here saving people everyday! I dont think there is a question that could stump this man. Thanks for sharing as always.