How much horsepower would I gain by converting my 6.0L LS engine over to an electric water pump? It seems to me that the water pump is the biggest demand on the engine and if it’s worth 20 hp it might be worthwhile to run an electric pump on my street/strip Nova.

D.B.

Accessory drives are a necessary evil with any street-driven vehicle. A typical accessory drive will spin a water pump, alternator, power steering pump, and often an air conditioner compressor. We’ll focus this discussion on the water pump since this device is the one that will consume the most power.

Converting to an electric pump, as the following test will confirm, will improve power above around 3,500 rpm but this will require a high output pump to properly cool the engine at sustained high speeds. Electric water pumps like those from Moroso or Meziere are quite powerful and can provide adequate cooling for a drag car. Meziere does make a high output electric pump for an LS engine for example that includes an over-running pulley to allow use of the stock accessory drive—but this is an expensive proposition (we’ll post a full parts list at the bottom of this article). This is capable of 55 gallons-per-minute (GPM) of coolant flow, which is a free flow rating and not under pressure.

Power Improvements with a Meziere Electric Water Pump

We asked owner Don Meziere for further information on this pump. He told us that the pump only requires around 150 to 160 watts (12 amps at 13.2 volts) to drive, which is barely 0.12 horsepower—a pretty negligible number. He also shared a test they performed on a 2012 Camaro exchanging the stock mechanical water pump for the Meziere LSX High-Flow street pump (PN MEZ-WP319).

The Camaro pushed out 385 rwhp on Westech’s chassis dyno and, after the swap to the Meziere electric pump, power improved to 391 rwhp for a gain of 6 hp. (Meziere mentioned that the air became much warmer in the afternoon which did not help the electric water pump power numbers.) One advantage to the electric pump beyond the horsepower improvement is that at low speeds it will likely out-perform the mechanical pump, producing a more efficient cooling system.

Meziere also told us that their testing also revealed that above 6,500 rpm the stock mechanical pumps tended to cavitate quite badly which radically reduced flow and would likely increase the horsepower requirement.

Stock LS Accessory Drive Water Pump Comparison Test

A few years ago, I was on a similar accessory drive quest and performed a simple engine dyno test at Westech where we bolted a complete truck accessory drive assembly to a 6.0L engine that drove the water pump and an alternator and we substituted a simple pulley in place of the power steering pump.

The test consisted of running the above accessory drive but with no electrical load generated by the alternator. In effect, we were really testing just the load placed on the engine by the water pump and whatever power was required to spin the alternator and the belt system. Then we removed this entire system and replaced it with a simple electric water pump.

The power difference was significant (check out the chart below). At low rpm, we actually saw a slight loss in power but we were using a stock 6.0L GM computer and we did not change any tuning settings. Had we tuned the system a little, I think we would have seen 1 to 2 hp gain instead of a loss. Above 3,200 rpm we began to see a gain in power that gradually increased to 11 hp at 5,800 rpm which was the highest engine speed we tested with that pure stock 6.0L Had we tested at a higher rpm like 6,500, the difference would have been even greater—perhaps as much as 15 hp or more.

This is an abbreviation of a basically stock Gen III 6.0L iron truck engine on the engine dyno at Westech several years ago comparing the OE truck accessory drive versus an electric water pump. The stock truck accessory drive drove the water pump, alternator (not charging), and an idler pulley in place of the power steering pump. Note that if we had spun the engine up to around 6,500 rpm—the gains would have likely been even higher.

Stock LS Accessory Drive vs. Electric Water Pump Power Output

| RPM | HP with Stock Acc. Drive | HP with Elec. Water Pump | HP Difference |

|---|---|---|---|

| 2,600 | 184 | 183 | -1 |

| 2,800 | 202 | 200 | -2 |

| 3,000 | 225 | 223 | -2 |

| 3,200 | 243 | 244 | -1 |

| 3,400 | 259 | 260 | +1 |

| 3,600 | 278 | 280 | +2 |

| 3,800 | 297 | 300 | +3 |

| 4,000 | 313 | 317 | +4 |

| 4,200 | 329 | 333 | +4 |

| 4,400 | 343 | 348 | +5 |

| 4,600 | 356 | 361 | +5 |

| 4,800 | 364 | 370 | +6 |

| 5,000 | 365 | 372 | +7 |

| 5,200 | 364 | 373 | +9 |

| 5,400 | 358 | 367 | +10 |

| 5,600 | 350 | 360 | +10 |

| 5,800 | 340 | 351 | +11 |

We have a theory that the truck water pumps are designed to work at low speeds to improve cooling efficiency below 5,000 rpm but might cavitate at speeds above this rpm—while the more performance oriented engines (like the ones in the Corvette and Camaro) would use a pump that is designed to move coolant more efficiently at higher engine speeds.

Dayco & Edelbrock Water Pumps

Dayco is a name manufacturer of quality water pumps, belts, and accessory drive components. We asked our friends at Dayco if they had any test data on pumps they’d be willing to share. Their testing revealed that all the Dayco LS pumps perform fairly close to each other at all engine speeds. However, the LS7 pump is slightly better than either the truck pump or the LS1 pump for power. Unfortunately, the tests were limited to 3,900 rpm but did show measurable reduced power requirements.

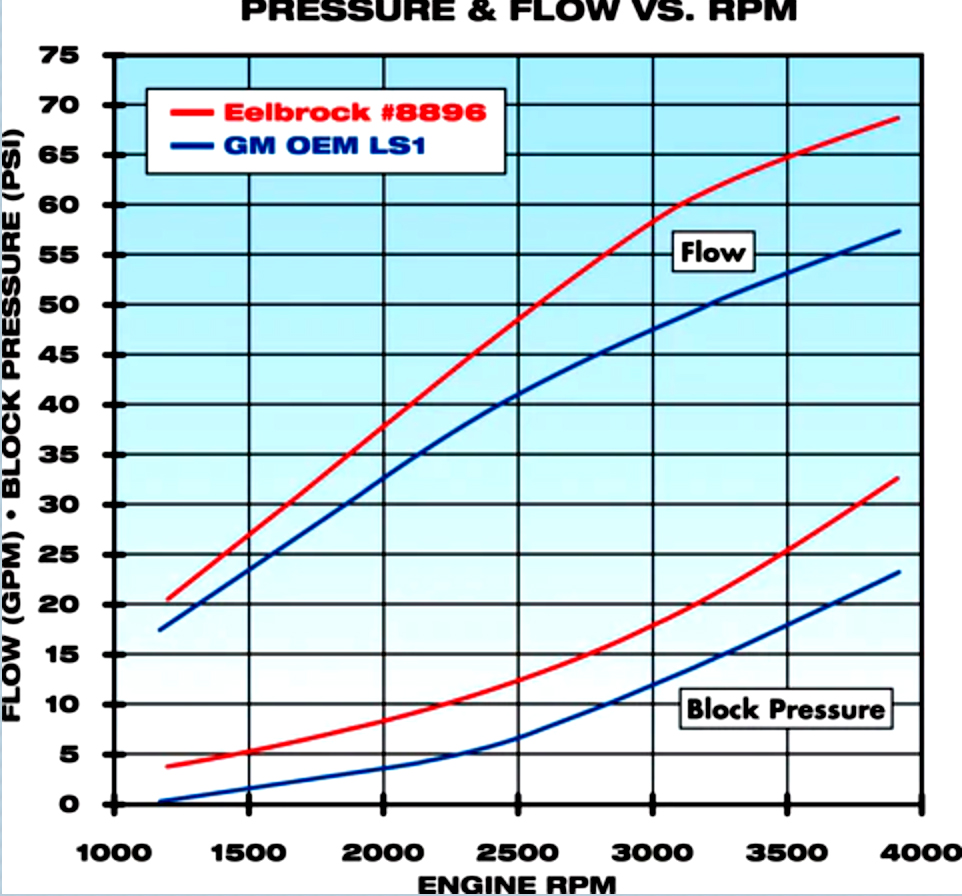

Then we contacted Edelbrock to see if they had any test data around claims that the Edelbrock mechanical water pump was superior to the OE LS1 pump. They sent us multiple test results that revealed that the Edelbrock pump can both outflow the OE pump but also does so with more even pressure across both sides of the block—and accomplishes that while reducing the horsepower demand.

The graph below shows the flow test results where the Edelbrock pump manages to increase the flow from roughly 10 gpm from 58 to 68 gpm which is a 17 percent increase in flow. Plus, cooling system pressure is also improved which will increase efficiency.

Part of the test procedure was to measure horsepower requirements based on pushing the coolant through a certain diameter orifice. As you might expect, the smaller the restriction, the more power required to push a given volume through the restriction. Unfortunately, we don’t have an accurate correlation between these restrictors and what the flow limitation that would represent, for example, an LS engine.

Based on Edelbrock’s data compared to the OE pump, it appears that there would be an advantage to adding an Edelbrock pump and turning it slower with a smaller diameter crank balancer. The combination of these components would not only maintain cooling efficiency but also improve horsepower compared to the stock pump and drive assembly.

Keep in mind that increasing block coolant pressure reduces the chance for bubbles to form around the combustion chamber. This improves heat transfer from the hot portions of the chamber to the coolant to reduce the chance of detonation which might allow you to run slightly more aggressive ignition timing.

It’s little things like these that make the difference between mediocre engines and strong ones.

Of course, the Edelbrock water pump is more expensive than a replacement water pump, but if you are searching for more power for a street-driven engine, this might be one place where better engine performance is worth the investment. Of course, another option would be a quality pump like the Dayco driven by the smaller harmonic balancer.

Granted, we are talking about improvements in the single digit category while the cost can be significant. The greatest improvements would be seen when spinning the engine 6,500 rpm and higher. In those situations there is potential for double-digit power increases.

***

LS Water Pump Upgrade Parts List

- Meziere electric LSX pump w/ pulley – MEZ-WP319

- Edelbrock LS1/LS6 water pump – EDL-8896

- Dayco LS1/LS6 water pump – DAC-DP1317

- Trick Flow 25% underdrive balancer, LS1 – TFS-18005

Comments