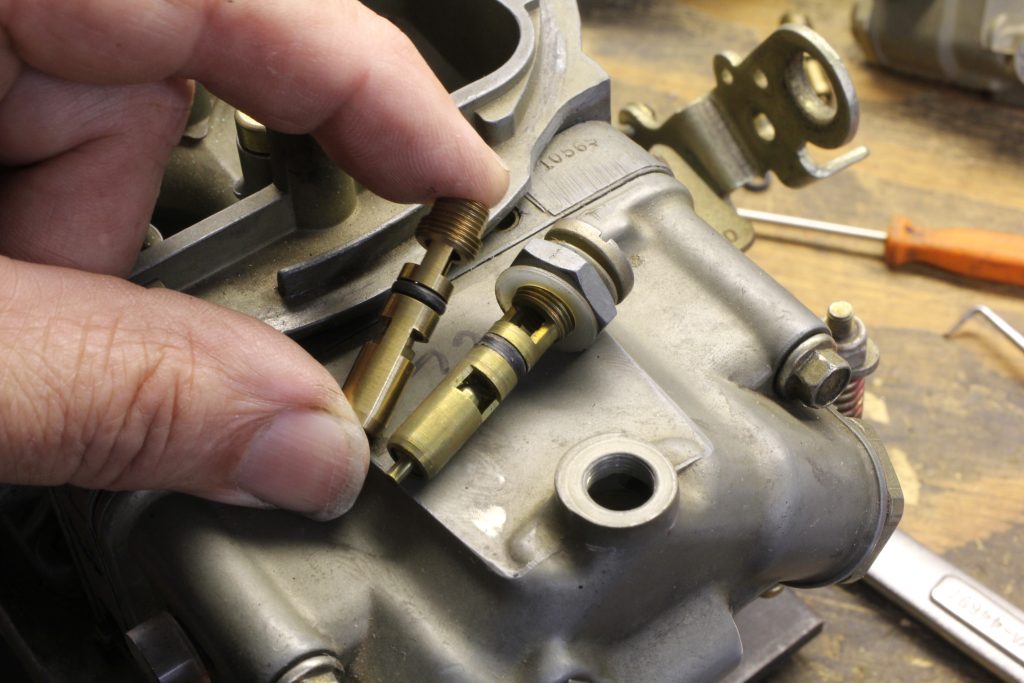

I’m having a real problem keeping my Holley carburetor needle and seat O-ring from leaking. My old Holleys worked fine up until about a year ago. Now it seems both of my carburetors for my two cars have problems. What happens is the carb will begin to flood over. I thought at first this was just a stuck float, but the float is fine and there was nothing holding it open. I traced the problem to a hardened O-ring around the needle and seat. But I can’t find this as a replacement part. Do you have any suggestions short of buying a brand new needle and seat that has the O-ring already in place?

D.W.

We’ve had the exact same problem with several of our Holley carburetors that only get used once or twice a year. What happens is the nasty aromatic additives in gasoline now are affecting this rubber O-ring and causing them to shrink, become brittle, and then break.

After some research, we found, like you did, that Holley does not offer this O-ring as a separate part number—but you can buy a new needle and seat assembly that will come with the correct O-ring. Summit Racing’s version of this same needle and seat is roughly half the cost so that makes it a little less expensive.

There’s a full parts list at the bottom of this article.

Holley also sells a needle and seat hardware kit (PN 34-7) that includes a new lock screw, adjustment nut, both paper gaskets, and a new O-ring. It would be a good idea to order a couple of these kits around just for the O-rings because we’ve seen these paper gaskets leak after adjustments.

If you are forced into an immediate repair, you can replace the original O-ring with a 08-size buna rubber O-ring that is pretty easy to find. We’ve learned these rubber O-rings only last maybe a month or two and then they quickly become brittle and the leak reappears. We searched a little further and found a company called Allstate Carbs that sells the proper O-ring for the Holley needle and seat and they are very inexpensive.

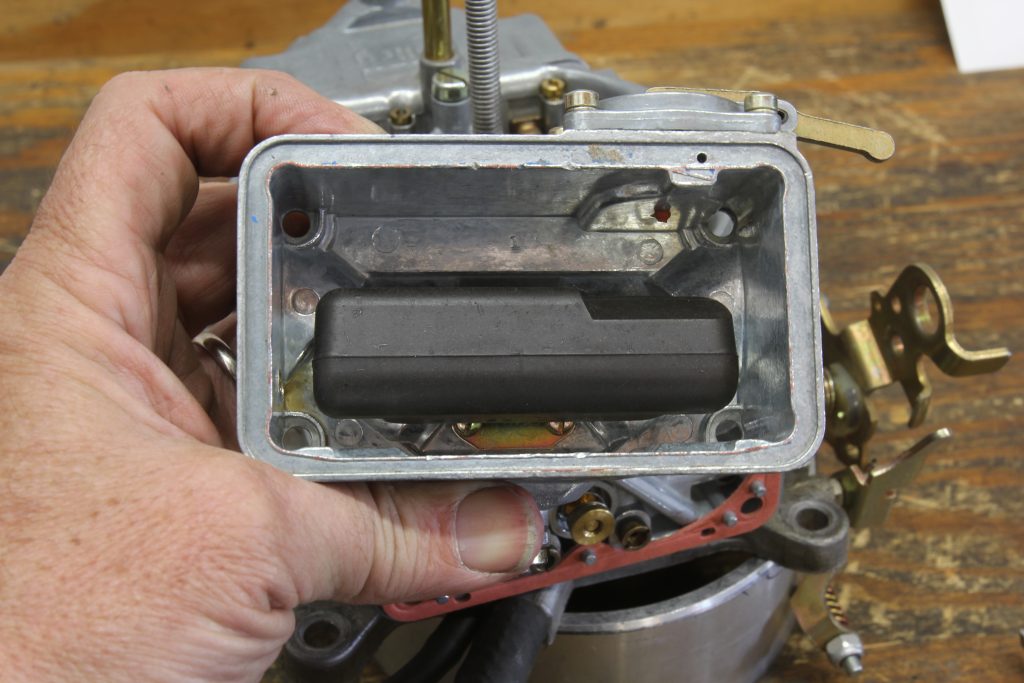

We’d recommend removing the float bowl in order to properly set the float height. Before you do so, make sure you have a new bowl gasket on-hand since these gaskets tend to get brittle and tear, which will prevent re-installing the bowl. It’s also a good idea to have a couple of those screw gaskets that fit between the adjustment nut and the lock screw on the needle and seat too, as these can tear and leak as well.

All this sounds like a hassle, but it’s better to have these parts on-hand rather than to get halfway through the process and discover that you need parts that you don’t have. Plus, it’s always a good idea to have these gaskets and parts available anyway since you never know when you may have to disassemble your carburetor for service.

Leaky Carburetor Repair Parts List

- Holley needle and seat hardware kit – HLY-34-7

- Summit Racing 4150/4160 Holley needle and seat – SUM-200401

- Summit Racing 4150/4160 needle & seat hardware kit – SUM-200400

- Holley 4150/4160 needle and seat – HLY-6-504

- Performance Tool O-ring kit (402 pcs) – WMR-W5202

- Holley primary float bowl gasket – HLY-108-83-2

- Allstate Carbs Holley needle & seat O-ring

Dry setting the float level as shown, up-side-down, then place a number 2 pencil under the float. The pencil is almost perfect “feeler gauge”.

Adjust float accordingly. Usually that measurement is spot on at start-up.