I’ve got a 700-R4 in my Chevy C10 pickup behind a typical 383ci small-block Chevy. The engine runs fine with a set of Edelbrock heads and Performer RPM intake and a Holley 750 vacuum secondary carburetor.

My problem is the transmission doesn’t seem to be as strong on the up shifts as it should be. We were thinking that maybe the torque converter is a little too soft and that’s causing the weak shifts. Any thoughts?

W.D.

Yes and hopefully you have not hurt the transmission in the process. This sounds like a classic case of an incorrectly adjusted TV cable. This is a complex issue with a ton of other potential causes but we’re going to go with the best option of making sure the TV cable is properly adjusted because this is often where big problems begin.

The term TV is short for throttle valve. The TV cable on the 700-R4 and its cousin the 200-4R overdrive transmissions replaced the old vacuum modulator valve as the device used by the transmission to sense the load applied to the transmission.

How a Throttle Valve (TV) Works

On the top of the engine, the TV cable is connected to the throttle arm on the carburetor or throttle body if the engine is EFI. On the other end, the cable is directly attached to the throttle valve that adjusts line pressure in the transmission, much like the vacuum modulator did on earlier automatics. As the throttle opens, this pulls on the cable which moves the throttle valve inside the transmission valve body and increases line pressure.

All of this works very well in the stock OE configurations because the GM engineers worked out the details. Problems arise when hot rodders start changing components like carburetors or intake manifolds. Aftermarket carburetors like a Holley or an Edelbrock do not create a proper locating position for the TV cable because these carburetors were designed and built before the TV cable was created.

Properly Mounting Your TV Cable

It is critical that the placement of the TV cable on the throttle linkage be accurately placed to duplicate the OE movement of the throttle as it opens. Most often this also means that we will need a mount to position the TV cable assembly next to the carburetor.

To simplify things, several manufacturers like Holley and Edelbrock have come up with mounting kits. There are entirely too many kits to list them all here and we frankly don’t have the resources to test them to determine how well they work. So we’ve landed on a couple of products that work for us and also will be easy for you to adapt to your particular application of a Holley carb on a dual plane intake manifold. The parts we’ll be using are straight from Holley.

First we need a place to securely mount the TV cable to the manifold and carburetor to create a stable platform from which this cable can operate. We’ve found a simple bracket by Holley (PN 20-95) works well to create a secure place to mount a universal TV cable. The next step is to connect the cable to the transmission to make sure it is correctly attached to the transmission TV valve.

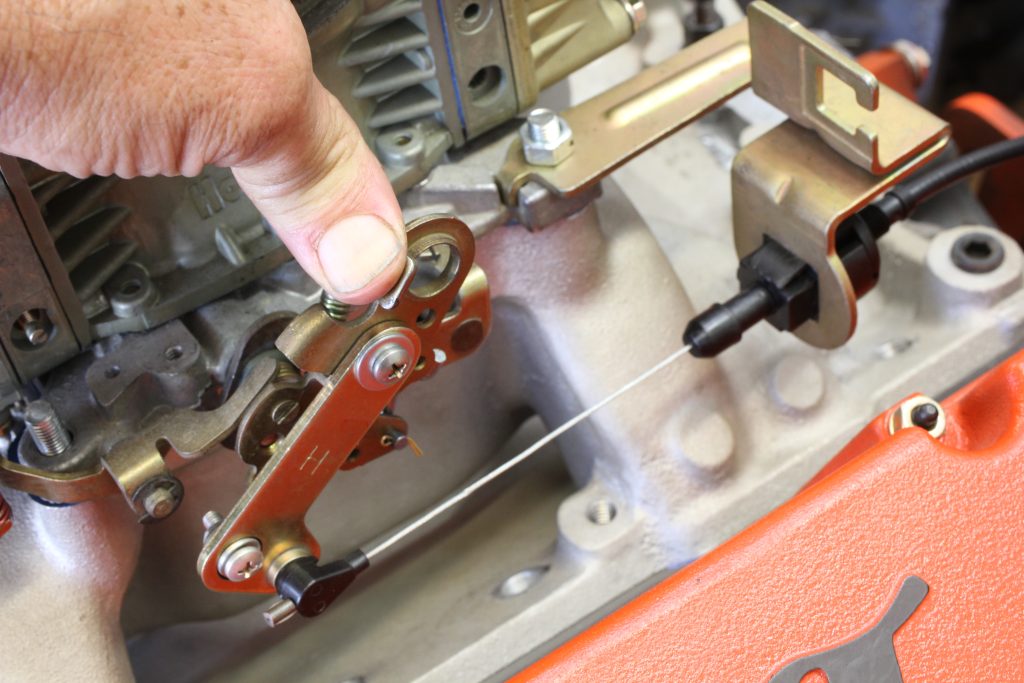

Now we need a simple TV adapter that bolts to the side of the Holley carburetor primary throttle linkage (PN 20-121). This bracket repositions the TV cable throttle linkage point to duplicate the TV cable OE movement required by the 700-R4 transmission throttle valve. This is especially crucial because it is this cable movement that signals the transmission that there is load applied to the transmission.

Adjusting the TV Cable

If the cable moves too far too early, the shifts are delayed and are more aggressive than what is considered acceptable. If the cable does not move far enough with light throttle movement, the line pressure remains low, the 1-2 and 2-3 shifts occur very quickly and early—these are often called stacked shifts.

Neither of these situations are acceptable. Plus, if the cable does not move far enough, line pressure is low and the clutches will not engage quickly enough which causes slippage which will soon destroy the transmission. This can happen in a matter of a few miles. We cannot over-emphasize how quickly this can happen.

Of course, there are other potential problems inside the transmission that can cause these issues. So the best way to set the TV cable is to do this along with a transmission line pressure gauge. All 700-R4 transmissions offer a small 1/8 inch pipe thread fitting on the driver side of the transmission positioned just over the shift linkage. Our recommendation is to connect a 300 psi pressure gauge to this port and monitor it constantly when setting up and tuning the TV cable. At the bottom of this article, we’ve included a pressure chart created by TCI, the automatic transmission people.

The key is to initially connect the TV cable to the Holley linkage on the carb and set the linkage up so that it is tight enough at idle that as soon as the throttle linkage moves past idle, the line pressure immediately increases. If this does not occur, this may indicate there could be internal problems with the transmission which is beyond the scope of this discussion. Also make sure your hydraulic pressures are consistent with the TCI specs. If they are excessively low or high that could indicates internal problems.

Hopefully this will point you in the proper direction toward improving the shift quality on your 700-R4 that will ensure your transmission lives a long healthy life and offers the opportunity for you to enjoy your truck over many thousands of miles of fun driving.

700-R4 Transmission TV Cable Parts List

- HLY-20-95 – Holley TV Cable Bracket, Mounts to Carb

- HLY-20-121 – Holley Transmission Kickdown Bracket, 4150/4160

- BMM-64511 – B&M Throttle Cable Adapters, Edelbrock Carb

- EDL-8026 – Edelbrock Throttle Valve Cable Adapter

- TCI-376800 – TCI Universal TV/Kickdown Cable

700-R4 Automatic Transmission Shift Points

| Gear Change | Shift Point |

|---|---|

| 1 - 2 | 15 - 20 mph |

| 2 - 3 | 25 - 30 mph |

| 3 - 4 | 40 - 45 mph |

700-R4 & 200-4R Min./Max. Pressure for Each Gear

| Gear Position | Minimum Pressure (PSI) | Maximum Pressure (PSI) |

|---|---|---|

| Park | 90 - 110 | 190 - 239 |

| Reverse | 90 - 120 | 200 - 300 |

| 1st | 190 - 230 | 190 - 230 |

| 2nd | 190 - 230 | 190 - 230 |

| 3rd | 190 - 230 | 190 - 230 |

| 4th | 190 - 230 | 190 - 230 |

| This chart indicates minimum and maximum pressures for each gear position in a 700-R4 and 200-4R transmission equipped with a TCV cable. This chart indicates minimum and maximum pressures for each gear position in a 700-R4 and 200-4R transmission equipped with a TCV cable. | ||

First step, check fluid level.

A friend had poor shifting and bringing the fluid up to the correct level cured it.

What RPM should be associated with those shift points?

Is there a rate of acceleration that needs considered?

I have a 1992 Sonoma gt 4.3V6 with factory 700R4 that has slight mods such as Vette servo, wide band all new internals new torque converter the check ball in the input shaft delete thought it was gonna be alright watched a video where they do reverse check ball delete in the valve body and about 3 other check ball deletes the valve body was already working b4 rebuild it lost 2nd and overdrive I believe but now I have to mash on it for 1st to 2nd shift keep in mind 1st works perfect once in second it works good then it will shift into 3rd and it’s seems good for 3rd but overdrive it goes in and out reverse works awesome so my question is should I put the correct amount of check balls back into the transmission and think it’s gonna go back to working right or should I look at other problems

I hav a 350 with a rochester quadrajet carb, do I need an adapter on my carb to hook up to a 700r4 transmission TV or detent cable

Thanks Gary

I HAVE A 383 MOTOR WITH 750 CARB 2800 STALL CONVERTOR 411 GEAR HOWE CAN I SLOW SHIFT TIMES. IT SHIFTS SO FAST INTO 3RD AND 4TH ITS HAS DETENT CABLE

I have a shiftier button that will not depress to get out of park, How do i check to fix? I had to hit the rod with a hammer to get it out of park. is there something that would make it stick, what should I start looking for. it started acting like this after car was parked for a few months. Car is a 1985 corvette.