I once viewed mock-up motors with a bit of disdain, asking myself why anybody would waste their money on one.

But then I started pondering my own project: Here I was with a car that I had completed to roller stage, and I was in the final throes of saving money in order to collect engine parts. I have just about everything except for the cylinder block, oil pan, and transmission. Because the pieces I want are expensive, it’ll be a while before I can afford them.

But there was something else.

I have a bunch of ancillary pieces I’ve collected for the car. They’re just sitting on the shelf, because I can’t finish things like final fuel line plumbing, spark plug wire routing, oil gauge plumbing, and water temperature sender wiring without an engine in place. So I’m stuck.

There’s also a pretty big issue with headers. In my stash, I have a set of large tube adjustable headers designed for the car, but there’s a lingering question: They’re designed for conventional exhaust port heads. The Brodix BB3 Xtra cylinder heads I’m using have the exhaust port raised a whopping 0.600-inch. The burning question for me is, will they fit?

On the top end, I had a hunch the Weiand Warrior single plane intake will not clear the stock flat hood. If it doesn’t, I only have three options: rework the intake, use a scoop, or run the car without a full air cleaner. The last two options don’t appeal to me, but I had to find out if it clears one way or another.

On the nose of the big block I had another dilemma: I have a mix of Brodix cylinder heads with an Edelbrock water pump mixed in with a Weiand intake coupled with a reproduction OEM style alternator bracket and an OEM Chevy alternator. This could be a recipe for trouble because they all have to somehow fit together (and fit in the engine bay too).

My car is set up for a large capacity mechanical fuel pump that incorporates an Enderle bypass valve on the top side. That means I have a large diameter AN hose feeding the fuel pump, a slightly smaller AN hose from the pump to the carburetor, and a return line to the tank from the bypass valve. I have a couple of large capacity pumps, but getting the right mix of fittings coupled with the correct orientation of the inlet and outlet on the pump (the inlet and outlet ports can be indexed, but not independently) isn’t easy.

There’s more too: I had previously fabricated a clutch linkage using rod ends and a combination of chromoly and swaged aluminum tubing. Would it fit? The transmission was next. I haven’t decided between a Jerico four-speed or a G-Force 101-A four-speed—maybe even a new Super Muncie four speed. I’m positive the G-Force will fit because it’s very close to the same dimensions as a Muncie. The Jerico, however, is a little taller, primarily due to the ribs on the top plate. Will it fit?

I pondered those basics.

And the more I thought about it, the more a mock-up motor and transmission started to make sense. Sure I could use a junk 454 block, but then I have to drag out my cherry picker to fit the thing in my engine compartment. All of a sudden, it becomes a big job. Plus there’d be no way to know if something like a Jerico would fit (you can’t find those easily in junkyards).

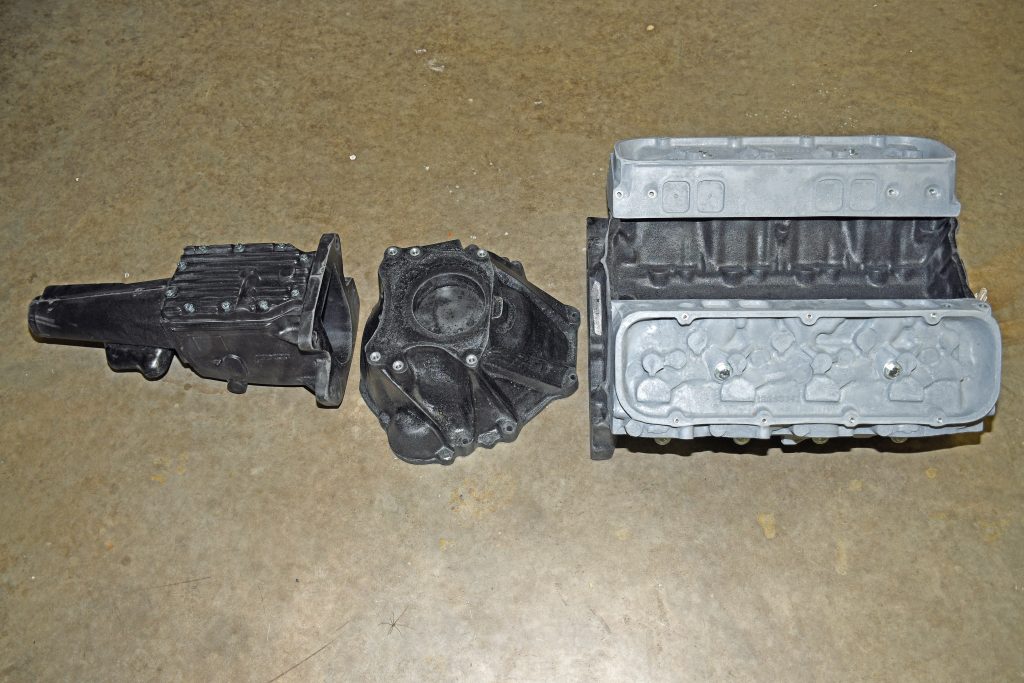

With that in mind, I came to the conclusion a mock-up motor and transmission from the folks at P-Ayr would prove invaluable. I could check part fitment and, at the same time, complete hours of sub-assembly work without having the real thing in place. P-Ayr makes all sorts of mock-up engines, transmissions, cylinder heads, and more.

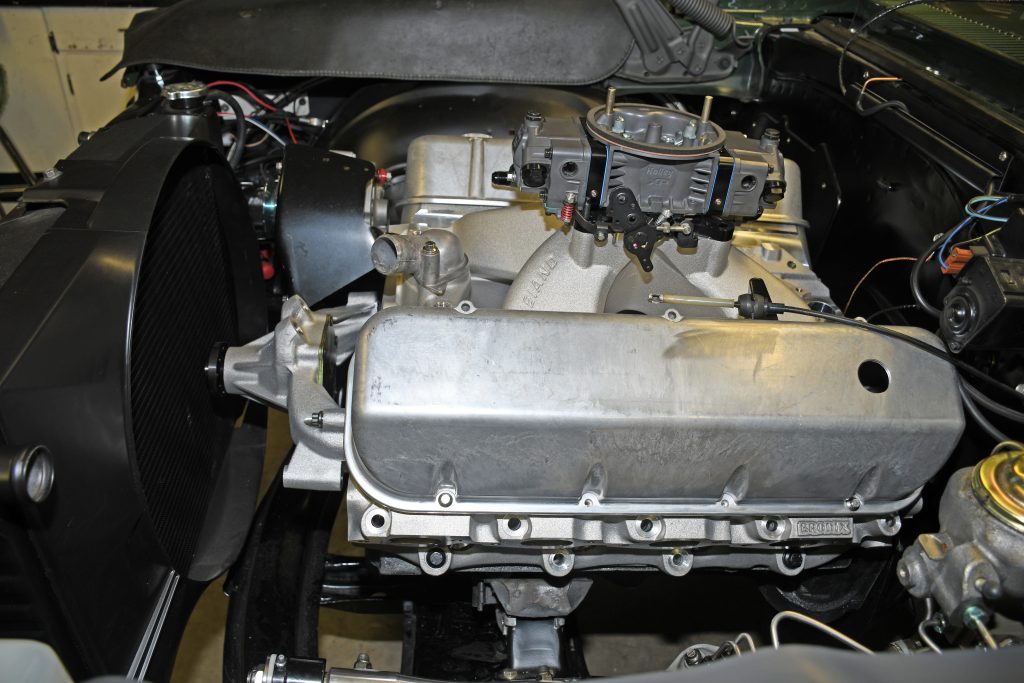

The folks from P-Ayr build replicas for anything from a Honda to a Hemi. You can get them as short blocks or with cylinder heads. You can also get them with removable heads (like the engine in the photos below).

Although not shown in the Summit Racing catalog, P-Ayr offers myriad popular transmissions (automatic and manual) along with bell housings, cylinder heads, carburetors, and even 6.71 blowers for various different engines (early Hemi, 426 Hemi, and Small and Big Block Chevy).

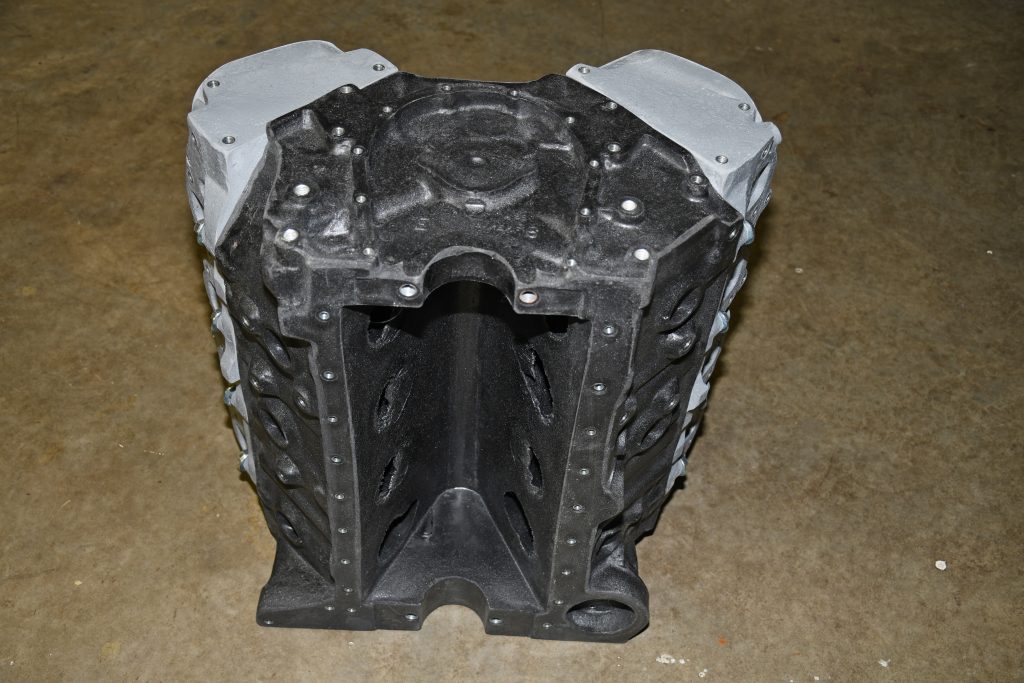

The P-Ayr blocks incorporate steel inserts for all critical bolt holes, and all specifications are held to OEM tolerances. This means you can bolt any factory component or accessory to a P-Ayr engine and it should fit. The blocks, heads, and transmissions are manufactured from a durable polyurethane foam.

They’re light and very easy to work with—which is kind of the whole point.

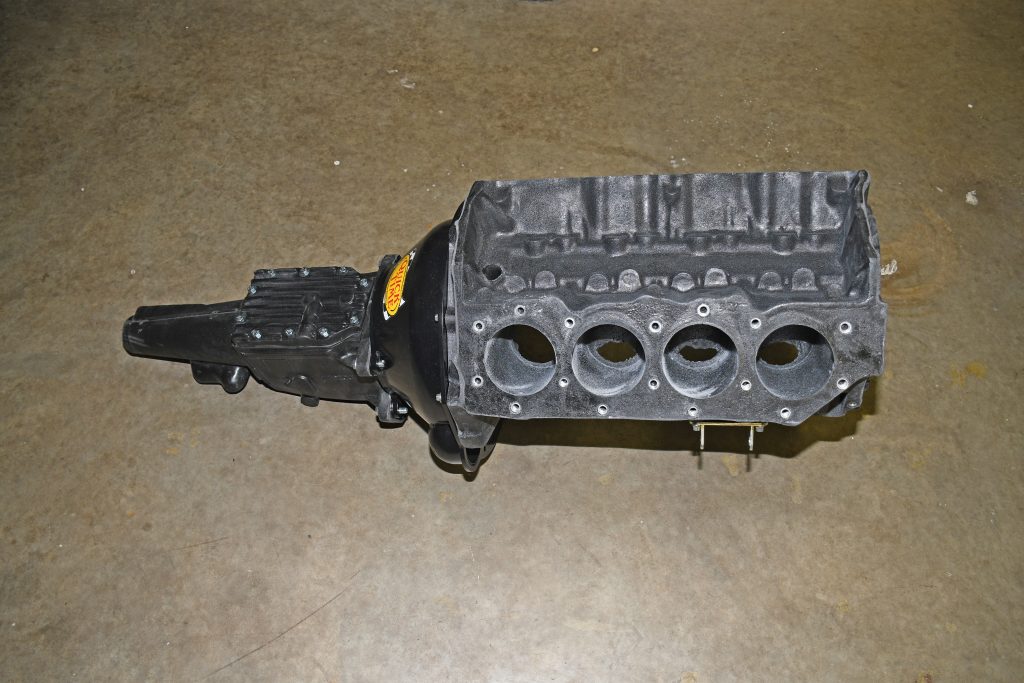

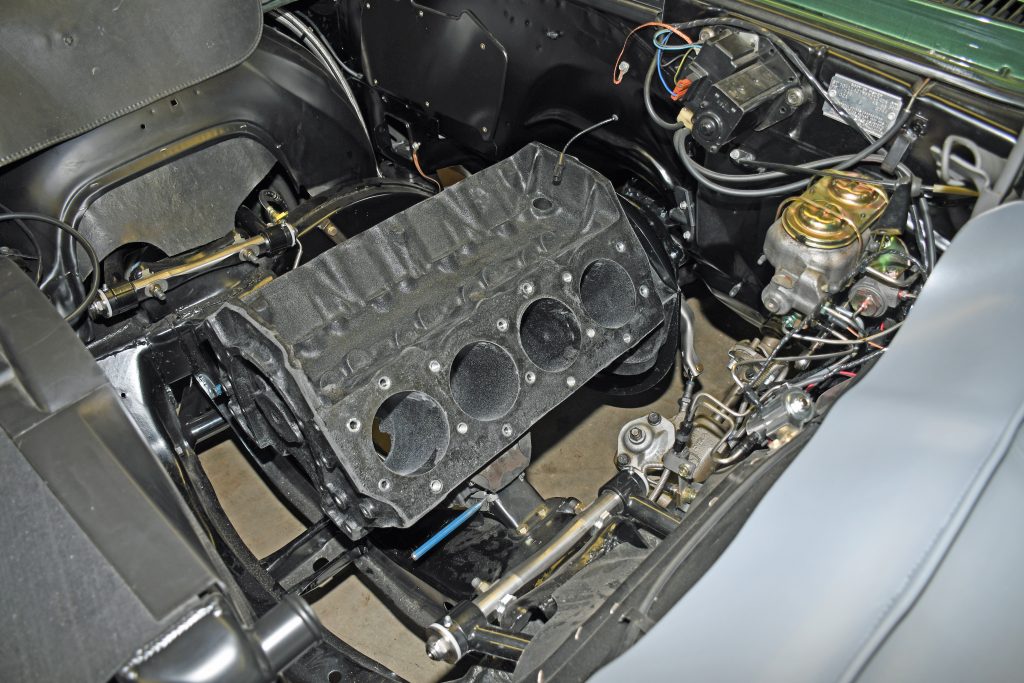

Once the mock-up big block and mock-up transmission arrived, I bolted them together, using my existing QuickTime bellhousing. I also added a set of solid motor mounts from my stash. So far so good. Everything was lowered in place (sans cylinder heads) but I didn’t get far.

I discovered the solid motor mounts I had were completely wrong. The engine wasn’t even close to fitting on the stock BBC frame stands. Out it came and I swapped the solid mounts for a set of OEM rubber mounts. Bingo. It slid into place, but I soon discovered the Jerico case doesn’t clear the tunnel easily when using a stock transmission mount, which answered another of my big questions. (Yep, I’ll be adding a G-Force or Super Muncie gearbox to my shopping list.)

I figured it was good time to bolt on my Brodix heads. They fit perfectly. Once installed, I tried to fit the headers. They didn’t fit. Oops.

But it wasn’t all bad news: If I moved one tube on the driver side and either moved one tube on the passenger side (or lightly dented it), I could make it all work. Moving a single tube can save you a lot of money when compared to ordering a full set of custom headers.

On the topside, my hunch on the intake was right. To clear the stock hood, I’ll have to angle mill the top and relocate the carb studs (a couple of places do this regularly). There’s more too: I discovered the right mix of fittings for my fuel pump and I can now fab the rest of the fuel lines.

As it turns out the alternator and alternator brackets fit nicely aside from one bolt hole in a support bracket that must be enlarged. My homebrew clutch linkage fits perfectly. I discovered the existing throttle cable is too short, but I have one on the shelf that’s slightly longer. I’ll replace it and see if it works.

I can make up the oil pressure line and fit the temperature sender wiring. My new valve covers (which were a stretch from a fit perspective) clear the factory wiper motor and at the same time, they’ll work with the Jesel shaft rockers I have on hand. The P-Ayr block is designed to accept a distributor, which means I can make up the spark plug wires ahead of time. I can also check the oil pan dimensions and safely order a pan for the car.

Once the headers are “fixed,” it allows me to fit and weld up the v-band clamp flanged on the reducers. I can actually set up and install the entire the exhaust system.

Whew. As you can see there are a lot of things you can do with mock-up parts. The pieces from P-Ayr fit perfectly. They’re light and, unlike junkyard iron bits, they won’t wreck your back, pinch your fingers, or scratch your paint. If I had a big fab project (a street rod for example) or an engine swap, one of the mock up motors and transmissions would prove equally valuable.

When you’re done with the parts, they store easily. You can stack them out of the way in your attic—that’s something you can’t do with junkyard iron parts.

Bottom line here is, the P-Ayr parts are “fabulous fakes” that I wish I would have considered sooner.

[…] I once viewed mock-up motors with a bit of disdain, asking myself why anybody would waste their money on one. But then I started pondering my own project: Here I […] Read full article at http://www.onallcylinders.com […]

I think they make a ton of sense. My only problem with these products is the price if you only need them for one build, and then they sit around taking up space thereafter. Some of us do not have cherry pickers handy either, and to rent or borrow one is costly or a hassle so P Ayr’s products are great. If they could/would build some products of cheaper foam, etc. that would last only for the one the one build, and then you could toss it, that would be perfect for me.

I didn’t think they would be cheap, but atleast have the “basic cost” of a common used block so I could get an idea. Like my late dad use to say, Invest your time, before you invest your money.

Wayne you really came through with enough photos to clearly illustrate the many advantages of using the P-Ayr mock up components. But the highly informative text does a great job of explaining HOW to properly use the mock up pieces during each phase of the build process. Some automotive journalist only include a few lines of text describing WHY potential buyers might benefit from purchasing the product. It’s not even a good sales pitch.

Mock-up parts are rarely given the credit that they deserve despite being very useful tools. People would rather read about the latest fancy torque wrenches or how much additional horsepower can be gained by using chrome rocker covers on another tired junkyard LS engine.

This article opened my eyes to the possible advantages of using mock up parts and avoiding installation problems with the engine I have built for my ‘70 Mustang Mach 1. It’s a 351 Cleveland which normally wouldn’t be a problem because the car was produced with an “M” code Cleveland 4-V engine.

My Cleveland build is very similar to the engines that dominated Pro Stock during the seventies. They used production Iron 4-V quench chamber heads with extensive modifications done mainly on the exhaust side by milling off 1.4” of the exhaust ports and installing a thick piece of aluminum bar stock with substantially raised exhaust ports.

This “high port” conversion eliminates the power robbing sharp turn in the production ports by giving the exhaust charge a straight shot from the valve to the port exit. The intake ports are also given the high port treatment by filling the port floor with an aluminum insert, raising the port roof and increasing the port width slightly which makes the port shape almost square in comparison to the taller oval shape of the production port.

My high port conversion was professionally done by Endyn Inc. and have several more unique features that I won’t get into here. I wanted to convey the point about how much the exhaust ports have been raised and how it would be beneficial to do a mock up to determine if the shock towers need to be altered for enough clearance to fit headers designed specifically for the high port iron Cleveland heads.

I have a new set of Hooker Super Competition full length headers designed for the Cleveland in a 1970 Mustang chassis. They have 1.875” diameter primary tubes that are 36” long and merge into a 3.500” collector. Unfortunately I don’t think they will fit with the raised exhaust ports. The only way to make sure is to do a mock up test fit.

Hopefully P-Ayr makes Cleveland mock up components.

Daniel,

I’m sorry but P-Ayr Products does not have the Cleveland engine we have the Windsor but I know that does not do you any good

We are coming out with some new products in the next few months but the are all the new stuff

People are looking to putting the new modern drive trains in the older cars and trucks

Thank you for looking at our products and keep an eye on our web page for new items http://www.mockupmotors.com

HI, BEEN LOOKING FOR A USED OR LOW PRICED BLOCK. I’M 78 AND MY HAY DAY IS OVER. CRIPPLED UP WITH A STRONG IMAGANITON AND WONDERING ABOUT A V/8 ENGINE HANGING FROM MY CEILING IN MY MAN CAVE.NEVER QUIT DREAMING. THANKS JIM

Hi.. came across your site while trying to find a foam mock engine.. I don’t suppose you do bike motors.. looking for a CBR 1100xx blackbird mock up.. would be so much easier plus I can get started on the build whilst the donor bike is still complete an getting engine work done.. thanks..

Hey Gary, P-Ayr does make an American V-Twin mock up motorcycle motor (Harley EVO to be exact), along with transmission and related parts, but nothing for metric bikes.