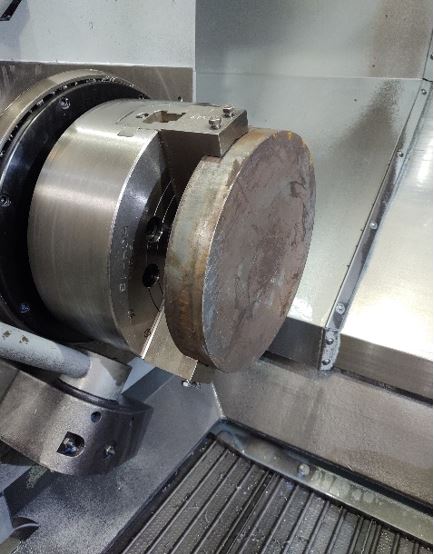

Chances are you don’t give much thought to that metal disc spinning inside of your bellhousing. However, choosing the best flywheel for your vehicle application will greatly affect performance, drivability, and your vehicle’s safety.

Flywheels come in several materials, including cast iron (gray and nodular), billet steel, billet aluminum, and chromoly.

Flywheel materials vary by both cost and strength. Your specific vehicle and application should dictate which you choose.

A flywheel has several jobs.

- It mounts directly to the engine’s crankshaft and has a machined surface to engage with the clutch disc which is sandwiched between the flywheel and clutch pressure plate, providing the critical element for transmitting power to a manual transmission.

- The flywheel also transfers inertia to the drivetrain, which helps get the vehicle moving from a stop as the clutch is engaged.

- Additionally, the flywheel has a ring gear around its perimeter, which engages the starter drive gear, and on externally balanced engines, the flywheel contributes to engine rotating assembly balance.

NOTE: The flywheel experts we consulted at Centerforce recommend replacing your flywheel fasteners when installing a new flywheel because your bolt strength should match or exceed the material strength of the flywheel.

How Flywheel Weight Affects Engine Performance

The best flywheel to choose will depend on your engine torque, vehicle weight, gearing, and intended purpose.

Choosing the proper weight is crucial in enhancing your driving experience.

Here are the average weights for flywheel materials commonly used on V8 engines:

Standard Weight Flywheel Materials

- Iron flywheels (Cast iron, Cast grey, Nodular) – 25-40 pounds

- Billet steel flywheels – 25-40 lbs.

Lightweight Flywheel Materials

- Chromoly flywheels – 14-21 lbs.

- Billet aluminum flywheels – 10-18 lbs.

Flywheels for four-cylinder and small-displacement six-cylinder applications may be lighter, as weight is related to flywheel diameter.

Standard-weight flywheels store more energy, and these flywheels are a good choice for helping to move stock-geared cars, and heavier vehicles like trucks, drag cars, rock crawlers, etc. Additionally, heavier flywheels slow throttle response and maintain engine rpm longer on deceleration, sometimes referred to as “hang time.”

A lightweight flywheel translates to faster engine response, on both acceleration and deceleration. They’re preferred for road racing and circle track because they allow the driver to drive deeper into turns with a sharper rpm drop as the driver lets off the throttle, then help the engine recover faster into its power band heading into the straightaway.

Turbocharged drag racers may prefer a lighter flywheel as well. Lightweight flywheels help to spool the turbo and can soften the launch with a high-torque engine.

Lighter flywheels can deliver the inertia of a heavier flywheel, but at increased rpm, requiring a slightly modified driving style to include more clutch slippage to get the vehicle moving.

The general rule of thumb is that the lighter the flywheel, the heavier the car will feel. There are exceptions, depending on the application.

…

Flywheel Material Recommendations by Application

| Cast Iron Flywheel | Nodular Iron Flywheel | Billet Steel Flywheel | Billet Aluminum or Lightweight Chromoly Flywheel | |

| Stock or OE Replacement | Yes | Yes | Yes, but excessive | Not recommended |

| High Performance Street | Not recommended | Yes | Yes | Yes, but conditional |

| Towing or Off-Road | Yes, but with limitations | Yes | Yes | Not recommended |

| Drag Racing | No | No | Yes | Yes, but conditional |

| Road Racing | No | No | Yes, but not optimum | Yes |

| Circle Track | No | No | Yes, but not optimum | Yes |

| Drifting | No | No | Yes | Yes |

…

Cast Iron Flywheels

Cast iron flywheels are cost-effective and used in many production vehicles.

They’re cast from proprietary iron, alloyed with a select blend of materials. After the casting has cooled, all surfaces and bolt holes are machined to specification, and then the flywheel is balanced. Cast flywheels are available in cast grey iron or nodular iron.

- Cast Grey Iron Flywheels: Cast grey iron (also called gray iron) contains flakes of graphite that develop during the cooling process. These flakes give grey iron a distinctive gray color when fractured, and they are also part of the alloy’s physical properties. Gray iron flywheels can be used as a stock replacement and in mild builds, but should never be associated with racing, high horsepower, sticky drag radial tires, or engines that operate beyond 6,000 rpm.

- Nodular Iron Flywheels: Nodular iron (also referred to ductile iron) is created by an alloying process that converts gray iron’s crack-promoting graphite flakes into spheres, or nodules. With this micro-structural transformation, the metal acquires superior ductile characteristics, with an outright advantage over gray iron in yield strength, elongation, and impact resistance. Nodular iron flywheels have been used as original equipment in an increasing number of applications, given the gains in modern engine horsepower and operating rpm. A nodular flywheel is an excellent—and cost-effective—choice for a high-performance street engine that’s limited in use.

…

Billet Steel Flywheels

The term billet doesn’t indicate the manufacturing process of the final product but refers to the material it’s conceived from.

Billet steel is a solid length of material that is formed in a blast furnace to remove impurities, then extruded into shape either by continuous casting or hot rolling. Billet is considerably stronger than iron and will remain free of stress cracks.

Billet flywheels are made from blanks sectioned away from portions of the larger bar (similar to slicing away a piece of bread), machined to specification, and then balanced. A final machining process removes stress areas from the metal, creating additional strength.

Billet steel flywheels are usually similar in weight to cast iron, and low-inertia versions are comparable in weight to chromoly (described below).

If you have a high-horsepower vehicle, tow heavy loads with your truck, regularly engage in high-performance driving, or drag race, a billet flywheel may be your best option.

The majority of billet flywheels are also SFI-1.1 certified for racing use. If your car’s 1/4-mile E.T. is faster 11.5 seconds, an SFI-1.1 spec flywheel is required, along with the proper SFI-rated bellhousing.

…

Billet Aluminum Flywheels

Like billet steel, billet aluminum is formed through continuous casting or hot rolling, and billet aluminum flywheels are also machined from blanks.

Aluminum isn’t hard enough to withstand the friction of a clutch disc.

To address this, a heat-treated steel friction insert is secured by screws or rivets to the flywheel. These inserts are replaceable, but riveted ones must sometimes be sent back to the manufacturer for resurfacing.

Additionally, many billet aluminum flywheels feature mechanically retained steel starter ring gears, due to the difference in expansion rate between the metals.

As mentioned above, billet aluminum flywheels are an excellent choice for road racing, circle track, drag cars, and under the right circumstances, even street cars. The majority of billet aluminum flywheels are SFI-1.1 certified for use in racing.

…

Chromoly Flywheels

Chromoly is a type of alloy steel that gets its name from the words chromium and molybdenum, the two major alloying elements in chromoly.

These elements (along with other materials) are combined in liquid form, then cooled. After the annealing process is complete, the steel is again melted so that it can be poured into form and worked through rollers to achieve the desired thickness.

Chromoly is only marginally heavier than aluminum, and because of its increased strength, the final product can be machined thinner without affecting its overall durability.

The ring gear is an integral part of the chromoly flywheel, making it as strong as the flywheel.

These flywheels offer a very similar feel to billet aluminum or lightweight billet steel flywheels, providing improved engine response due to the reduced inertia.

Great to know. Thanks.

Thanks for the quickie in flywheel metallurgy, Dave. Most of my experience has been with flex plates and automatics. Now I know just exactly what I don’t know about flywheels. But it’s never too late to learn

What about dual mass flywheels and replacing an existing dual mass with a traditional flywheel. I have heard about possible transmission noise etc. with going to a traditional flywheel mostly with the factory transmission …. solutions? thoughts?

’96 corvette LT4

May I ask which material makes the most powerful and reliable flywheel? It is the brass one or the aluminum or the steel one?. I am likely to hire essayontime.com.au/write-my-essay-in-australia source to write me an essay about this. I have an aluminum flywheel in my car which I guess need to be changed now.

[…] 25 levels of resistance. This eddy current resistance with 25 levels is combined with a high-speed, high inertia flywheel, which provides fast, quiet workouts. Besides, it includes 4- user settings and 29 programs in this […]

Hi there My name is Mike and I have a 360 dodge that has been bored out 60 over. So I believe that is a 372 now. And what I’m looking for is how or what to do for the flywheel as I have a non balanced flywheel in it now it needs the weight added RM 531 and if I go that way will the bolts brake/shear? And or should I change the flywheel to the built steel. But how to pick the right one? For balance ?