I’ve been reading your posts/blogs/articles on tuning with a vacuum advance and it’s been very helpful. My combo is a 355 small-block Chevy, 10.7:1 compression, 23-degree Brodix 10x heads that flow 295 cfm at 0.700-inch lift on the intake and 235 cfm at 0.750-inch lift, Jesel rockers, Holley Strip Dominator intake, 750 Holley with Quick Fuel metering blocks, a large cap HEI with an ACCEL coil, and an MSD 6T box. The cam is a COMP 260/264 degrees duration at 0.050 with 0.645/0.630-inch lift on a 101 lobe center (cam is advanced 6 degrees). The initial timing is 24 degrees, with 34 total all in at 3,000 rpm using two very lightweight springs and heavy weights.

My wide-band O2 sensor says I’m running in the low 14’s to high 13’s with 12-14 inches of vacuum between 2,500-3,300 rpm on level road at a steady cruise. It idles happily at 1,000 rpm at seven inches of vacuum and makes great power.

Regardless of the vacuum advance can I use, the engine has what sounds like a misfire at part throttle cruise. As soon as I roll into the throttle, it smooths out as long as I’m accelerating so I assume the carb is moving to the main metering circuit. When I disconnect the vacuum advance, the misfire goes away. But from what I’ve read, it seems that vacuum advance is a good thing for part-throttle performance. I’ve come to the end of my knowledge on tuning and my frustration level is rising.

I have run the carb tune everywhere from 13.0 to 17.0 AFR at cruise. Nothing makes the misfire go away. It seems to happen any time the engine runs over 2,500 rpm. All of the guys in my circle are EFI guys and I’m the only one with a carb and a distributor. Can you point me in the right direction so I can show them an old guy can still make more power the old school way? — W.S.

…

Jeff Smith: This question required a couple of emails back and forth to finally dial in where this engine was troubled. This small-block is quite stout with compression, a big cam, serious Brodix heads, and a large, four-corner idle Holley carburetor.

As with most issues, it wasn’t just one problem. I have to admit that I missed an important clue that he gave me with the original question that, now looking back, was the most-critical piece of information.

The clue is buried in the question and it took time to figure it out.

Rather than keep you in suspense, the clue was when he mentioned that the engine was set with 24 degrees of initial timing.

Engines with very large camshafts (260 degrees at 0.050 is a big cam for the street) generally require more timing at idle compared to shorter duration camshafts. Engines with long duration camshafts also suffer from large overlap values that drastically reduce idle vacuum. Add to this increased exhaust dilution in the intake manifold from the substantial overlap and the result is an engine that wants more initial timing.

Most performance engines with this much cam will be happy with 15 to 18 degrees of initial timing. Likely the reason this engine has 24 degrees of timing is that idle vacuum increased with the additional timing.

In this case, the high initial timing was aggravated by a very quick mechanical advance curve, pumping an additional 10 degrees of timing into the engine by 3,000 rpm. When he attempted to add vacuum advance to this timing, the engine began to misfire because there was just too much timing in the engine at part throttle at low speeds.

He mentioned that he had read some of my previous tech stories on using vacuum advance at part throttle and decided to try it. Unfortunately, this engine didn’t need the additional timing at part throttle mainly due to its higher 10.7:1 compression ratio.

Too much timing will make the engine surge and misfire, and that can be misdiagnosed as an ignition problem. That’s where we started with the diagnostics on this issue.

Once we determined that the ignition system was working as intended, the owner mentioned that when he disconnected the vacuum advance, the misfire disappeared. That was the second clue.

Later, he noted that reducing idle speed below 1,000 rpm caused the engine to falter badly.

With two lightweight mechanical advance springs, it’s common to see the mechanical advance start as early as 800 rpm or lower.

So the first recommendation would be to reduce the initial timing from 24 degrees to 18. This would require increasing the mechanical advance from 10 to 16 degrees to maintain the same maximum of 34 degrees of total advance.

At the same time, my recommendation would be to remove one of the lightweight mechanical advance springs and replace it with a medium strong spring.

For example, the MSD chart for its weights and springs show that two light springs will start advancing timing as early as 500 rpm. That’s way too quick and directly affects the stability and accuracy of initial timing. Adding a medium or heavy spring will slow the mechanical advance rate. This combination should still add all the timing in at 3,000 rpm but will slow the rate at which it builds timing at low speeds.

It’s entirely possible that with those light springs, the engine really did not have 24 degrees of initial timing as it appeared because of the very quick advance affecting the accuracy of the initial advance setting.

With stiffer springs, this will prevent the mechanical advance from starting at idle and allow you to set the initial much more accurately. Once the initial timing is properly set at around 18 degrees with the heavier spring package, then the total timing can be rechecked.

Because of these changes, the engine will see less timing at part throttle around 2,500 rpm. This might be between 6 and 10 degrees.

This should create the situation where the engine will run much smoother at part throttle. Once this is established, then he can go back and attempt to add 4 to 6 degrees of vacuum advance and evaluate the change. It is possible that the engine may not want this additional timing. If so, he should consider that a positive.

The less timing the engine wants to run at part throttle means it is operating more efficiently and does not require additional timing to optimize the cylinder pressure. This is true in all situations from part throttle to WOT.

Hopefully these suggestions will make the engine run smoother and more efficiently.

And he learned all this at Iowa State aka John Deere school of Journalism. Home Town Boy Did Good

Hello. I have a question about intercoolers. I have found 2 different size cores to fit my car. 1 has bigger inlet and outlet pipes but is a smaller core. Which 1 would be better for more power and torque? I live in the UK so it’s hardly ever hot weather here. I drive a European Audi s3 2015.

The core sizes are 640x408x55mm with 70mm inlet and outlets. The other is 624x410x64 with 60mm inlet and outlets. Any help would be greatly appreciated. Many thanks

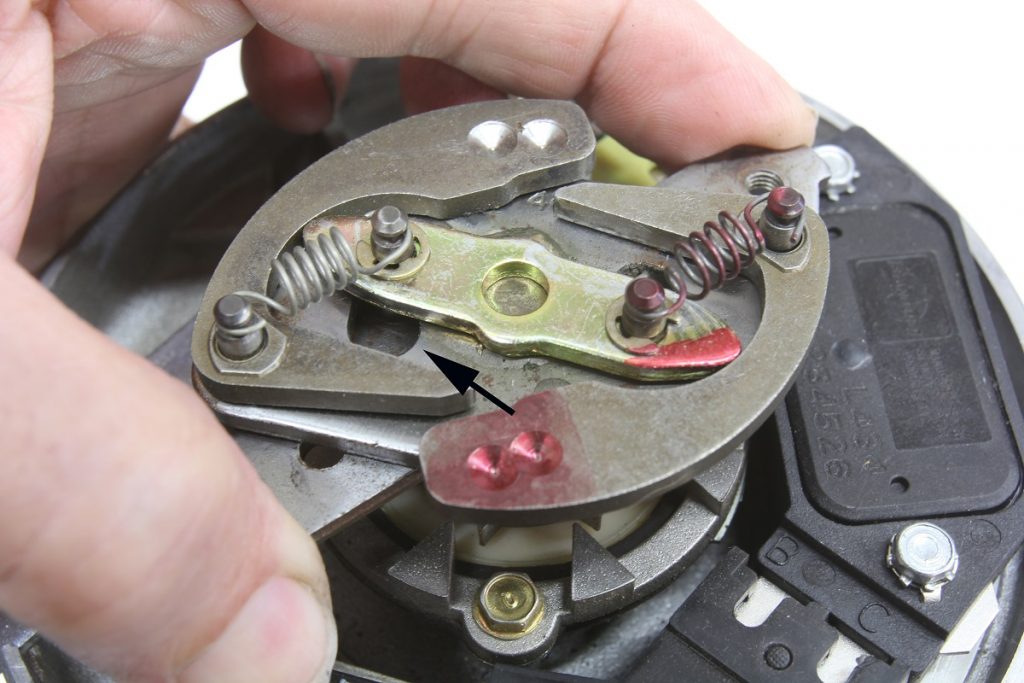

That distributor in the picture has a common problem of the wire breaking inside the insulation on the pickup coil, when the vacuum advance moves the wire separates losing connection. Unplug the sensor from the module put a ohm meter on it, use a vacuum pump to move the advance and see if you lose continuity

I am sure you got this guy fixed, but I have to tell you a little story about a problem I had. A customer came in with a Astro van, I road test for a misfire without doing anything else I figured from experience that it was the pick-up coil, replaced it same problem, then I went on to a major tuneup witch it needed badly, but I like to fix the original problem before I sell additional work, same problem. Make a long stay short after much headache and a whole day and lots of parts at my own expense and nowhere else to go I start over, replace the pick-up, problem gone, remember this is like 25 – 30 years ago, no fancy equipment for us side street guys. Bad pick-up in the A/c Delco box.

I had the same problem with the same vehicle many moons ago. Did the same thing and started the pickup and the problem was solved. It was a delivery van, and the customer needed it to keep his job. Good thing the customer waited the whole time.

I have seen this before too low speed misfire

From too much initial and typical vacuum can with 20* advance

I alway limit the vacuum can to 10-11* of total advance ( weld a tab on slot or make a big bushing ).

Hello Jeff. I have been reading your articles for along time. After reading this one I am questioning one of my choices. I am restomoding my 66 matching numbers L-78 chevelle and am wondering if I’ve chosen the wrong distributor. The combo is the original 396 .030, 10.5 compression, iron heads, .540/.560 lift flat tapped hydraulic cam with .230/.240 @ .050 duration. It’s a 4 speed with 373 gears. The car will see 80% street driving. I chose an Msd pro billet distributor with only mechanical advance. Would I be better off with vacuum advance as well? Thanks

In discussing the guy with 24 degrees advance and a misfire, it sounds like he was running ported vacuum, or to say it another way, above the butterflies.He seemed to know where to check vacuum values, do you recommend ever using

Ported vacuum with a high performance engine?

Would the best initial timing occur at the highest vacuum reading ? Putting a firmer spring in one side is good advice. Should you then run manifold vacuum to vacuum advance to smooth out idle. Always wondered if you could plot your distributor advance curve with a vacuum gage