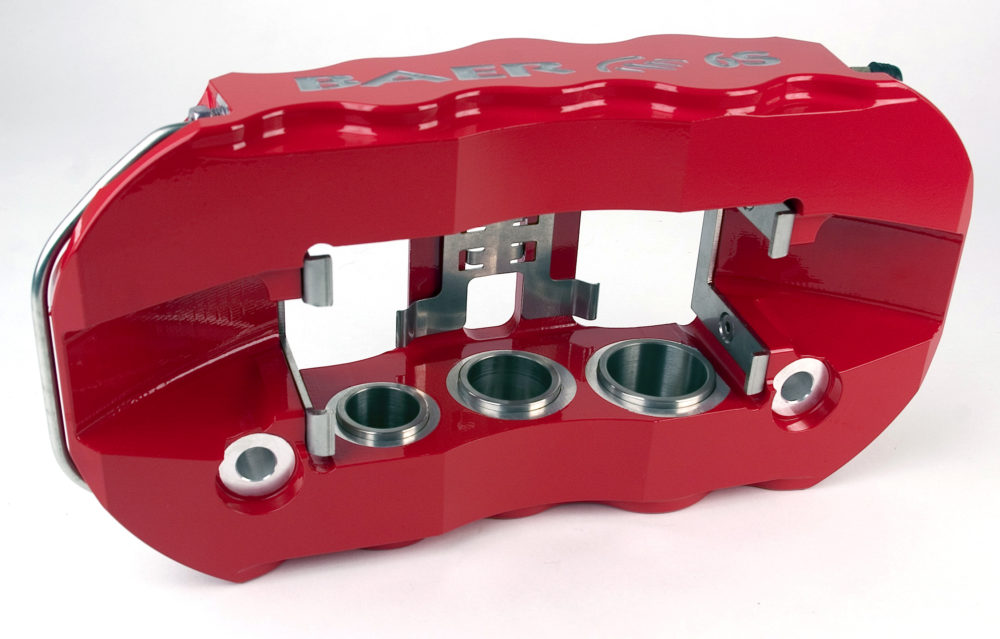

This is a Baer six-piston caliper. With this caliper, you would calculate the caliper piston area the same way as a four-piston except multiply the area by three instead of two. Larger calipers with more pistons apply load to the brake pad over a greater area of the pad, improving performance. (Image/Baer)

I have a ’64 El Camino that has been converted to front discs using 1970 Chevelle parts. I was told that I should change the master cylinder as well, so I bought a dual reservoir power brake master thinking that would be better, even though my car does not have the power brake booster. I installed the master and while the pedal feels super solid, I have to almost break my leg on the brake pedal to get the car to stop. I know this isn’t right, but I’m not sure what I did wrong. Can you help?

J.R.

It sounds like you used either a 1 1/8-inch or 1-inch power brake master cylinder. The short answer to your question is that as the master cylinder piston diameter becomes larger, it moves more fluid for the same travel of the piston, but creates less pressure. This pressure is multiplied by the front brake caliper pistons to create clamp load on the rotor. So for the same amount of pedal effort, a larger piston will generate less pressure and that’s why the car does not want to stop even with a ton of brake pedal effort.

One solution is to add a power brake booster. This will add to the brake pedal effort and probably solve the problem. But assuming you don’t want to add a power booster, then a smaller master cylinder piston diameter of 7/8-inch or possibly 15/16-inch will help this problem. Going from a 1 1/8-inch master to a 7/8-inch version is a major change.

That’s the quick and easy answer—but if you are a regular reader of this column, you probably know that we don’t just stop at the quick and easy answer. The best way to prove this point is with a little simple math. I know, math is rarely simple—but in this case we will really try to make it easy to follow.

So let’s start with the application of load on the brake pedal. We’ll use a nominal or medium effort on the brake pedal of 75 pounds of force. We will also assume that the brake pedal has a pedal ratio of 6:1. This is not true with all cars, but for older cars like the ’64 El Camino, that’s a safe number for a non-power assist car. The pedal ratio multiplies the effort you put on the brake pedal by the ratio, so for 6:1, this means 75 pounds of force on the pedal is multiplied to 450 pounds (6 x 75 = 450) pushing on the master cylinder piston.

To get brake line pressure—we first must determine the area of the piston. If you remember from high school geometry (c’mon it wasn’t that long ago!) the formula for the area of a circle is Area = Pi x Radius x Radius, or Pi(r²). So if we have a 1-inch master cylinder, this creates a piston area of 3.1416 (Pi) x 0.5 x 0.5 = 0.7854 square inches.

To determine the pressure created by the master cylinder, we divide the pedal force applied to the piston (450 pounds) by the piston area:

Pressure = 450 / 0.7854

Pressure = 572.9 psi (rounded to 573 psi)

Now we need to see just how much clamp load this master cylinder pressure will create.

But first we need to know the caliper piston area because it affects the force applied to the pads and brake rotor.

For the typical single piston floating caliper, that piston is 2.93 inches in diameter. We’ll use the same formula to compute the area at 6.74 square inches. This we can multiply by the master cylinder pressure of 573 psi to generate 3,863 pounds per square inch of load on disc brake pads. This is split between the two pads.

For the sake of explanation, let’s change the caliper to a fixed four-piston caliper. For opposing piston calipers, we only use one side for the calculation, so in this case we will find the area of the two pistons. Let’s also say these pistons are 1.5 inches in diameter. The area calculation is very similar to the one for the master cylinder except we multiply that area times the number of pistons.

Math Formula for Fixed Four-Piston Caliper

Caliper Piston Area = Pi x Piston Radius x Piston Radius x Number of Caliper Pistons on One Side

[Note: We are multiplying Pi by the piston radius twice, or as mathematicians say, the piston radius squared. (Example – 0.75²)]

Caliper Piston Area = 3.1416 x 0.75 x 0.75 x 2

Caliper Piston Area = 3.53 square inches (Note that the area of these two pistons isn’t as great as the single-piston caliper—but the single piston must split its force between two pads while the four-piston caliper applies this load on both sides.)

Next, we multiply the master cylinder pressure by the caliper piston area to come up with a total clamp load on the brake pads.

Clamp Load = Master Cylinder Pressure x Caliper Piston Area

Clamp Load = 573 psi x 3.53 square inches

Clamp Load = 2,022 pounds per square inch

If we divide the single piston caliper’s 3,863 by two pads, this is only 1,931 pounds of force per pad, which isn’t as much as the four-piston caliper per pad.

We’ll save you the math of going through this again with a smaller, 7/8-inch master cylinder.

With the same pedal effort, with the four-piston caliper package, this smaller master cylinder will create 2,640 psi at each brake pad, which is a solid 30 percent more clap load!

The trade-off is that the smaller master cylinder piston will require a slightly longer pedal stroke to move the same amount of fluid as the one-inch piston master. So the pedal will feel differently. We’ve had people tell us that this will feel like the pedal is spongy. Assuming that you’ve properly bled the system, what you are feeling is the longer pedal travel compared to the larger piston.

All this math is really just to reveal how much of a difference the master cylinder piston choice has on how the system operates. As a further example, you could add a power brake booster to your system, which effectively reduces the amount of pedal effort necessary to create the same amount of master cylinder line pressure. But boosters generally require a larger piston diameter. So there is more than one way to approach this issue. If you are not planning on adding a booster to the system, then a smaller master cylinder piston is usually a better way to go.

Hi, I think that your calculations on final pad pressure are off, because you don’t consider that there are two calipers on the front or rear of the car. If this article were written for a motorcycle, then it wouldn’t need changes. Also if you are using a dual manual MC setup (assume a simple 50/50 bias), the pedal effort is split across the combination of two MC pistons, which can be sized differently.

Yes Daniel, you are correct, I should have stated in the story that these calculations were for a single wheel.

I need some help I have a1978bford f600 dump truck it Factory had a hydrovac with the booster underneath the cab and a single Reservoir master cylinder on the firewall to help because the brakes were lousy at best we put a booster and master cylinder on the firewall off an F-350 which did help I would like to try to find something that would help the system be a much better brake system a hydroboost or an heiress is something of that nature any suggestions it has two wheel cylinders per wheel I believe the rear ones are inch and a front 15/16 I think the master cylinder I have on now I think is an inch and a quarter or an inch and a half I’d have to double-check it has quarter inch brake line I thought about changing the brake line to 3/16 to help if it would

Jeff;

I want to replace the single master cylinder and hydrovac on my 56 6400 2 ton truck, with a dual master cylinder and vacuum booster. It is all drum brakes. Got any suggestions?

Hi Jeff,

Got a question about pistons area vs pad area.

Which is more important and increase brake performance?

BBK1 pistons area is bigger but pad area is smaller.

BBK2 is the opposite.

Thank you.

Hey Jeff I have a doozy for you. I have a 1963 biscayne. I and converting it to Ctsv brembo brakes. I am making my own front caliper brackets. I am installing a Versailles 9” were I have removed the factory disk brakes. I am installing GT 500 rear rotors do to the similar rotor diameter. And also singing the Ctsv rotors and making my own brackets. The fab work is coming along nicely. My question is about the brake booster and master cylinder. I don’t have a clue on that aspect. I’d like to hide all that under the dash and out of the engine bay. Any suggestions on calculating what booster and master cylinder I’ll need.