Volumetric efficiency is a term that’s tossed around quite a bit when talking about internal combustion engines. However, surprisingly few people understand what volumetric efficiency is and how it actually affects engine performance.

In this post, we’ll discuss volumetric efficiency, provide the volumetric efficiency formula, and show some examples of how it applies to specific engine examples.

What is Volumetric Efficiency?

Volumetric efficiency (VE) is the actual amount of air flowing through an engine, compared to its theoretical maximum. Basically, it is a measure of how full the cylinders are.

VE is expressed as a percentage. An engine operating at 100 percent VE means we’ve trapped 100 percent of the air a cylinder can theoretically hold by mass. Volume always measures the same, but restrictions lighten the mass of air/fuel compared to what a cylinder theoretically holds. Inertial tuning of the intake, heads, cam, and exhaust can make the volume heavier. The heavier it is, the more air/fuel it contains that can be burned to make power.

How is it calculated?

The Formula for Volumetric Efficiency Is:

VE = (CFM X 3,456) / (CID X RPM)

In this formula, CFM is the amount of air (in cubic feet-per-minute) being pumped through the engine. This is NOT the CFM rating of the carburetor. This can be difficult to measure and requires special testing equipment.

How Does Volumetric Efficiency Affect Performance?

Volumetric efficiency can be a tricky topic. Air density changes with temperature and altitude. Therefore, VE can change based on the environment.

At sea level, the air is more dense. This means that there are more air molecules inside the cylinder. In the mountains, the opposite is true. The same engine would operate at a higher VE at sea level than in the mountains.

You can improve VE by making it easier for air to flow. This is the idea behind aftermarket intake manifolds, cold air kits, porting and polishing cylinder heads, and headers. Pumping more air is also the idea behind superchargers, turbos, and nitrous. These power adders force more air into the cylinder. When the fuel and ignition systems are properly tuned, this can raise VE over 100 percent and make tons of power.

The chart below gives some general VE ratings for different types of engines:

|

Engine Type |

VE% |

|

Modern Stock Engine |

85% |

|

Slightly Modified Engine* |

100% |

|

Highly Modified Engine** |

115% |

*Slightly Modified = performance cam, ported stock cylinder heads, performance intake manifold, headers, ignition upgrade

**Highly Modified = aggressive cam, performance intake manifold, headers, ignition upgrade, aftermarket configuration racing cylinder heads, 14:1 or higher compression ratio

How Volumetric Efficiency Relates to Your Engine’s Dyno Curve

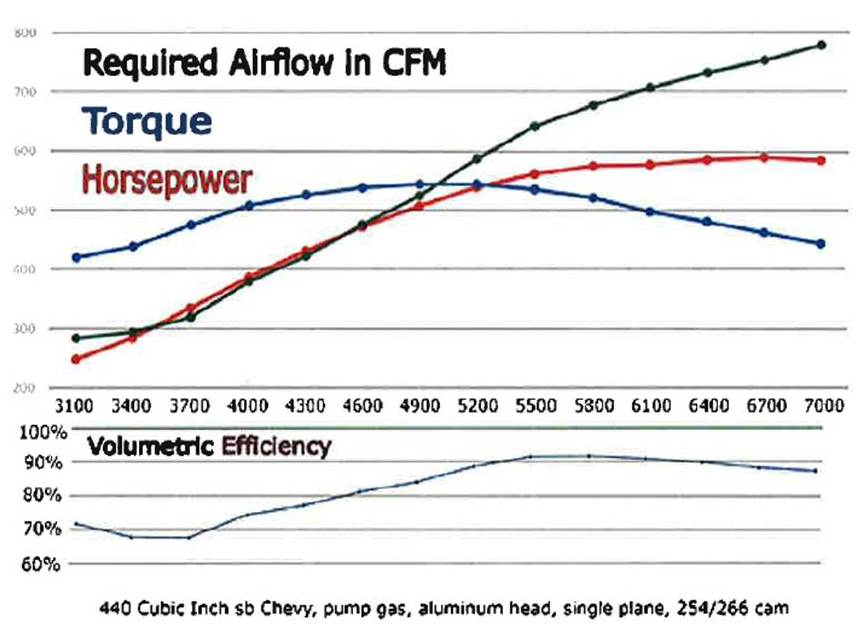

VE is based on an engine’s horsepower dyno curve. The example in the graph below is a naturally aspirated 440 cubic-inch engine. We know it makes 592 horsepower and we know it makes it at 6,700 rpm.

Formula to estimate VE at different rpm from an engine’s dyno curve:

horsepower x 4235 / CID x rpm = VE

592 x 4,235 = 2,507,120

440 x 6,700 = 2,948,000

2,507,120 / 2,948,000 = .85 percent VE

Note that the engine peaked at 92 percent VE between 5,500 and 5,800 rpm—after peak torque began to fall. This number isn’t helpful in the carb cfm calculator, but is a good measure of performance. However, since we now know this engine has an 85 percent VE slightly below redline, we could use it to determine carb cfm rating using the standard cfm formula:

CID x redline rpm x VE /3,456

440 x 7,000 x .85 = 2,681,000

2,681,000/3456 = 757 cfm

A 750 cfm carb would be the smallest and generally most responsive that meets the horsepower peak airflow requirements. An engine wastes increasing amounts of air past peak power, so a slightly larger carb might be a benefit in a pure race engine.

[…] it makes it at 6,700 rpm. ——————– More in the article accessible from this link: Learn About Volumetric Efficiency and How it Affects Engine Performance Damocles is online now Quote Quick […]

[…] Fun Fact: The volume of air/fuel mixture trapped in the cylinder is always the same whether the engine is at idle or 9,000 rpm WOT. At part throttle, it’s less dense. At WOT, it’s more. Check out this article explaining volumetric efficiency. […]

Thankyou for the formula’s. I have been pondering the development of a et/bracket s-10 using a 358 C.I. Chevrolet and the formula’s gave me the following. If my engine made 600 H.p. at 7000 rpm its VE would equal 1.01% at 7000. if I did this right this would be able to be done with a Holley 750 cfm double pumper. What do you think?

I enjoyed reading this. I am puzzled by the number 4235 in the VE calculation. As that is a constant can you explain where 4235 comes from. I’m normally able to reason it out, but in this case it just isn’t happening. Thank you for your time.

So 4235 in the VE calculation considers the engine horsepower dyno curve. That stands to reason. Law of diminishing returns.

[…] air filters, and intercoolers. The volumetric efficiency of an engine is an important factor. A higher VE engine requires much less intake manifold pressure (boost pressure) for the same compressor mass flow as a […]

Hi, I have a couple questions.

If I’m using a head that’s advertised as flowing a given cfm, would there be a correction factor to apply for altitude that reflects its true flow?

Also, when calculating horsepower loss at high altitudes, should you use the theoretical, physical atmospheric pressure at your altitude, or a corrected air density calculation according to weather factors? My local altitude is about 5000′, but on a hot day the DA will be in the 9000′ range.

Thanks!

Vince

There are some important details missing. Firstly, can you edit the article to say where the “magic numbers” 3,456 and 4,235 come from? I assume they are just scaling constants, but it’s valuable to say that and maybe link to a source, or explain them in a footnote. In the graph, where does the “required airflow” curve come from? Is it a theoretical number based on an assumed net engine efficiency? If so, it’s again important to say so, and state what the assumed engine efficiency is (which will vary across the engine speed range). Again, a link to source material would be very valuable.

3456 is just 1728 times 2 … one cycle is half of the rpm because camshaft rotation is half the crankshaft … so to go from cubic inches to cubic feet is 12 x 12 x 12 or 1728 then times 2 to cut rpm by half or 3456 …

4235 is the inverse of .0002361 … that number is based on cfm demand of a engine or 1.01055÷640÷ 2 x 1.15 ….. that formula is conversion to 28 inches of water on a flow bench …. air speed in fps …2 is rpm in half and 1.15 is volumetric efficiency …then he multiplied by .26 which is cfm to hp …. that comes out to .0002361 you then devide that into 1 to get 4235 ….

This is not good math … I did a video on cfm demand and talked about this … its on YouTube under my name