If I’m using timing control on my FiTech EFI, why do I need to buy the adjustable MSD rotor? Can’t I just lock out the distributor and then ensure the rotor aligns with the Number 1 spark plug terminal and make final adjustments to sync timing with the ECU using a timing light? Or, could I wire a stock GM small cap HEI to do the same?

C.C.

Jeff Smith: I edited out the part of your question that began with “this is a dumb question,” because your question shows you really have a solid handle on what’s going on with EFI and electronic control over the ignition. The simple answer to your last question about the small-cap HEI is – yes. That’s where most tech writers would stop, but frankly with that answer we haven’t really learned anything. Let’s pry open this slice of investigative technical journalism and trace it back to the real issue – rotor phasing.

Your initial question regarded the adjustable MSD rotor. MSD originally created this product to allow moving the rotor to keep it near the spark plug terminal on the cap. This adjustable rotor was used mainly in conjunction with a crank trigger ignition. With fuel injection and electronic control over the ignition, the ignition timing can easily move from roughly 10 degrees before top dead center (BTDC) to as much as 50 degrees BTDC under light load cruising situations. Using these numbers, the rotor sweep is a full 40 degrees. The idea is at idle, to place the rotor effectively perhaps 15 degrees “retarded” relative to the spark plug terminal. Then as timing is advanced, the rotor will sweep across the spark plug terminal to roughly 25 degrees on the other side of the terminal.

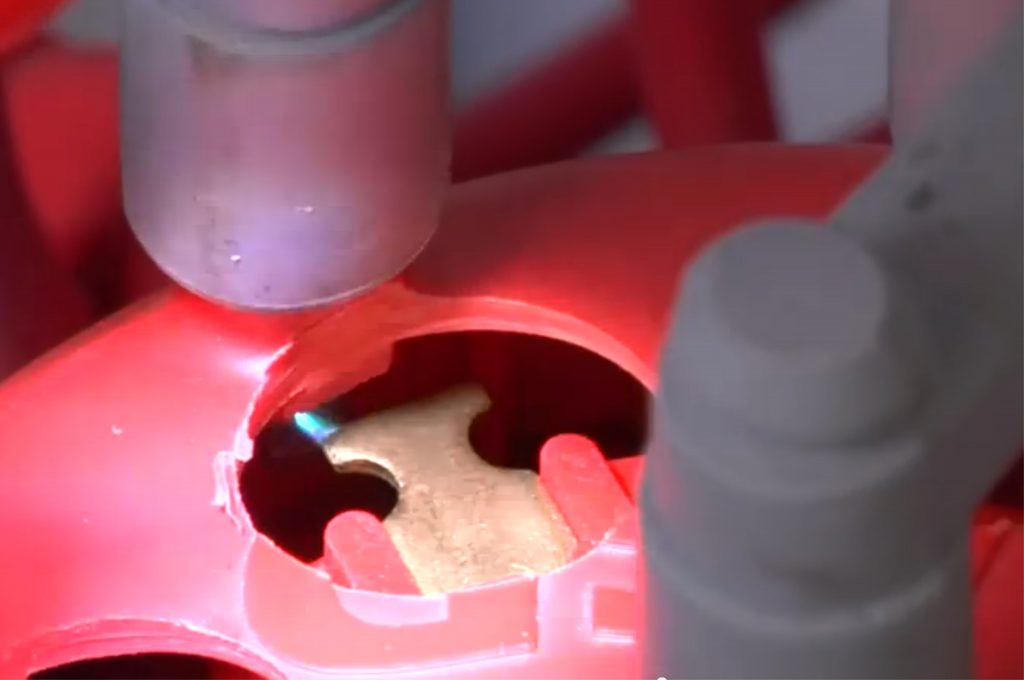

This is an MSD photo of a rotor that is not phased properly.

Note how far the spark has to travel to reach the spark plug terminal on the distributor cap.

This keeps the rotor physically close to the terminal in the distributor cap, which shortens the distance the spark must travel between the rotor and the terminal and into the spark plug wire. If you think about this in terms of degrees of distance between each terminal (with 360 degrees in a circle and 8 terminals), that means there’s only 45 degrees between each terminal on the cap. That should help put this into perspective.

With electronic ignition timing control, there is no need for a mechanical advance mechanism in the distributor. That’s why all the aftermarket EFI installations require a locked distributor. You can easily do this with an MSD distributor by disassembling it and moving the advance pin in the mechanism 180 degrees from the slot into a drilled hole. This locks the rotor in place. Then the MSD adjustable rotor is required to phase the rotor to create the proper sweep.

Several companies like Accel, FAST, and Holley offer what is called a Dual Sync distributor. These are designed to be used with EFI because the rotor has been “pre-phased.” To explain how this works, we have to go into how the system triggers the ignition. In a traditional ignition system, when the trigger wheel on the distributor shaft aligns with the magnetic pickup, this triggers the ignition system to fire the coil. Mechanical and vacuum advance systems advance the position of the trigger wheel to create more ignition advance.

With a properly phased rotor, note how close the rotor is to the spark plug

terminal – requiring less voltage from the coil and far superior engine performance.

With an EFI system, the trigger wheel is locked in a fixed position. In order to make this system work, the usual approach is to pre-set the ignition trigger at an advance that is more than what the engine would use – like 50 degrees BTDC. The pickup and trigger are set at that point and then the ECU delays the ignition it to the actual timing the engine requires. So the trigger signals an event at 50 degrees BTDC, but the EFI controller delays this to the appropriate timing such as 30 degrees BTDC as determined by the spark map.

Here’s where the issue lies. On most traditional distributors, the rotor is phased to line up directly with the distributor cap terminal when the trigger wheel aligns with the magnetic pickup. Now if we align the pickup and trigger wheel at 50 degrees BTDC, the rotor is pointed well away from its intended spark plug terminal. So this requires us to “phase” the rotor. With most distributors, we will need an adjustable rotor that will allow us to position the rotor so that it sweeps across the terminal and minimizes the distance away from the terminal.

This 50-degree figure is most often used as the pre-position for the ignition because it allows us to work toward making sure the rotor is very close to the spark plug terminal at the rpm where peak torque occurs. This is important because peak torque occurs because the engine is making maximum cylinder pressure. Higher cylinder pressure also demands higher ignition voltage to push the spark current across the plug gap. Reducing the rotor gap reduces this overall voltage. It’s a somewhat complex relationship, but you can see why all this is important.

We’ve included a couple of photos pulled from an MSD video that shows the relationship of the rotor to the distributor cap terminal both when the rotor is accurately located and also when it is too far away. You can see how the spark has to travel a much greater distance when the rotor is not phased properly.

We were faced with a similar issue a few years back when we wanted to run an MSD electronically-controlled box that would allow us to digitally control the timing curve on a small or big block Chevy. As with any EFI system, the requirement was to run a locked-out distributor. We were looking for a way to do this when we realized – as you have – that GM did this first with a large cap HEI distributor and then later changed to a small-cap fixed rotor distributor with a separate coil as used on both the truck throttle body applications and the TPI Camaro and Corvette engines.

We did a quick test of this little unit and realized that the GM engineers designed this small-cap distributor with a pre-phased rotor. We lined up the rotor with the distributor cap and then reversed the engine until the trigger wheel lined up with pickup. This placed the rotor roughly 20 degrees “retarded” relative to the distributor cap terminal. This means that with roughly 45 degrees of total advance at part throttle, the rotor would swing from 20 degrees “behind” the terminal to 25 degrees “ahead”, minimizing the distance the rotor is from the spark plug terminal. This distributor is essentially “pre-phased” from the factory.

What is even better is that the GM pickup is virtually identical to the magnetic pickup used in the both the MSD and most aftermarket distributors. So we removed the module from a used small-cap distributor and clipped off the factory connector. MSD sells a replacement two-wire connector plug that we used. The wires coming off the GM pickup are green and yellow. The MSD colors are purple and green. Simply connect the green to green and yellow to purple, and you now have a locked out small or big block Chevy distributor with a phased rotor.

We made a simple little aluminum plate to take up the space created when we removed the TPI module and used the rubber grommet to protect the wires. The beauty of this simple conversion is that our distributor uses the stock pickup, distributor cap, and rotor from an ‘80s TPI engine that are available from any auto parts store so you don’t need to carry unique distributor cap or rotor spares.

Hope this helps with your understanding of rotor phasing.

My car has the FiTech EFI but I did not put it in so how do I know if the FiTech is controlling the rotor? My distributor still has a vacuum advance hooked up.

The fitech would only be controlling the timing if you have a locked 2wire distributor. Your fitech would also be set to VRCOIL instead of TACH. If your using the blue rpm wire going to the tach output on your distributor. The fitech is not controlling timing.

The “base” 400HP FiTech units don’t control timing – and that’s probably what you have. In that case, you leave the dizzy alone – and let the existing mechanical and vacuum advance control the timing. If you don’t have a two wire timing pickup harness running from the FiTech to the dizzy, then you aren’t controlling timing. The 600HP systems do control timing – there’s a two wire timing pickup harness from the dizzy to the EFI and a timing control wire from the EFI to the Coil Negative terminal.

[…] the spark phasing and ensure it really is phased. I got (aka stole) the idea from this write up. Ask Away! with Jeff Smith: Rotor Phasing and How it Relates to Aftermarket EFI Systems – OnAllCylind… 1968 Skylark Convertible 383 Stroker, Turbo 350, 3.73 Posi FiTech GoEFI4 600 RobbMC […]

[…] Units supporting up to 600-800 horsepower can be found between $1,000-$1,250. They offer color touch screens for initial programming. Some models have air/fuel ratio compensation and timing retard for mild boost and wet nitrous. Data logging, multiple fan control and AC idle control are options at this price point. Ignition timing control is possible with a two-wire distributor with a properly phased locked out rotor. […]

[…] control using the above dist? if not link is below with links to parts used from summit racing. Ask Away! with Jeff Smith: Rotor Phasing and How it Relates to Aftermarket EFI Systems – OnAllCylind… A) MSD HEI bypass module cable. part # 8861 https://www.summitracing.com/parts/msd-8861 B) […]

[…] is. Here is the write up about this distributor and how to set it up to run with these systems. Ask Away! with Jeff Smith: Rotor Phasing and How it Relates to Aftermarket EFI Systems – OnAllCylind… A) MSD HEI bypass module cable. part # 8861 https://www.summitracing.com/parts/msd-8861 B) […]

well jeff, as usual you never cease to amaze me. doing a small block s10 swap and have decided to go fitech for a bunch of reasons. was looking for an answer to the timing control question and ran across this. have been a g m tech for the last 30 years and the answer was right in front of me. love the harness and aluminum block. wow.thanks bud, just saved a bundle of time and cash on this question.will do as advised, got a lot of time with these units over the years and am not a racer but for street use this looks like a winner. and its compact as well. thanks again

Darrell

I’m glad this worked out for you as it really is a high quality conversion that is very inexpensive.

Hi Jeff, I know this is an old article, but I’ve been playing around with using vacuum advance along with ECU timing control. I’m setting the spark map in my FiTech system to replicate a mechanical advance curve and letting the vacuum advance do what it always has, account for the load changes.

The reason I’m writing is because I was told by many folks this would not work because the rotor/trigger is locked to the engine when the distributor is locked. The words they used matched the comment you make in this article, “Mechanical and vacuum advance systems advance the position of the trigger wheel to create more ignition advance.” Actually, at least for my SBC and the MSD 8361, the vacuum advance retards the plate that holds the pickup, thus advancing when the trigger reaches it.

I’ve only been playing with this for a day, but I really like what I’m experiencing. With the small spark table in the FiTech, I can easily replicate the mechanical advance. Anyway, because I received such strong pushback that it wouldn’t work, I thought I would pass this on. Here is a link to where I posted what I did and why: https://www.chevelles.com/forums/89-efi/1089676-using-vacuum-advance-ecu-managed-timing-2.html.

BTW, I’m a huge fan of your writing, I really enjoy the simplicity with which you explain some complex issues. You won’t remember, but I rode with you in an elevator a long time ago in Las Vegas. You were wearing something car related so I struck up a conversation about converting my 67 Camaro to electronic ignition…I remember wishing the elevator ride was much longer because the discussion was great! We introduced ourselves, but it wasn’t till much later that I realized who I had been talking with. Thank you for the discussion then (yes I converted!) and for all the great articles you’ve written.

Ok, I understand this but what I’ve done instead of an adjustable rotor is made the magnetic pick-up adjustable so I can phase it with the rotor, same thing just in reverse of which parts are adjustable. I have not as yet finished it as I blew the coil driver apparently when I hooked it up backwards at the battery and the pick up.

Hi I’m looking at doing small cap hei on sniper efi on a sbc what refrance angle would you install at?

And inductive delay?

And I take it rotor won’t need phasing?

Cheers jeff

Hi Jeff,

Thanks for the explanation.

Seems no one can answer my question

Am going to switch to electronic timing.

My question is: have near new pertronics heiIII module & matching race coil in large hei dist.

Also have new gm performance large hei distributer.

Intent is keep these parts and lockout the large hei by drilling advance mechanism & using a kit from Speedway motors to lock the vacuum advance plate, this kit makes it manually adjustable.

Will this work???

Hi Jeff,

I’m one of those doing a Sniper EFI, and if I read the above article correctly, the stock small cap EFI distributor is phased at 45*. Is this correct? The Sniper setup requires the distributor phase angle, and I’d like to put the correct value in there.

thanks,

Corey

Hi,

What was the last year GM made a s15 without ANY computer parts? I’ve searched the net for 30 minutes…no answer, seems like a simple question, hard to find the answer…so I figure you’ll know the first year they went to EFI & I’m assuming thats when the computer BS got involved…

Thanks for your answer in advance…cheers