When you think of an automotive cooling system, the first thing that likely comes to mind is your radiator…or maybe your cooling fan. The oft-overlooked fan clutch doesn’t get a ton of credit or attention, but it’s an essential piece of the cooling equation in many vehicles. It helps your cooling system operate effectively and your engine operate efficiently.

But let’s start at the beginning.

What is a Fan Clutch?

A fan clutch is a temperature-controlled coupling between the water pump shaft and the fan which allows the fan to be operational at low speeds and disconnected at higher speeds. This allows the engine to operate more efficiently by removing the load that the fan places on it.

So how does it work?

It really depends on the style of fan clutch you choose.

Types of Fan Clutches

The main types are non-thermal, thermal, and electronic — all of which use a silicone fluid to engage and disengage your fan.

Non-Thermal Fan Clutches

Non-thermal clutches operate solely based on the shaft speed of the water pump. At low and idling speeds, the clutch allows the fan blade to turn at almost a 1:1 ratio. At high speeds, the silicone fluid within in the clutch will lose its ability to transfer the energy from the shaft to the fan clutch body (and therefore, the fan) and the fan is then allowed to almost free-wheel, removing its load from the engine.

Non-thermal clutches operate solely based on the shaft speed of the water pump. At low and idling speeds, the clutch allows the fan blade to turn at almost a 1:1 ratio. At high speeds, the silicone fluid within in the clutch will lose its ability to transfer the energy from the shaft to the fan clutch body (and therefore, the fan) and the fan is then allowed to almost free-wheel, removing its load from the engine.

A non-thermal clutch provides a steady flow of cooling air but is always engaged, so it offers lower fuel savings than a thermal-style fan clutch. However, non-thermal clutches are a lower-cost option than thermal-style clutches.

Thermal Fan Clutches

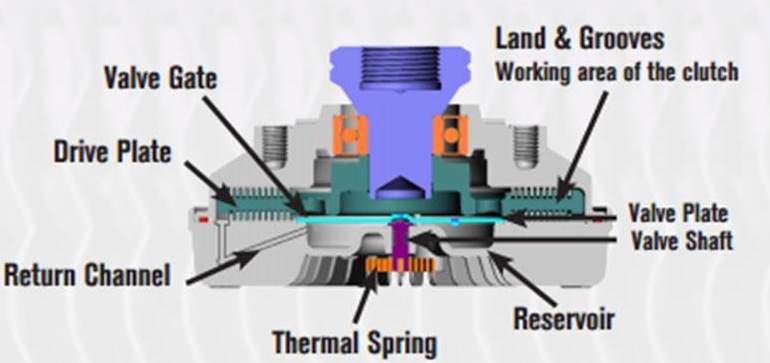

The thermal fan clutch operates in response to underhood temperatures. As hot air blows across the radiator, it heats a thermal spring mounted at the front of the clutch. As the spring is heated, it turns and allows valve ports to open within the clutch. Silicone fluid stored inside a reservoir is allowed to pass through these open ports and enter the working area of the clutch. This engages the clutch and drives the fan. Once the engine is cooled down, the thermal spring rotates back and closes the valve ports, disengaging the fan.

The thermal fan clutch operates in response to underhood temperatures. As hot air blows across the radiator, it heats a thermal spring mounted at the front of the clutch. As the spring is heated, it turns and allows valve ports to open within the clutch. Silicone fluid stored inside a reservoir is allowed to pass through these open ports and enter the working area of the clutch. This engages the clutch and drives the fan. Once the engine is cooled down, the thermal spring rotates back and closes the valve ports, disengaging the fan.

The speed at which a thermal fan clutch spins a fan depends largely on the exact fan you choose. On the Summit Racing website, for example, you’ll find three different types of thermal fan clutches from Hayden alone:

Standard-Duty Thermal Fan Clutch: This design turns the fan at 60-70 percent of the water pump shaft speed when engaged, and 20-30 percent when disengaged. It’s made for fans with a lighter pitch.

Heavy-Duty Thermal Fan Clutch: This fan style turns the fan at 70-90 percent of the shaft speed when engaged for increased cooling. When disengaged, it turns the fan at 25-35 percent. It’s used with deeper-pitch fans (2 1/2″ of pitch), and works well with higher operating rpm.

Severe-Duty Thermal Fan Clutch: Severe duty thermal fans turn the fan at 80-90 percent of the shaft speed when engaged and 20-30 percent when disengaged. It’s used with deeper pitch fans and has a larger working surface to provide cooler running and longer life expectancy.

Electronic – Viscous EV Fan Clutch Operation

This style of fan clutch operates like a thermal clutch, but the ECM/PCM signal controls the level of engagement of the EV clutch. This engagement process is ultimately controlled through the ECM/PCM by the following input variables: Coolant Temperature, Intake Manifold Temperature, Transmission Oil Temperature, A/C Pressure and Engine Oil Temperature. These variables are manufacturer-specific and fan speed is dictated based on the level of cooling required.

This style of fan clutch operates like a thermal clutch, but the ECM/PCM signal controls the level of engagement of the EV clutch. This engagement process is ultimately controlled through the ECM/PCM by the following input variables: Coolant Temperature, Intake Manifold Temperature, Transmission Oil Temperature, A/C Pressure and Engine Oil Temperature. These variables are manufacturer-specific and fan speed is dictated based on the level of cooling required.

Like all components, fan clutches will wear out and need replaced.

Signs of Worn Fan Clutch

According to Hayden, here are some signs your fan clutch might need replaced:

- Fan spins excessively when engine is stopped (three or more times when hot engine is shut off).

- Poor A/C performance at idle or low vehicle speeds.

- Fan speed does not increase when engine is hot.

- Fan speed does not increase until engine is excessively hot.

- Fan blade tip moves more than 1/4-inch front to back.

- Fan turns roughly or does not turn at all.

- Excessive fan noise at all speeds due to failed bearing.

- Vibration that increases with engine speed.

- Leaking fluid or oily build up around the bearing or thermal spring.

These problems are often caused by a bad bearing, which may be seized or have excessive play, or by a worn or loose thermal spring.

Armed with this information, you can identify a bad fan clutch and replace it with the proper aftermarket option.

Are you saying that, if you grab a fin and try to spin the fan but it stops very nearly as soon as you let go of it, the clutch is bad?

Thanks

Hey Ted, what I think you’re referring to is the first bullet point above, right? Here’s what it means: Get the car up to operating temps in your driveway, have someone in the driver’s seat stop the engine, and then watch the fan. It should stop spinning relatively quickly–but if, after the engine has stopped, it just spins and spins, then it points to a problem with your fan clutch.

You’re basically checking to see if the fan is “free-wheeling” and not engaged with the input shaft.

So I have a Nissan Frontier 2016 , we I start the truck the fans are normal then I turn the a/c on fans star working but then when I turnt the a/c the fans don’t stop so….?

You are talking about electric fans. Not at all relative to this site.

Is it ok to use a heavy duty fan clutch when a standard is normally used or came from the factory?

So my question is. I have changed out my fan clutch 3 times already and my car is still over heating? Changed it out again this past weekend stopped over heating but now less power? Then this morning started up had the power it should but once again started to over heat!! Please help me!! What is wrong with my car?? Its a 2002 Oldsmobile bravada.

Why on earth would you continue to replace it after the first replacement didn’t change anything? Since you have an electric fan clutch, did you check to see if it’s getting a signal from the ECM?

Do you think there could be another reason your engine is overheating? What is the age of the coolant? Has the radiator been flushed within the last 4 years? Was the thermostat replaced in the last 4 years? What is the age of the water pump? Did you prove the water pump is functioning the way it should? How about hoses? What are their ages? Did you ever see an old hose collapse? You have too many questions and not enough answers.

Do to need to have a belt driven pulley when running a spring actuated fan clutch and how does the water circulate around the motor without one

Yes, a spring actuated fan clutch would only be used on a vehicle with a belt driven pulley. On vehicles without a belt driven pulley, the water would be circulated either by a water pump driven by the timing belt, or by an electrical water pump. Either way, the cooling fan in such vehicles would be electrical.

With a thermal clutch fan if you remove the spring the fan will stay engaged !

I had to do that to a number of trucks to keep them running for the day R

I have a 95 Dodge ram van I replace the fan clutch because it felt like it was dragging wean it gat in normal temperature but now I replace it with a new one and now wean it get to normal temperature it’s dragging even worse than before second time I removed and replaced with a new one but no difference any idea?

I want to replace my fan clutch but when I go to the auto parts store they ask me for the ratios and say there is supposed to be a stamp on the old part but I don’t see it how do I know which one I need ?

180K on my 2004 Tundra DC V8. Replacing the fan clutch assembly since the radiator sprung a leak and it’s time for a T/B change so it’s ALL getting replaced. Aisin/OE Toy. parts ONLY. Truck still runs like new, but better since the cat back, ignition coils, dbl iridiums, K&N, and throttle body cleaning, and few other mild perf. upgrades. I live in Cali. so cant have too much fun!

Easy diagnosis. (1) When at a stop light (idling)and your temp gage starts creeping up quicker and higher than normal your clutch fan is failing. (2) With engine off and cold, spin your fan blade by hand. If you feel no resistance your clutch is failing. A working clutch will give you some stiff resistance when trying to spin it by hand when the engine is cold.

Your second comment is correct but the forest can be more than just a fan clutch. It could also be a falling thermostat, water pump, temp sensor, radiator, a partial blockage and even a clogged heater core. Just saying so people that read your comment don’t forget to check the entire system. Hate to just stop at a fan thinking that’s all that could cause the problem

2005 trailblazer, I have replaced the thermostat the water pump the radiator(3times)the cap and car is still overheating, 3 radiators have just about blown up like something I’d clogged!! I put water/coolant in the radiator drive for 10min sometimes less and car overheats I pull over and my overflow tank is as swollen as an elephant it’s like the water isn’t circulating and stays between the overflow and radiator!! Hense 3 radiators what’s wrong? I’ve replaced dam near all the parts but what would cause that? Is it clogged? And if so what is clogged… please help me I know very little about cars….oh and when you pour water in the radiator from there it travels where and then where from there and so on until it gets back to the radiator? Please tell me the point of travel from start to finish cause mine isn’t Making it all the way…. thank you very much… need help quick I’m stuck right now and stranded!! Please hurry…. thanx

Likely Blown head gasket or cracked head

Could a clutch fan a little smoke only in reverse. And I smell something but something but it only happens in reverse. The smoke comes out of the hood. It’s GMC 2500 series1 With A 350 .V8

How do you know if the clutch fan is not working,

Hi.

For the last 2-3 years we have had trouble with the a/c . It air is cold when it works. We travel around the country. But sometimes the cold air quits and blows hot air. We turn the a/c off. Wait 5-10 minutes turn on and it works fine. Have taken to different mechanics and all start with finding a leak. No leaks. 1.5. year ago Chey dealership installed a new fan clutch. Now it is getting worse and went to another mechanic in another state and they want to replace the fan clutch again. I have checked it and seem good. From what the website says to check. Do know what to do.

Thanks Benjamin

I forgot to add this on my last question. My truck is a 2001 Chevy Silverado 3500. Has 300,000 miles