If you’ve ever been in the market for a new fuel pump, there’s a good chance you’ve heard about “brushed” and “brushless motors.” But hearing about them and knowing about them are two separate things, so the guys at FUELAB put together an informative article on the topic.

As a leader in fuel system technology and products, FUELAB knows all about brushed and brushless technology. While the company is an innovator of brushless fuel pumps, the guys at FUELAB spend a fair amount of time talking about both styles of pump motors to inform their customers.

So what are the differences between brushed and brushless fuel pump motors? And why does FUELAB use the brushless design? We’ll let FUELAB’s Jon Light explain:

Why did FUELAB choose to use of brushless motors, rather than brushed motors? To answer this question, let’s first explore the design and operation of a brushed DC motor, and a brushless DC design.

Design and Operation of Brushed and Brushless DC Motors

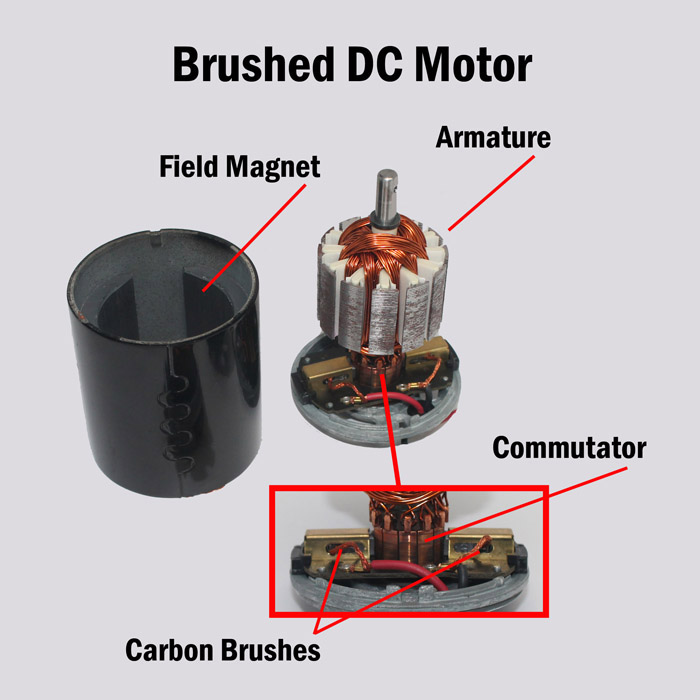

Brushed DC Motor

A DC brushed motor is comprised of four fundamental components: an armature (which holds wire motor windings, and magnets), a ring of magnets (or field magnet), carbon brushes, and a commutator. The ring of magnets and the brushes are non-moving, while the armature and commutator rotate together on the motor shaft within the field magnet.

The armature is an electromagnet, and the ring of magnets is a permanent magnet. The commutator is a split-ring component which is wrapped around the motor shaft and contacts the brushes, which are connected to opposite poles of the power source. The brushes charge the commutator/armature inversely in polarity to the ring of magnets, which causes the armature to rotate. Thereby turning the motor shaft and providing propulsion to that which the motor is driving.

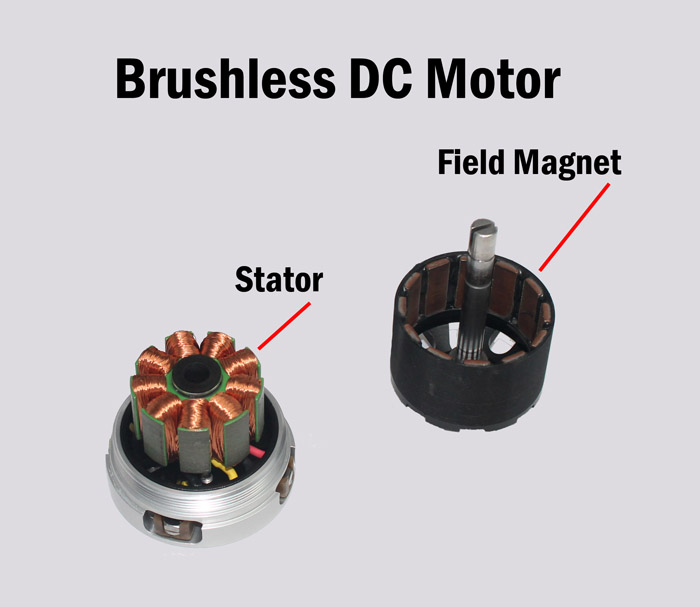

Brushless DC Motor

With a DC brushless motor, there is no armature. Rather, the wire motor windings (called a stator) are non-moving, and are “hardwired” to the power source. The field magnet rotates and is directly connected to the motor output shaft to provide propulsion.

The layout of a DC brushless motor can vary depending on whether it is in “outrunner” style or “inrunner” style.

- Outrunner – The field magnet is a drum rotor which rotates around the stator. This style is preferred for applications that require high torque, and where high rpm isn’t a requirement.

- Inrunner – The stator is a fixed drum in which the field magnet rotates. This motor is known for producing less torque than the outrunner style, but is capable of spinning at very high rpm.

DC brushless motors are more complex than DC brushed motors in the way the motor is charged. In the case of a brushed motor, the brushes simply charge the commutator/armature inversely in polarity to the ring of magnets, which causes the armature to rotate. With a brushless motor, a small circuit board coordinates the energy delivery to the windings which charges them inversely in polarity to the field magnet.

Above: Outrunner Style Brushless DC Motor

Now, let’s compare brushed and brushless DC motors.

Brushed vs. Brushless DC Motors

Magnets

Brushed DC motors typically use ceramic (ferrite) magnets, which are composed of strontium carbonate and iron oxide. The benefit of ceramic magnets is their high resistance to corrosion, and low cost. The downside is their moderate magnetic strength, and that they are brittle and break easily.

Brushless DC motors typically use neodymium magnets, which are composed of an alloy of neodymium (rare-earth metal), iron, and boron. Neodymium magnets produce significantly stronger magnetic fields than ferrite magnets and are the strongest and most affordable type of rare-earth magnet. Neodymium magnets have a higher magnetic density which allows more power from a smaller motor. The negatives are they are relatively more expensive than ceramic magnets, they rust easily, and extra steps must be taken to protect them from corrosion. They also are brittle and will crack under stress.

Conductive Efficiency

Brushed DC motors are not as efficient conducting electricity as brushless motors. Due to the interface of the carbon brushes (they are a less-efficient conductor than copper) and the copper commutator, a voltage drop is created.

Brushless DC motors are “hardwired’ to the power source. The copper-on-copper connection doesn’t cause a significant voltage drop.

Friction

Brushless DC motors don’t experience losses attributed to the friction of brushes dragging on a spinning commutator. Even though brushes are made from carbon for lubricity, friction still exists, thereby reducing the energy efficiency of brushed motors.

Motor Longevity and Reliability

Since brushless DC motors have no brushes to wear out, their service life is greatly extended compared to a brushed motor, which extends motor reliability over long periods. The brushes of some brushed motors are replaceable, which can also extend motor life. However, the chance for motor failure due to brush wear is eliminated with a brushless motor.

Size/Weight

As previously mentioned, neodymium magnets have a high magnetic density which allows more power from a smaller motor. Therefore, the brushless DC motor used for a particular output need can be smaller and lighter than its brushed counterpart.

Submergibility

While in operation, brushed DC motors shouldn’t be submerged in some fuels, as it can cause premature brush wear and failure. This is especially true in diesel applications: fuel with ultra-low sulpher content has low lubricity. Brushless diesel fuel pumps are designed typically with a shaft seal to ensure fuel doesn’t submerge the motor. These seals often wear and fail, allowing fuel to leak into the motor bearings, which is one of the main reasons for brushed diesel pump failure. Brushless DC motors can be submerged in fuel during operation without issue. So, brushless pumps have no need for a shaft seal, which promotes reliability and longevity.

Submersion capability also allows for liquid cooling of the motor — which is especially beneficial for a small, high-energy motor that can generate much heat.

For gasoline applications, a benefit of submergibility is that the gasoline helps keep internal components from corroding. In a brushed system, the non-submerged motor is subject to corrosion.

FUELAB uses brushless DC motors in their fuel pumps as the overall efficiency, long life, and reliability, the technology offers is superior to that of brushed motors. Furthermore, since more power can be obtained from a lighter motor, our fuel pumps are lighter, and they can provide more flow than similarly sized brushed-motor fuel pumps.

Commutator and rotator for soler pump

If have so please call in wechat

My wechat no 0705356521

We produce more than 200+ models brushless dc pumps for various application, such as PC, automobile, water heater, bathroom equipment, aquarium, household appliances, and other fields. Know more about our products please visit https://www.vovyopump.com

Where to buy “quality” commutator, bearing and carbon brushes ?