How much horsepower does it make? How much torque does it put out?

These are usually the first questions enthusiasts ask when it comes to buying parts for his/her street machine or race car. The reality is, however, that many of the parts we need for these cars don’t offer any improvement in horsepower or torque. Oftentimes they are required for safety or other reasons, but not improving performance. Such is the case with oil pans and stroker engines. While certain oil pans can offer improved performance via windage trays and crank scrapers, more often than not, they are needed to make room for internal engine components or additional oil supply.

We found this out first-hand on our 383 stroker small block Chevy engine build after we noticed the connecting rod bolts were contacting the factory oil pan. Its rotating assembly was fitted into the engine block and the proper clearance was made to said block; however, the oil pan didn’t seem to create any issues upon initial assembly and thus it remained part of the build.

Startup revealed a slight knocking noise that quickly went away, and subsequent engine break-in and dyno testing showed no ill effects. Realizing there was a slight leak at the back of the engine while on the dyno, it was determined that resealing of the rear cover as well as the oil pan gasket was the next order of business before the engine found itself between the car’s fenders.

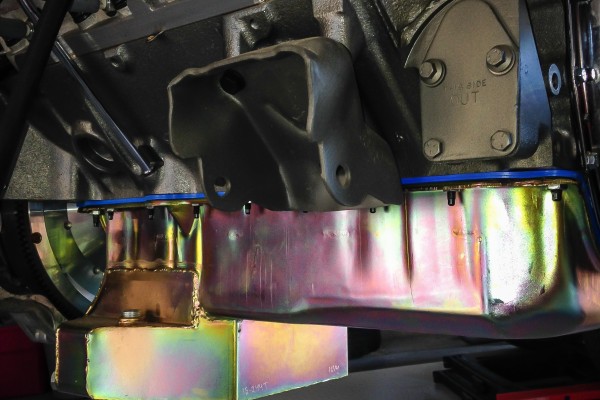

Upon removing the stock oil pan, the two shiny scrape marks in the bottom of the pan at the front were immediately apparent against the black pan. Further inspection revealed that the rod bolts were striking the pan in no less than five different spots — two at the bottom and the remaining three on the sides near the pan rails. Realizing we needed an aftermarket solution with the proper clearance for a stroker combination, we looked for the available pans for our subject vehicle, a 1987 Firebird Formula. We went to SummitRacing.com and found a suitable pan from Canton Racing Products (CTR-15-244T), as well as the associated parts to go with it; those being the oil sender port plug (CTR-22-405) and the oil pump pickup (CTR-20-010).

This particular oil pan offers a five-quart capacity (six including the oil filter) and clearance for a 3.875-inch stroke length with an OE-length connecting rod. It is designed for use with 1986-newer blocks with a one-piece rear main seal.

While the stroke clearance available in the pan’s design is usually specified either on Summit Racing’s website or in the Canton catalog, it never hurts to discuss your particular combination with a technical representative. To get a better idea of the clearance issues enthusiasts might face, we contacted Canton Racing Products and spoke with Bob Vaughn in the company’s technical support department.

“Clearance has become more of a problem in recent years as everyone is building stroker engines,” Vaughn siad. “You don’t just bolt stuff together; you have to do your research and check things like clearances.”

As Vaughn pointed out to us, most stroker combinations present a problem when it comes to oil pan clearance.

“One of the most important things that we always ask is what is the stroke of the motor,” Vaughn said. “We have a fitment chart and the choosing the right pan often depends on whether the customer’s engine has aluminum or steel rods, and I-beam or H-beam designs.”

As you might expect from an oil pan company, the opinion there is that an oil pan is just as important as any other high performance part in your motor, and they’re not wrong. The oil pan does more than just hold the oil, especially aftermarket oil pans.

“Aftermarket pans usually have more capacity, so oil becomes a bigger heat sink,” noted Vaughn. “More oil means it doesn’t go through the engine as many times, so it lasts longer and stays cooler.” This can be especially helpful for those running expensive racing oil.

Even with purchasing an oil pan that states a certain amount of clearance, it’s important to install it and turn the engine over by hand to verify nothing is catching, especially pans with crank scrapers and windage trays.

“Put the pan on and rotate it in reverse and make sure it clears properly. If you feel the crank scraper snag, you can bend the scraper a bit to clear,” Vaughn said. “If you rotate it in reverse, it will catch the scraper, where as in normal rotation, the rod can push past the scraper and you may not notice the change in tension.”

And with any aftermarket pan, you’ll also want to make sure you have the correct oil pump pickup —most aftermarket pans are deeper and/or wider and the stock pickup might not be optimally positioned and work properly.

Another aspect of aftermarket pans that people don’t often consider is how to ensure you have the proper oil level. How the oil capacity is measured varies from manufacturer to manufacturer, and it sometimes includes the amount of oil in the pan and the filter.

“A lot of dipsticks are not calibrated to the pan,” Vaughn said. “Your stock dipstick was calibrated to the stock pan. Put whatever the aftermarket pan calls for in; if the pan calls for the original stick, your new full mark is where the oil level comes to rest on the stick. Read the instructions!”

One last thing you may want to discuss with your oil pan manufacturer is gasket type. Certain pans and their manufacturers prefer certain gaskets based on design and/or success with their sealing properties, so be sure to consult them about that before you hang up.

My mechanic outsourced the rebuild of my 350 into a 383 and then ran it with the stock oil pan for a few minutes before realizing there was something hitting the oil pan and shutting off engine.

What’s the chances something got wrecked with the engines internal components?

Thanks

[…] Download Image More @ http://www.onallcylinders.com […]