What is a general safe effective compression ratio on E85? The internet results in varying opinions from 13:1 up to an extreme 20:1.

Jeff Smith: This is an interesting question that came out of last month’s discussion about E85. To quickly refresh, E85 is 85 percent ethanol (grain alcohol) and 15 percent gasoline. It has a commonly accepted octane rating of 105 although that may vary depending upon the quality of the 15 percent gasoline. According to Tim Wusz of Rockett Racing Brand fuels, the quality of that blended gas may not necessarily be as good as 87 octane. So with that as a variable, we might safely assume the octane to be closer to around 100. Rockett sells its own brand of race E85 listed as 112 octane. All gasolines use an anti-knock index (AKI) for the octane number created by averaging the fuel’s detonation-suppressing capabilities based on two very different tests. The first is a calculated number called Research octane and the second is Motor octane generated by actually testing the fuel in a variable compression ratio single cylinder engine.

In the case of Rockett Brand’s E85, the Research number is 116 and the Motor number is 108. Adding the two and dividing by two ((R+M) / 2) produces an AKI of 112. Evaluating these numbers, the “real-world” Motor number is always lower, but the goal is to have the two numbers be relatively close. Wusz says that of the two numbers, greater emphasis should always be placed on the Motor octane number.

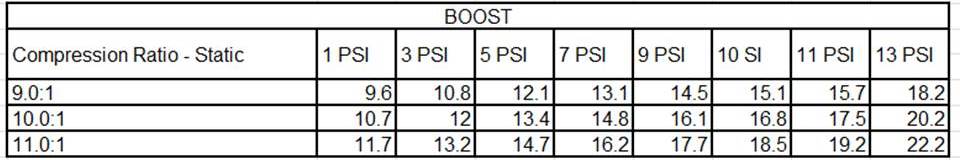

Before I get too deep into this, let’s try to quickly answer your question with some actual dyno testing as opposed to just theory. As I mentioned last month, we tested a small block Chevy with a static 10:1 compression ratio with 9 psi of boost using E85. This was run on normal E85 and we checked to make sure the fuel was actually 85 percent ethanol and according to our test it was very close. The engine ran perfectly and we experienced no detonation problems. If you look at our Effective Compression Ratio Chart (we’ll explain what that is in a moment) this would be like running a normally aspirated small-block with a 15:1 static compression ratio. The engine made 600 flywheel horsepower using a Magnuson supercharger.

One way to estimate the actual static compression ratio is by using a simple formula that produces a result referred to as Effective Compression Ratio (ECR). This simple formula converts the amount of boost to additional compression ratio as if the engine were normally aspirated. This formula does not take into account the increase in inlet air temperature that occurs when you compress air – we’ll get to that later. Given that warning, the formula looks like this:

Effective Compression Ratio (ECR) = [(Boost / 14.7) +1] x Static Compression Ratio

Let’s plug in our 10:1 compression engine with a psi of boost into this equation:

ECR = [(8 psi / 14.7) +1] x 10

ECR = 15.4:1

This reveals our engine was running an effective compression ratio of over 15:1. That means that you could reasonably build a 14:1 compression ratio engine and run it on E85 and not expect problems with detonation. This also reinforces Rockett’s listing their E85 fuel as compatible with a normally-aspirated engine with up to 16:1 compression ratio.

To answer your question directly, it appears both from our ECR chart and our own testing that you could run E85 on a normally aspirated, static compression ratio of 15:1. The issue becomes the ability to generate that much compression. My guess is that a huge domed piston would hurt combustion efficiency more than it would help. We did a quick scan of the JE piston catalog and the highest compression off-the-shelf piston for a big-block Chevy, for example, was 14:1 with a 112cc chamber.

According to Wusz, even given the cooling effect of E85, his recommendation would be to limit the static compression ratio to 13:1 on a 4.00-inch bore small block and slightly lower in a larger bore engine like a big block Chevy. His recommendations will be conservative since we were talking about pump E85 as opposed to his company’s version of E85 which has a significantly higher octane rating than normal pump E85. There’s still plenty of advantages to building a street engine with high compression that will take maximum advantage of the fuel’s reduced energy content.

Remember that cylinder pressure is directly affected by cam timing. This is because compression cannot begin until the intake valve closes. This means that a late closing intake point (with a long duration cam) reduces the engine’s dynamic compression ratio. If you put a mild cam in a 13:1 compression engine, the dynamic cylinder pressure might be equivalent to 15:1 with a larger cam. This is certainly a bit of a no-man’s land since there probably aren’t too many people with practical experience along these lines, so you should perhaps be conservative and keep the compression in a range where everything is manageable. Then there are other considerations such as how difficult it will be for the starter motor to crank over a hot, 15:1 compression engine.

The big advantage that E85 has over gasoline is alcohol’s excellent latent heat of vaporization. This is a fancy term for alcohol’s ability to absorb heat when it evaporates. If you’ve ever swabbed your skin with rubbing alcohol, it evaporates quickly, leaving your skin feeling very cool. The alcohol in E85 does exactly the same thing in the intake manifold, cooling the air as it evaporates. This reduces the inlet air temperature. This is important because cooler air is more dense, which means it packs more oxygen into the cylinder for the same volume of air.

Next, because of the cooling effect, we can safely assume that the inlet air temperature for our normally-aspirated engine will be dramatically cooler using E85 fuel. This number is a little harder to predict, but I think it would be safe to estimate the inlet air temperature entering the cylinders could conservatively be 25 to 30 degrees cooler than ambient air temperature. This is important because Wusz says that based on OE testing, for every 25-degree reduction of inlet air temperature, the engine’s octane requirement will be reduced by one full octane point. So if our 14:1 engine really was at the knock limit of the fuel with an inlet air temperature of 80 degrees, reducing this by 30 degrees would mean the engine is now “safe” by roughly one full point of octane – which is a significant drop. Cooler air is denser, which should produce higher cylinder pressures and nudge the engine towards detonation. But as we’ve mentioned, cooler air also reduces the tendency for an engine to detonate. So colder air is always better and E85 is very good at cooling the air entering the cylinders.

We’ve included a couple of charts that may help make all this a bit easier to understand. As you can see, there are a ton of variables, but the bottom line is that I think a 13.0:1 big block to perhaps 13.5:1 small block engine would be very responsive when running on E85 and that extra compression will return some of the lost mileage from E85’s reduced BTU heat output compared to gasoline. Think about that – a 13:1 compression street motor on E85 that makes excellent power that could also deliver acceptable mileage. Very few people believe that’s possible – but I think it is.

Anti-Knock Index Chart

The AKI number is calculated by adding the Research and Motor numbers and dividing by 2.

AKI = (R + M) / 2

Effective Compression Ratio (ECR) Chart

This chart is a just a guideline, but if we assume we can safely run an ECR of 16:1, then a static 10:1 compression with 9 psi of boost is an ECR of 16.1:1 and that’s exactly the combination we safely ran on the dyno.

even with an agressive ramp cam and minimal overlap .14.4 on a 4.04 bore is still good . running through max torque lean to rich on the pass there was no sign of detonation . timing and valve lash were no crutched to do this either. with the plugs showing on the bend andva light furl ring .1.5 theads of heat.

We have ran 30psi on E85 at 9.2:1…went 5.17@141@3250# on 8.5″ even.

I have a 540″ BBC, with a pair of 80mm Turbos. In a 68 Camaro. We make 24lb of Boost. Car is 3700lbs yes 3700. We figure it makes about 1750 up to the tires been 7.60 at 185. Plugs what heat rang do you suggest. Ran #9. NGK when it was on 20lb but went to 24 and got a piston . total timing when at full Boost is 24 degrees. What do you think ?

Way too much timing:/ 14 to 18 degrees at redline. 22 is max if conditions are perfect and cool ambient temps with good intercooler.

I do believe your statement of E85 being 105 octane is not a factual statement.

The E85 personnel from National Ethanol Vehicle Coalition (who later became Growth Energy) and I sat at lunch one day discussing E85 and the properties and make up of E85.

The direct quote from the NEVC was that the federal government mandated that “Any and all Ethanol blends sold at the pumps must list a minimal fuel blend, this minimal amount is listed on the pumps as E70, and is stated so by a decal” They then went on to state that “the Federal Government also required an octane rating to be listed and since there was no way to know exactly what blend was in the ground tanks they were forced to use the minimal blend listed on the pump” Alcohol cannot technically have an octane rating due to the latent heat vaporation that happens so they had to base an octane rating off of the E70 blend, Which IS 105. …

Back to Back Dyno testing has shown that E70 makes power near that of 105 octane race fuel, we also discovered that E85s power is near that of 114-116 octane race fuel, and the over all best blend we have found to work is E87, this has enough Gasoline in it to start the burn process but yet retains enough Ethanol to keep the cooling effects of the Alcohol.

Very well written article, Very informative….Thank you for the positive press on Ethanol based fuels.

This was my question! Awesome to get a full article response.

^ Also cool to see Mark Sullens post above (E85 Carb Builder). I’ve spoke to him on the subject as well.

next chapter is e85 23* sbc @10.5-1 on spray. should push 4 digits for low eights

sorry mark sullens its efi now .

the rest of our group is still all top 5 is class with your carbs and help.thanks

Baker Motorsports

Is there a way to do an article about blow thru carbs on e85?

Lmk thank you

Have a small block mopar 416 running on the street that has 195psi on a compression gauge. Love this stuff. I made 527hp on the dyno and 560 torque at the flexplate. This all with cast iron heads.

i have a naturally asp, mopar 360 with 10:5:1 compression. Im tired of listening to buddies that don’t know. But what and if any boost can I run on this motor? I have no idea what cam or any internal specs other than comp. ratio.

assuming your rings are gapped for a turbo application. i would follow the chart above. e85 and turbo will be a tremoundus power increase. your definitely gonna have to go bigger with your fuel system to support. you definitely want a cam that has less overlap. too much over lap and you are gonna have blow back issues which will kill your airflow. cam selection is super import when it comes to boosting engines. dm me if you have any questions my instagram is hemitech57

Jeff I have a question I am building a 427 cubic inch Dart motor LS3 head with a Kenne Bell 4.2 I am looking for maximum horsepower out of this motor What compression would you recommend the blower is capable of 32 pounds of boost it will be E85

I think 10.0 would be great at 25psi, but, to be on the safe side I would shoot for 9.5 at 30psi or above. That’s just my opinion. I run a ford, so I can’t be very smart. It is 12.7 Windsor with 3.75 stroke and 6.25 rod. The long rod, I think helps. It works good on e85.Timing is locked at 30°, down from 34° on 110 Oct race gas.

“Think about that – a 13:1 compression street motor on E85 that makes excellent power that could also deliver acceptable mileage. Very few people believe that’s possible – but I think it is.”

Well I did just that. Built a 13:1 compression street motor to run e85. But I’m currently getting 3.5 MPG. Any suggestions?

I imagined the 2.73:1 highway gear would help with fuel economy but with the load of a 5500 lb car and a highway gear on the engine, I think I’m encountering detonation.

I also had the “mild” cam installed 2 degrees advanced with the build and have since set the cam to 4 degrees retard in attempt to reduce low end cylinder pressure.

I’m pulling out ignition timing and still can’t open throttle past 1/4 without experiencing engine shuttering upwards of 1700 RPM. I believe the power should feel smooth?

I’m working with a 426 max wedge with a 4.5″ stroke. FiTech Fuel injection controlling MSD ignition. I’ve tried everything including octane boost to avoid lowering compression but I think I’m going to have to add about 10cc to the combustion chamber in order to run e85 in a 5500 lb car with a highway gear and 600 fl lb of torque at 3000 rpm.

Any other suggestions?

Is it reasonable to conclude that a heavy car with a highway gear can make a big difference in the amount of compression you can afford on e85? Because that’s what I’m believing based on this experience. I think 12:1 should be safe. I’m planning on going down to 11.75:1 because that’s what 83cc heads will give me and it should effectively get me into the safe zone so I can use the throttle.

I hypothesize if this motor “as is” was in a dart with a 4.11:1 rear end gear there would be no issues with detonation. Is it reasonable to think that or should I be looking elsewhere?

With 13:1 compression I would need to know your exact cam specs but it seems unlikely that your engine should be experiencing detonation. Granted, the vehicle is very heavy. It would be also good to know your ignition curve at the rpm that you say the engine is detonating. You mention a shudder – that could be something else related to the tune rather than detonation. If the engine is rattling as you say – do the spark plugs indicate detonation? That will appear as black spots on the insulator of the spark plug. It’s also possible that this tall a gear with a tall tire could be lugging the engine -combined with too much timing could make the engine struggle. I would look into the tune before making a major change. But reducing the compression will only hurt the efficiency and fuel mileage. That is a given with any fuel.

Currently building a .100 over 454, and have 15-1 Forged domed pistons. Excited to run E85 and run as a street car, and for the consistency in bracket racing. I planed to bring the come down to @ 13.5:1, but reading articles like this confuse me. Engine Masters rated the rocket brand e85 at equal to 114-116 octane, and capable of keeping a 13-1 468 BBC out of detonation, and clearly the rocket brand is much better than at the pump e85. But here saying pump e85 can run on 14-1. WTH? I am putting my engine together this week! With these pistons, I plan to mill off the sections that form above the top of the valve reliefs. I have 122 cc chambers on 049 heads. Also, my cam is a Comp Bug Mutha Thumper, which has 90 degrees of overlap, @ .522/.505 lift; 246/255 duration @.050; on a 107lsa. Even if this cam “bleeds” off some compression at low rpm, it will not bleed off as much at 6500 rpm. But, if I can run 14-1 compression, that is 3 to 5 percent more power! But here folks are saying it isnt as efficient. I just witnessed dragsters running 16-1 with 2psi boost, or 13-1 with 10psi boost! Confused, and hoping to make videos of my build as testimony on what works and what doesn’t.

you don’t, won’t learn anything without trying different things and having a go.this is what separates those who can, & those who can’t.

Thanks for all the info. I’m decided that even if I am leaning into the 14-1 compression area, I will assume safety, but still watch closely. Non boosted, but sprayed from time to time, 150 to 275 shot.

Been weighing on me heavily, should I sacrifice quench distamce by using a thicker .060 gasket? Or stick to what I know, using right quench.

My mock up comes .010 from flush. Like to keep total around .030 to not more than .041.

I think I understand from the article that the e70 is @ 105 octane, e85 more @ = 112 (varying).

The only local e85 pump here is tested regularly and is dead on 85 to 90 percent ethanol. And I think that is the case in most e85 because ethanol is cheaper, and the seller stands to make a better profit from higher ethanol content selling for same price.

Eager to fire this 476 up in my 69 Corvette.

A tighter quench clearance of around 0.040-inch with steel rods is always a good idea as long as it does not increase the compression beyond your goal. So if you can run something like a 0.040 piston-to-head clearance (quench) and put the compression at 13:1 that should work very well. Be sure to carefully measure piston dome to head clearance and that includes the spark plug. Checking this first before finalizing the combination is a great way to prevent problems later on.

https://www.youtube.com/watch?v=HloO93N5DjE

I run 30. But thats me.

Ok, thanks Mr. Sullens, and for this article. Took me a few times re-reading to completely digest all the info. I do think I’m on the right track, and this article and these replys help confirm. I’m shooting for 14-1, in a 3000 lb. 69 Corvette.

I believe in the above reply (Mr. Nathan Wyse), at 5500 pounds, with highway gear, before I changed heads to lower Compression, I would try a slightly larger cam with more overlap, before resorting to head change. Not sure on their current cam specs, but assuming mild from gearing choice (2.73?). When I say larger, I’m meaning generally more duration.

Also of interest, generally, an engine will most likely experience pre-detonation (ping) at the rpm which it creates the most torque. If you have a MSD Grid, or can influence timing ramp to not ramp up until past 3200, may help. Try unplugging vacuum advance, and lock the ignition out at not more than 30 degrees total, if not slightly lower. As Jeff Smith wrote, the timing curve will influence tenancy to experience pre-detonation, as same with gasoline.

I wish I could show pics, but maybe I can make an informative video for record, or informative testing if noting else.

I have a 489 Big Block with 12.7 compression would like to try E-85 what do i wave to do to my carburetor,the fuel I’m running now is sunoco supreme 112 leaded

It will probably require a dedicated E85 carburetor – look at the carbs from Quick Fuel carburetors – they have dedicated E85 carbs in a few sizes.

We tried just converting the metering blocks but found the discharge hole in the main body to the boosters was the real restriction. A annular discharge booster carb would be best – they are more responsive and flow more fuel.

Talk to Eric N. at Horsepower Innovations I have been super happy with the carbs he built for me. Spot on.

I have a 489 BBC with close to 14.1 CR, has a .715 lift 280 intake, 294 exaust @ .050 how would this set up do on the street with e85

I have a 383 sbc that is around 14:1. The cam is a solid roller with around 240 degrees duration at .050. it has 275 lbs of cranking compression and I run e85 with no problems. I am running 32 degrees mechanical advance and 45 total with vacuum advance. The engine also runs very cool usually 170-180 with a 195 thermostat. It rarely gets hot enough to build pressure. I am running flat top pistons zero deck, with very small chamber heads(53cc including head gasket. It also gets similar mileage to what it did running gas with 11:1 compression.

HI.. I HAVE A 350 WITH FLAT TOPS AND I WOULD LIKE TO USE MY 64CC 186 CAST IRON HEADS PROBABLY BE AROUND 10 TO 1 COMP.BEING SMALLER VALVES. COULD IT GET BY WITH 95 OCTANE…OR WOULD IT GET TO HOT.. THANX ….THE POOR HOT RODDER..

I’ve switched my racecar to E85. I have a wide band O2 gauge that reads E85 numbers. What I need to know is what’s the safe number on E85 gauge at wide open throttle. The engine is a Bug Block Buick with 12.4 compression. The bore is 4.350.It is a carburetored NA engine.

Thanks for help.

I purchased an L88 427 BB chevy over the counter crate motor in 1971 which was never used. I want to put this in my 1972 Nova, but there is an octane warning that says DO NOT use anything under 103 octane. It has like 12 or 12/12 compression ratio. Can I use High E85 fuel to drive in it safely.