Ford’s timeless FE series big-block has been making legendary amounts of power for nearly 60 years with those first examples showing up for ’58 in Ford, Mercury, and Edsel. Early on, displacement wasn’t much to write home about with its 332-, 352– and 361-cubic-inch options. However, Ford engineers and product planners quickly went to work infusing more displacement into this history-making big-block series, ramping up displacement to 390, 406, 410, 427, and 428 cubic inches. There was also the 360 FE for trucks.

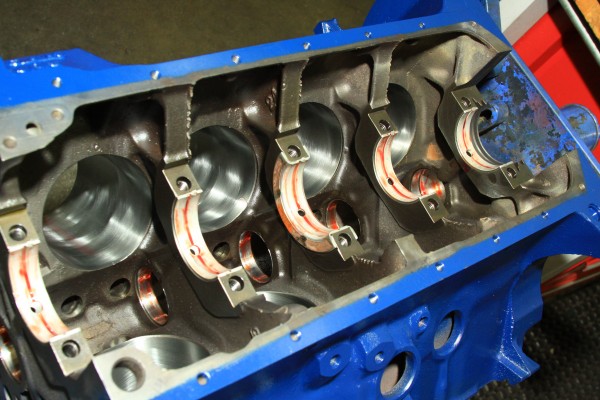

Of all the FE series big-blocks produced during the type’s 18-year production run, the 390 is easily the most common. With a 4.050-inch bore and 3.780-inch stroke there’s plenty of room to grow this engine into a 430-plus cubic inch beast without spending a lot of money. And once you have the increased stroke from Eagle Specialties and resulting displacement from a cast steel crank and I-beam rods, Summit can help get you into real power with Edelbrock Performer series cylinder heads and induction, a COMP Cams roller hydraulic camshaft and Crane Cams roller rockers, Pertronix or MSD ignition, Holley carburetion, and more. You can scarf it all up in one stop and wait for UPS to knock on your door with the goods.

We stopped by JGM Performance Engineering in Valencia, CA, which was building a 390 FE stroker for a Pennsylvania customer with a Mustang. We were astonished by the power JGM was able to get from a modest increase in stroke using cast iron 390 GT heads and 428 Police Interceptor induction topped by a Holley HP. JGM was able to get 450-plus horsepower and roughly 400 ft.-lbs. of torque using Ford heads and induction, a hot Crane roller hydraulic cam, and a very detailed approach to tuning on the dyno.

I am trying to install a 428 fe stroked to a 462 into my 73 mustang. Any advice on engine mounts to help me or do I have to fab my own?

Made a quick call to our friends at Summit, and they currently do not make or offer a mount for this combination!

Hi there I have a 390fe block bored .060 and I am considering a stroker kit. Would there be a stroker kit available to suit .060 piston size. What heads and cam would work on a street car

Thanks

I have a 390fe bored .030 an I want to stroke this engine.. I’d like to buy a complete striker kit

The FE/FT blocks were poured from 1957 to 1979 (that’s 22 years). My 1979 F-350 came from Ford with an FE/FT 330 2V.

Eagle advertises “cast steel” crankshafts – but they are not. They may be nodular iron, but that doesn’t mean they are steel.

I have a 390ford an concedering a stroking it

Are you sure that the power numbers are correct? A 431 should be 500 ft lbs and 425-450 hp. The 390 stock made 430 lbs ft and 355 hp. With a 4.125 stroke that doesn’t sound tight. My .020 over 390 is making 465 lbs ft and 488 hp with home ported iron heads.

which headers fit best with a 390FE engine i am stroking the 390 to 445 Cubic inch 390FE and putting in a 1989 mustang coupe fox body mustang

Hey Michael, cool build! We’re big fans of Foxes around here, and so are the Summit Racing folks. In fact, click here to contact the Summit Racing tech department. They’ll ask you a few specifics on the rest of your Foxbody build and give you some solid header recommendations.