Flat plane crankshafts are nothing new.

However, with the recent introductions of the Shelby GT350 and GT350R, flat plane crankshaft design has been garnering a lot more attention. And it’s been raising a few questions, too. Namely, what is a flat plane crankshaft? How does it differ from a crossplane crankshaft? And what are the benefits to a flat plane crankshaft?

In this post, we’ll look at flat plane crankshafts vs. crossplane crankshafts. We’ll start with the crossplane crank, since you may be a little more familiar with that design.

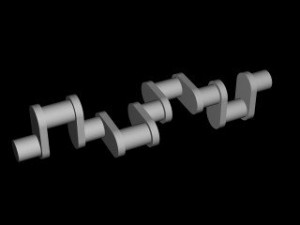

Crossplane Crankshafts

Crossplane Crankshafts

The crossplane crankshaft is used in most every production V8 sold in America today.

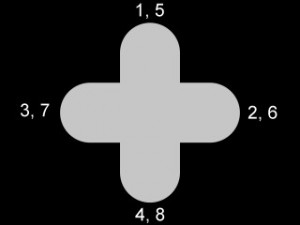

On a crossplane crank, the four crank journals are arranged at 90-degree intervals (see image at left). When you look at this type of crankshaft along its axis from either end, it resembles a +. Hence, the name crossplane.

Using the traditional V8 firing order of GM, AMC, Mopar, and most Ford OHV V8s (1-8-4-3-6-5-7-2), a cross plane crankshaft will produce unevenly spaced firings within each side (or cylinder bank) but ensures there’s a balance between the two banks. This is what gives American muscle cars that distinctive burbling sound, although there is some sacrifice in the amount of exhaust scavenging that takes place.

The basic configuration of a crossplane crankshaft when looking from the front. (image courtesy of e31.net)

Another distinctive characteristic of the crossplane crankshaft is its counterweights. These counterweights are required to keep the engine properly balanced and prevent it from rocking up and down. This reduces vibration (a problem with many flat plane crankshafts) and fosters smoother operation; however, it also adds rotational mass, which makes this crankshaft less desirable for really high-revving engines.

That brings us to the flat plane crankshaft.

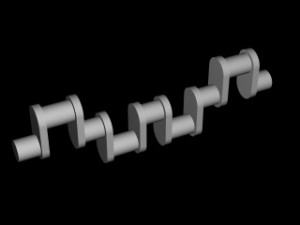

Flat Plane Crankshafts

Flat Plane Crankshafts

The flat plane crankshaft used in the new 5.2L engine is the first ever in a production Ford engine, but flat plane cranks have been around forever.

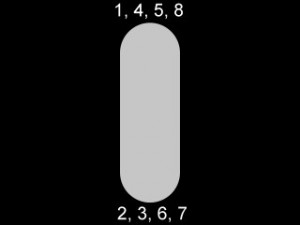

Flat plane crankshafts have two pairs of journals 180 degrees apart from each other. When viewed from either end, these crankshafts look flat (see illustration below right). No matter the firing order, flat plane engines will always alternate back and forth between the two cylinder banks. This produces more efficient exhaust scavenging without the need to have header primaries cross over from one bank to the other. It also gives the new Shelby GT350 a totally different sound from other American performance cars–as this video shows:

Another thing that differentiates a flat plane crankshaft from a crossplane crank is the lack of massive counterweights. Without the additional mass of the counterweights, the lighter flat plane cranks will spin more easily than their crossplane counterparts, making them more ideal for high-revving, high-rpm applications. The downside is flat-plane crankshafts tend to create more vibration within the engine without the help of counterweights.

Flat plane crankshafts are typically found on race cars and high-end exotic cars because of their high-rpm performance. In most cases, race car drivers don’t mind a little extra vibration in their engine, and exotic car companies will spend money on lighter-weight materials to reduce vibration in street-oriented cars. Since the flat plane 5.2L V8 will be used in the high-end GT350/GT350R, we’d expect many of those vibration problems to have been addressed by Ford as well.

Most flat plane crankshafts have a shorter stroke than crossplane designs. That means less crankcase space is required; however, shorter strokes often lead to lower torque output.

The Bottom Line

Crossplane Crankshaft Advantages: Smooth, vibration-free performance; distinctive American muscle car burble.

Crossplane Crankshaft Disadvantages: Heavier (harder to rev), requires larger crankcase.

Flat Plane Crankshaft Advantages: Lighter, more compact, more responsive (high-revving), better exhaust scavenging.

Flat Plane Crankshaft Disadvantages: Prone to vibration, lower torque levels.

Thanks, will make good bench racing

If I remember right, flat or as we knew them 180 degree cranks were used at bonnivel in ford flatheads.

!956 I hitched a ride in a 32 ford with a 180 degree crank The old man driving explained the vibration was from the crank. He raced at Bonneville.

Our local circle track had a flathead ford 180 degree crank.

yes

Ford has come a long way,It,s nice to see mustangs are going to sound more like a jag. or a Jetta,all they need now is the big headlights on the roof

A Mustang should not sound like that.

Ah, forget that, I just assumed it would sound like a Ferrari. Then I watched the video and… how the heck did they make a flat crank sound like that?

nothing sounds like a ferrari.

because 12 cyls don’t sound like a V-8

yes, especially at full chat on the mountain parkway.

Still sounds like a Coyote to me.

Flat plain cranks fire a cylinder every 180 degrees, it takes 4 revolutions to fire all 8 cylinders, 180 degrees is a huge gap, cross plain cranks fire every 90 degrees. Hense 90 degree V8. It takes 2 full revolutions to fire off all 8, that’s why cross plains are so smooth, there is only 90 degrees of crank rotation before another cylinder fires off.

Somewhat correct, in every V8 engine, 2 combustions happen after 180 degree rotations. A crossplane fires 1 every 90 degrees, so 2 after 180 degrees. In a flat plane engine, 2 combustions happen at the same time every 180 degrees of rotation, that’s why it is so lous. And as the revs go up, the combustion gaps are offset by the RPM and more power can be produced. Since there is more mass in a crossplane, there is more momentum and that also helps its higger torque output.

you guys are both wrong. Using the 90 bank angle in the V8 you still have a 90 firing interval with the flat crank.

OMG, I hope you actually don’t work on engines.

My previous comment was meant for Max.

A four stroke engine cylinder fires every two revolutions. An engine cylinder that fires only every four revolutions would be an 8 stroke motor which hasn’t been invented yet.

OMG! STEVE I HOPE YOU DON’T WORK ON ENGINES!

4 stroke engines fire all of their cylinders every 2 revolutions of the crankshaft. So 720 degrees divided by number of cylinders is how many degrees the crankshaft rotates to fire each cylinder one at a time. V8: 720/8=90deg V12: 720/12=60deg I6: 720/6=120deg…and so on. The degrees between banks of cylinders is totally based on what the designer of the engine needs/wants.

Flat crank V8’s fire every 180 degrees . It just fires two cylinders. It’s like an inline 4 and a v twin had a baby. It would be impossible for a flat plane crank to fire every 90 degrees. It’s science

Mr right: You forgot the 90° V angle, that’s what makes flat plane V8 an even firing interval. In fact both crossplane V8 and flat plane V8 have even firing interval of 90°. The difference is whether the firing interval is even for each bank of 4 cylinders. In flat plane V8 yes just like an inline 4 but in crossplane V8 no. And in terms of firing two cylinders at once. It’s a special V8 design called Big Bang, not a conventional V8 design.

Ford could solve this issue with a Boxer engine and design the Mustang around it. Maybe have it look like the snowmachine that was made into a three wheeler road car.? Paint it Oxford White, put two blue stripes down the middle and solve the problem.

Thanks, nice explanation.

That would make them an 8-cyle engine, not a 4-cycle. Flat plane’s also fire all 8 cylinders in the same 2 revolutions as a cross plane. Cyl 1 & 4 come to TDC at the same time but on opposite strokes (intake vs exhaust) mirrored by cyls 5 & 8, And they’re offset by 2&3 and 6&7, respectively, on the second rotation. Think of it like firing 2 cyls at a time, every 180 degrees of rotation, on opposite banks. (Assuming left bank numbered 1-4 and right bank 5-8)

Jeez all the answers above are embarrasing.

If a crankshaft is flat, then each bank of 4 cylinder will see the outer cylinders together at tdc, with the inner cylinder reaching tdc 180 degrees later. Although on each bank 2 cylinder reach tdc together, one will be on compression stroke, the other exhaust.Each bank will fire it’s cylinders at 180 degree intervals. The other bank is doing exactly the same, but phased 90 degrees later, so the engine fires one cylinder, on opposite banks, every 90 degrees. Anyone questioning that must answer how V8 ignition distributors worked with flatplane cranks before modern coilpacks came along!

With a 90゚ V-engine with a flat plane crank the cylinders fire every 90゚. When a cylinder of one bank is at top dead center another piston on the other bank is 90゚ before top dead center. So it will fire 90゚ later.

Correct me if I’m wrong.

This is not correct. Both flat plane and cross plane V8s fire every 90 degrees provided there is 90 degrees separation between the bank. Both cranks will result in two pistons being at TDC at the same time – one on compression and one on exhaust. On a flat plane, the two that are TDC at the same time will be on the same bank. 90 degrees later two will be TDC on the other bank. One of those is firing and the other is exhausting. Only separated by 90 degrees. On a cross plane, the two pistons that are simultaneously at TDC are on opposite banks. A regular firing 4 cycle V8 must fire everu 90 degrees of crank rotation in both cases.

I put a flat plane in my Harley. Both cylinders fire at the same time.

Just nice to have the option now. There is a company working on a design for a flatplane crank for an LSX, Coyote, and SBC. Looks like a kit.

Lower torque levels for a flat plane V8 engine is totally inaccurate. The engine actually makes more torque due to less power loss from rotating a lighter crankshaft. But don’t believe me, just compare the Ferrari 458 Italia’s engine to any other V8 engine around the same displacement.

the flat plain crank isnt the direct reason for the lower torque, its the shorter stroke.

hes just saying that flat plain crank desing V8s normally have shorter stoke.

It’s low end torque. Peak torque isn’t reached until about 6,000 RPM max horsepower is @ 9000 RPM. A flat crank design is for road racing so you can hold your gear through turns. My Chevy 383 stroker has way more torque 475 @ 4500 RPM and about the same horsepower produced at lower RPMs about 6200. For a lot less money to

Anyone who thinks that is not the baddest sounding unit sold in America needs a psych evaluation. If I had to choose between a corvette vs gt350 floor mat I would b walking everywhere

Most ford owners have to walk anyway lmao

Interesting concept… I like it… I wondering how well one would work on an older American V8 (327, 302, 340, etc) with the proper ignition mods and the proper cam… The mind races.

hey Max this is a 90 degree V8 .. not an 180 degree opposed 8

the crank pins are 180 deg no where near 90 deg, and I’m just an automotive student, and I can see that.

[…] The 5.2L V8, which is found in the new Shelby GT350, is the most powerful naturally aspirated Ford V8 ever (over 500 horsepower). It’s also the first Ford production V8 to utilize a flat-plane crankshaft. […]

Back in 1959 I worked on a 1932 Pontiac with a flat plane crank. There was a vibration but the thing went down the road with it’s vibration,like most other old cars.

On a flat plane V -8 where does the “vibration” come from?

[…] Disadvantages: Prone to vibration, lower torque levels. Or you can read the who article: Flat Plane Crankshafts vs. Crossplane Crankshafts 2010 R6 2011 Ninja 250 2012 Ducati 848 Corse SE 2017 R6 (Ordered, arriving March 2017) […]

Less torque from a flat plane crank? What does the crank have to do with torque? Nothing, really, unless you realize that a lighter crankshaft will produce torque *more* effectively.

The larger the diameter of the crank produces more torque, conversely a smaller diameter one will produce less. Just like gearing. 4.55 gearing will have more wheel torque than say 3.27 gears. Also did length also determines combustion and torque effecency. For example, if your using a short handled ratchet (short rod) it takes more torque to turn a bolt (but you can spin it faster once it gets going, faster it goes the more the short rod and high compression offset piston runaway from combustion events) have a long ratchet (long rod) and the piston moves away slower from combustion events, dwells longer at tdc compression, and runs away from combustion events much slower (longer rods need more crank degrees to transmit visible movement).

I’m glad to see Ford coming out with a flat plane v8. It’s the logical configuration for a DOHC setup. What’s the point of putting twin cams on an engine with a heavy cross plane crank? It DOES breathe better because of the greater valve area, will spin a little higher because of the lighter valves, and you do get a hemi at no extra charge with the DOHC, but the whole package is really optimized with the flat plane crank. That allows all the DOHC’s advantages to really shine.

I can’t make sense of the firing sequence for the Coyote. They say it has the same as the old flathead 1-5-4-8-6-3-7-2. That contradicts what some say about the flat plane crank firing LRLRLRlLR. And when I work out the crank throws I always get two cylinders firing together and one 180 rotation with no fire. I mean if 8 and 6 fire in consecutive order in a flat plane crank they either fire together or are 180 degrees out. So does the Coyote have a double punch and a dead spot ? And the only two scenarios I see for the crank layout using that firing order is up-down-up-down or up-up-down-down and not others that are pictured like up-down-down-up.

So how many rotations to fire 8 cylinders ?

Hey Curly, it would be the same for a cross-plane and a flat-plane engine, 360 degrees rotates half of the cycle (for a traditional 4-stroke), so a complete 1-8 cylinder intake/exhaust sequence would be 720 degrees, or two rotations of the crankshaft.

JV,

If you lay out a Ford block / cylinder numbering, it does go side to side.

RM14

1-4 are left bank – 5-8 are right bank. The firing order above has 6 firing after 8 – both on the same side !!! Or Ford has changed it’s numbering convention for the Coyote.

Look at it this way. Number the cylinders 1,2,3,4 on the left; 5,6,7,8 on the right. 1 fires and 5 fires 90 deg. later then 2 and 3 reach tdc at 180 deg. 3 fires and 7 fires 90 deg. later. 90 deg. more and we’re at 360. We fire 4 and 8 fires 90 deg. later. another 90 deg and 2 and 5 are back on top. 2 fires and 90 deg. later 5 fires. another 90.deg and we start again. All 8 have fired one after the other, 90 deg. apart in 2 revolutions. Each bank has the firing order of a 4 cyl., firing every 180 deg. Each cyl.in the right bank fires 90 deg. after its journal mate in the left bank, giving 90 deg. per power stroke.

crank throw #6 is either the same UP/DOWN location as #8 or 180 degrees out. Since 6 & 8 are on the same side, and 6 fires right after 8, it must fire 180 degrees after 8 – and that would leave a 90 degree gap with not firing! That doesn’t make sense.

Also from the firing order it appears that the 1/5 throw is 180 degrees from the 2/6 throw – meaning after 2 fires, the next firing in the 1-5 4-8 6 3-7 2 firing order is #1 and the crank has to turn another 180 degrees to get it up.

Thanks a lot for the great explanation!

SEEMS TO ME THAT TORQUE IS CONNECTING ROD LENTH AND FLYWHEEL WEIGHT. LONGER STROKE AND HEAVY FLYWHEEL IS THE TIRE SMOKER…

Bill – Torque is a force times a distance, e.g. ft-lbs. The force happens on the power stroke when the piston drives the connecting rod into the rod journal of the crank. The distance would be measured from the center line of the crankshaft to the center line of the connecting rod journal, which also determines the stroke. All things being equal, a bigger stroke equals bigger torque. With the inherent vibration of the 180 degree crank, super car engine designers know that a larger stroke will amplify vibrations, so they keep the stroke shorter. Diesel truck engine designers, however, use a larger stroke.

You get more torque from a 90 degree crankshaft because 2 cylinders are firing on the same power stroke.longer connecting rods allow more cylinder filling because it slows the piston speed down.

Do flat plane crank V8 engines always have a 90 degree angle?

[…] have a tendency to be exceptionally loud. Part of that is due to the different engine components, including the crankshaft. If you really want more power, the flat plane crank is an excellent way to get it, but you might […]

Flat plane firing only every 180゚ is only true for an inline engine. On a 90゚ V-engine the firings are 90゚ apart.

So each bank is an even firing four cylinder engine. But 90 degrees off phase with the oposite bank.

Would this not be considered an odd fire engine?

It’s funny to talk about flatplane cars as “exotic cars”, when flatplane engines are by far the most widely used around the world. I know, I know, anything out of the USA is exotic for the average USA citizen.

Regards