Trick Flow Specialties built a 565 cubic-inch Chevy that was awarded to the IHRA Summit Racing SuperSeries Top Class Champion back in 2012. The big block made 1,013 horsepower. That’s a very respectable benchmark, one that Trick Flow wanted to beat with its next engine.

The solution is cubic inches—lots of cubic inches. That’s something easy to do with a Ford 460-based engine. With a 10.320 inch tall deck, generous 4.900-inch bore spacing, thick cylinder walls, and a huge crankcase that can handle lots of stroke, it’s like Ford engineers designed the 460 just for building big-inch engines.

You can go upwards of 800-plus cubic inches with a 460-based engine, but that means aluminum blocks, stupid-stroke cranks (upwards of six inches), and other expensive custom parts. Trick Flow opted to leave those to the tractor-pull and monster truck guys and went with an engine virtually anyone can duplicate with parts from suppliers like Summit Racing.

The cubic inch limit is about 557 with an OE-style 460 block. Ford Racing’s popular siamesed-bore A460 iron block can handle about 598 cubic inches (4.600 inch bore, 4.500 inch stroke) without a fuss, providing a good balance of size, power (especially torque), and parts availability. Thus, 598 is the direction Trick Flow went.

The Parts

Here are the building blocks for the 598:

Ford Racing A460: Made for racing, this block has siamesed bores to increase block rigidity, a plus with large overbores. Other features include four-bolt nodular iron main caps and three inch diameter main journals.

SCAT Standard Weight Crankshaft: Forged from 4340 steel, this crank gets it all—heat-treat, shot-peening, nitride-hardening, and micro-polishing. The internally balanced crank has lightening holes in all rod throws, and large-radius journals for improved strength and wear resistance.

Wiseco Pistons and Rings: Custom-made part for the short block, the forged pistons have a 6.8cc dome that matches up to the combustion chamber shape on Trick Flow’s PowerPort A460 cylinder heads. The rings are low-friction .043 inch top, .043 inch second, and 3mm oil control.

Callies Compstar Connecting Rods: These big block Chevy-sized H-beam rods are forged from 4340 steel. The rods are stress-relieved and have burnished threads and bolt spot faces so part dimensions stay consistent, no matter how many times they are torn down and reassembled.

Ford Racing Roller Cam Bearings: These ultra-low-friction needle roller bearings require so little lubrication that you can actually block off the stock cam oiling holes. This reduces both oil aeration and horsepower loss due to windage.

COMP Cams Roller Camshaft: Custom-ground for this engine, this is a big cam—285/300 degrees advertised duration at .050 inch and .873/.831 inches of lift (with 1.8 ratio rockers). Lobe separation is 114 degrees.

Jesel Belt Drive: The two-piece camshaft belt drive reduces the amount of harmonics being transferred to the camshaft. That means rock-solid cam timing compared to a timing chain or gear drive. It also has an external cam timing adjustment feature that allows you to accurately set cam timing.

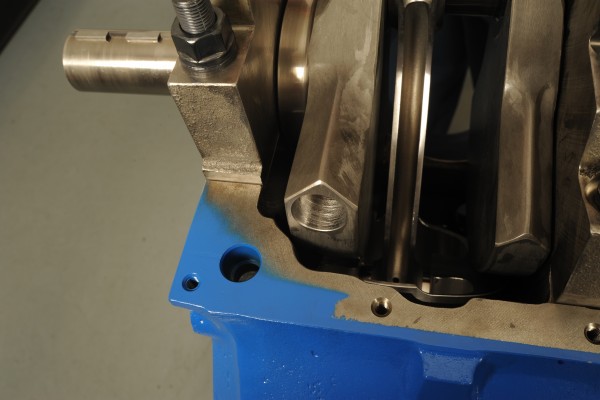

Assembly

Other than some minor machine work (which we’ll cover in the photo captions), the 598 short block was a straightforward build anyone with a decent home shop can handle. We’ve said it before, but it bears repeating: Building a reliable race engine is all about taking your time, keeping things clean and well lubricated, and most importantly, measuring everything at least twice.

Next Time

In the next post, we’ll be finish up the long block—cylinder heads, valvetrain, oiling system, induction, and ignition. We think you’ll like what you see!

Parts List

Wiseco Forged Pistons, set of 8 (special order from Summit Racing)

Callies Compstar H-Beam Connecting Rods, set of 8

Clevite H-Series Main Bearing Set

Clevite H-Series Rod Bearing, each (8 required)

Ford Racing Roller Cam Bearing Set

COMP Cams Roller Camshaft (special order from Summit Racing)

Whats the compression

it still a ford

[…] covered short block assembly in our first post and top-end installation in the second article of this series. That just left carburetion, […]

[…] our initial Big Ford Horsepower post, we told you how Trick Flow Specialties in Akron, OH was building a 598 big block Ford to […]

Nice good job

Can someone tell me the torque specifications on that 598 main caps and rod bearings please

You know you’re close to patent infringement

My name is Rick I’m looking for a 598 big block for dart short block for the street my question is can that motor be built with a 88 turbo if so can I drive it on the street. I’ll only drive it on the weekend and take it to the track. Let me know.