So you just A) bought a high performance engine; B) bolted some go-fast parts on your existing engine, or C) built a brand new engine. Now you’re chomping at the bit wondering how much power you’ll have under your right foot.

There are three basic methods for measuring engine output: testing on an engine dyno, running a vehicle on a chassis dyno, or making passes at a race track. Each will provide valuable information, but the method you choose depends on what exactly you want to know about your engine’s performance.

This post will describe the first two methods since they are the most directly measurable, repeatable, and are conducted under (relatively) controlled conditions. While elapsed time and mile-per-hour results from the track are good indicators of performance, track testing can be influenced by too many variables (track conditions, weather, suspension settings, driver skill, etc.) to be a truly reliable measure of engine output.

Engine Dyno Basics

Engine Dyno Basics

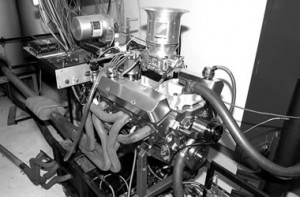

An engine dyno calculates power output directly by measuring the force (torque) required to hold a spinning engine at a set speed (rpm). The dyno software then calculates horsepower based on the torque figure and engine rpm (horsepower equals torque times engine speed, divided by 5,252).

The dyno has a control board that shows readouts of torque, rpm, water temperature, oil temperature and pressure, exhaust temperature, and air/fuel ratio (from an O2 sensor) via sensors connected to the engine. The dyno operator can start and run the engine from the board via a cable-operated lever or electronically, depending on the dyno. The engine itself is usually stripped of its accessory drive (most dynos use an electric water pump and perhaps an alternator for testing) and is fitted with headers and, depending on what the customer wants, a full exhaust system.

Since it measures torque directly, an engine dyno gives you the most accurate picture of how much power your engine makes. As such, an engine dyno is the most accurate way of doing parts comparisons (cylinder head vs. cylinder head, for example) or fine-tuning an engine to extract maximum power. Other advantages of engine dynos include easy access to the engine for swapping parts and tuning, repeatability, and (usually) well-controlled testing conditions.

Chassis Dyno Basics

Chassis Dyno Basics

Where an engine dyno measures power directly from the engine, a chassis dyno measures engine output—or more accurately, drivetrain output—at a vehicle’s drive wheels. In its basic form, a chassis dyno consists of a platform with a pair of drums or rollers, a braking or power absorption system, and software to calculate power output.

The test vehicle is positioned on the dyno with its drive wheels on the drums or rollers. Depending on the dyno type, the software calculates torque output based on how fast the vehicle accelerates the drum (inertia style dyno, like a Dynojet) or via a load cell that measures power absorbed by the rollers (eddy current dyno like a Mustang Dyno unit). Horsepower is calculated from the torque value. Most chassis dynos have the capability to monitor air/fuel ratios (via an O2 sensor in the exhaust) and other engine parameters.

The chassis dynamometer’s claim to fame is the ability to measure power at the drive wheels—the “real world” performance of a vehicle. You can make tuning changes and test parts to find out the effects on power, just as you would with an engine dyno (though not as easily). And since there are standard factors for engine power losses through the drivetrain (15-17 percent for manual transmissions and 20-25 percent for automatics are figures accepted by most tuners), a chassis dyno can give you a good idea of how efficient your drivetrain is.

Which Dyno Do I Use?

So which dyno is better? The answer, of course, is it depends. If you want to break in and tune a new engine, compare the effects of different parts on power, or extract maximum power from a current engine combo, the engine dyno is the way to go. Because it measures “true” engine torque, monitors a wide array of engine functions, and tests under controlled conditions, an engine dyno provides very accurate and repeatable results.

Determining the overall performance of a vehicle’s drivetrain is where the chassis dyno really shines—after all, the power at the drive wheels is what ultimately moves your vehicle down the road or around the track. Perhaps the biggest draw of a chassis dyno is that you don’t have the time and hassle of yanking the motor out—just drive up on the platform, make some runs, then drive home with some power printouts in your hand.

The thing to keep in mind about a chassis dyno is that it really isn’t designed to measure true, or flywheel, engine output. You have to determine the amount of engine power consumed by the drivetrain and add that to the drive wheel power figure. While there are generally accepted loss percentages for manual and automatic transmission-equipped drivetrains, they are really only estimates. Add in the fact that drivetrain losses can vary from one run to the next, and things like tire temperature and pressure also affect final results, and you can see a chassis dyno is much better suited as a vehicle tuning tool than an engine horsepower measurement tool.

Consistency is Key

No matter which type of dyno you use, you need to understand that consistency is the key to accurate results. A typical dyno test session consists of multiple pulls (engine dyno) or runs (chassis dyno), not to mention numerous adjustments and wholesale parts changes. To make the results valid, testing conditions—temperature, humidity, dyno type, operator, and procedures—need to be as consistent as possible.

Ventilation is also critical, especially for chassis dynos. Poor ventilation allows exhaust gasses to contaminate the intake air charge—not good for power or repeatability. Make sure the shop that you are using has adequate ventilation, or wait several minutes between pulls for the exhaust gas to disperse. Any deviations in testing conditions can impact the results and leave you with the wrong impression of what your engine or vehicle is truly capable of.

One final note on dyno testing: shop carefully for a qualified dyno operator. Just because someone buys a dyno and hangs a sign that says “Dyno Tuner” doesn’t make them an expert. Ask around and find out which shops people use, then pay a visit to see how they operate. Going on a day when a test session is scheduled is ideal; you can get a good feel for a dyno operator’s tuning skills, customer service, and things like shop cleanliness and organization. After all, it’s your hard-earned money—and your prized possession—that you’re putting in someone else’s hands.

Thank You 4 the info.

Good info

info para tener en cuenta 😉

[…] your vehicle’s maximum horsepower (Max. HP). You can determine this by having your vehicle dyno tested or by making a reasonable horsepower estimate based on the manufacturer’s advertised […]

[…] very basic website which talks about dynos and expected results. The last paragraph is important: Dyno Testing Basics: Engine Dynos vs. Chassis Dynos IF your ecu is actually not a stage1, Syked can make it into one for $99 including the vin […]

[…] not the deepest but probably the easiest and most concise of the lot for a cursory understanding. Dyno Testing Basics: Engine Dynos vs. Chassis Dynos Current rides: 2016 Ducati Panigale 959 (Arctic White) 2016 Ducati Monster 1200 R (Badass […]

Need real numbers for what the HP % loss is for a 4 cyl, 5speed, mid engine, rear 2 wheel drive. Front wheel drive should be the same, I think. Number needed from someone that has both engine dyno, and chassis dyno, on the same car. I have tons of chassis dyno tests for the car I am working on, no engine only dyno results. Want to use a sim program for engine development, so the % of loss needs to be very close to real world. Typical “about” % numbers is not specific enough.

Trying to understand chassis dyno tests and reaching full rear wheel horsepower at much less than the peak gross horsepower rating of an engine. Imagine and engine has 325 gross horsepower at 4600 RPM. The rear wheel horsepower is 135 at 3100 RPM. How could a peak rear wheel horsepower be reached at 3100RPM. This particular example is for a 1950’s car.

Thx for reading this.

Jim

Thanks for explaining what a chassis dyno is and how it measures the power. Lately, my brother is really into cars and everything that has to do with them. I’m going to share this article with him so he can have more knowledge about how a car’s power is measured.

Thank you for explaining that the typo of dyno that we should use depends on the outcome we plan on achieving. My brother just bought a motorcycle and he would like to test out his horsepower since he has just increased its performance. I will inform my brother to go with an engine dyno when he visits the auto shop.

I appreciate your message of concern when you say to shop carefully or a qualified Dyno operator. I am thinking about having my car tuned for Christmas. Kind of a gift to myself because COVID will make it hard to actually get gifts in person from anyone else.

that is good