As 3.5L EcoBoost-powered 2013-16 F-150s have begun to rack up 150,000 miles or more, wear and tear have become increasingly common with its turbocharger system.

While Summit Racing may not be the first to offer a complete turbocharger replacement kit for the 3.5L EcoBoost V6, it did set out to develop an option that would address common issues in these applications differently (and potentially more effectively) than existing kits.

Design engineers paid particular attention to manifolds and gaskets.

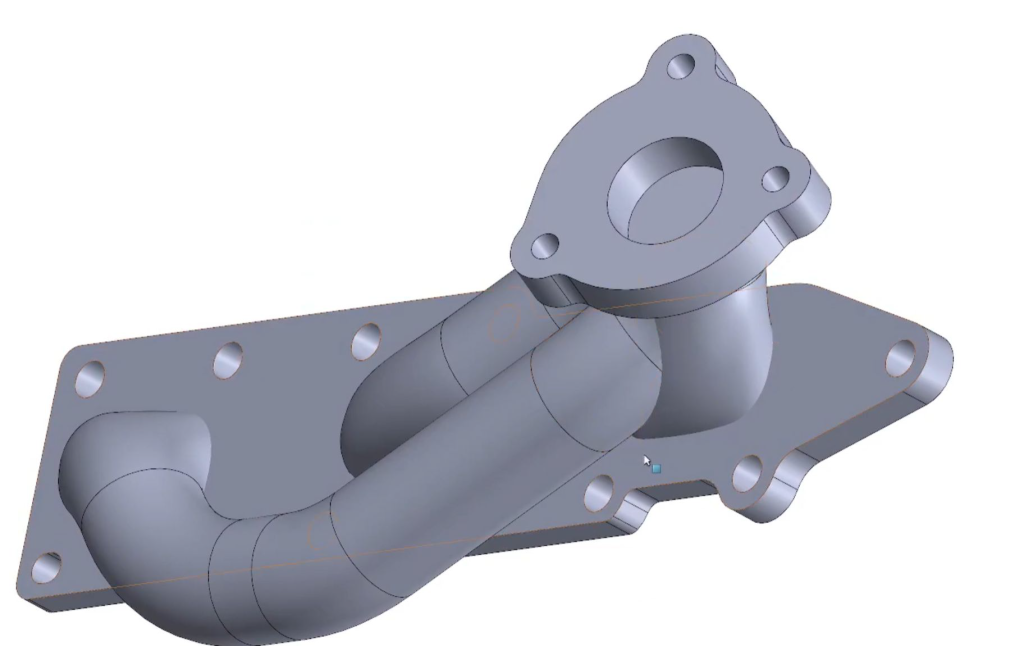

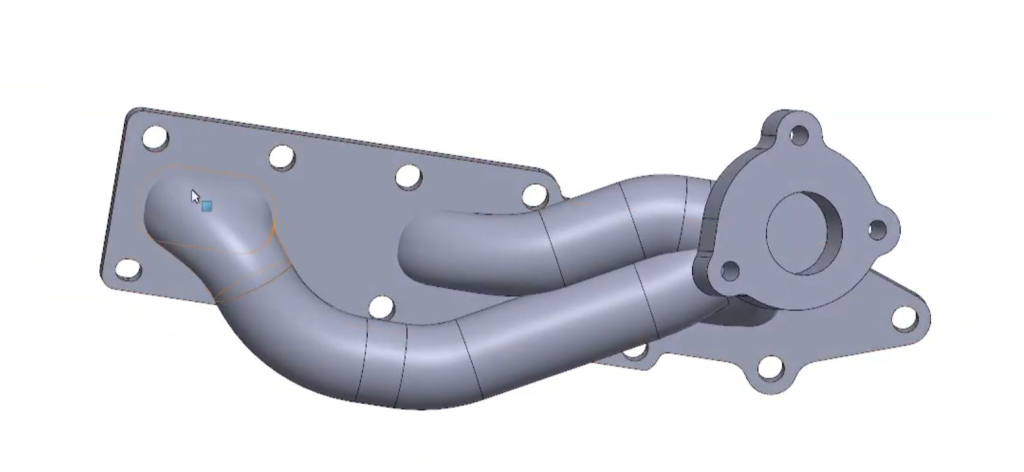

The Manifold Design

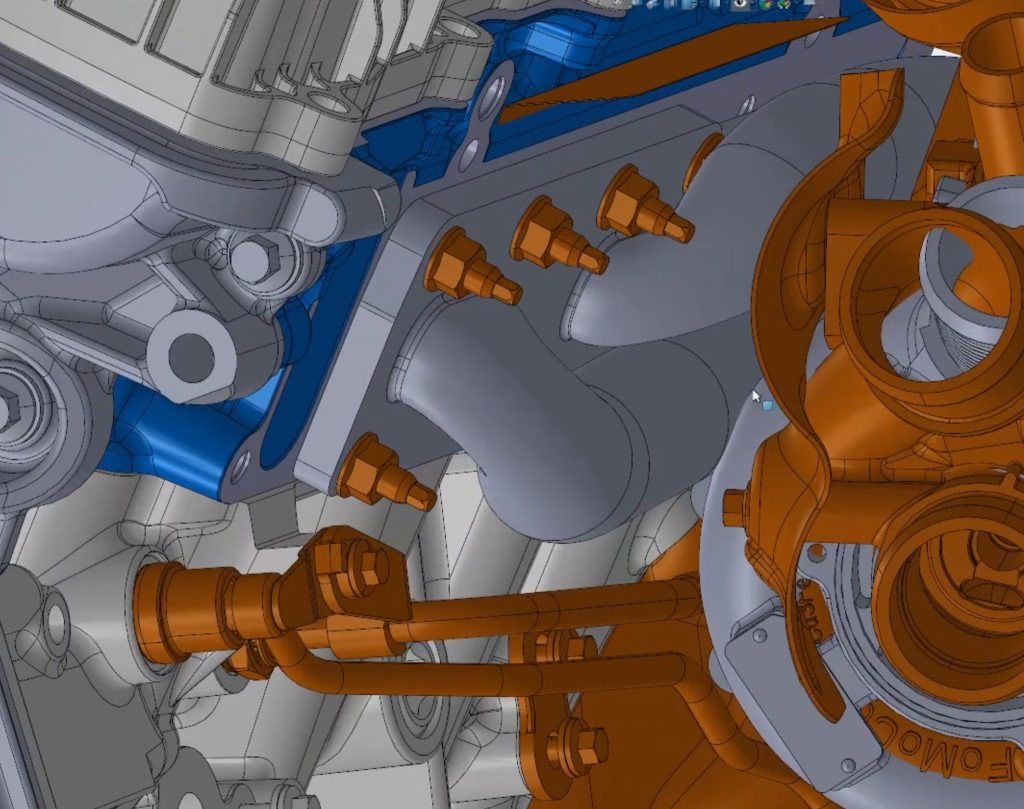

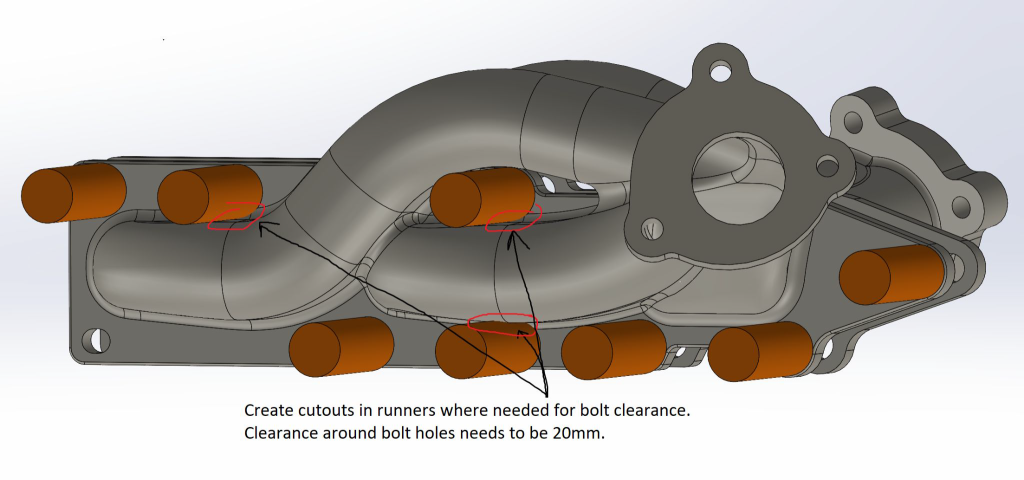

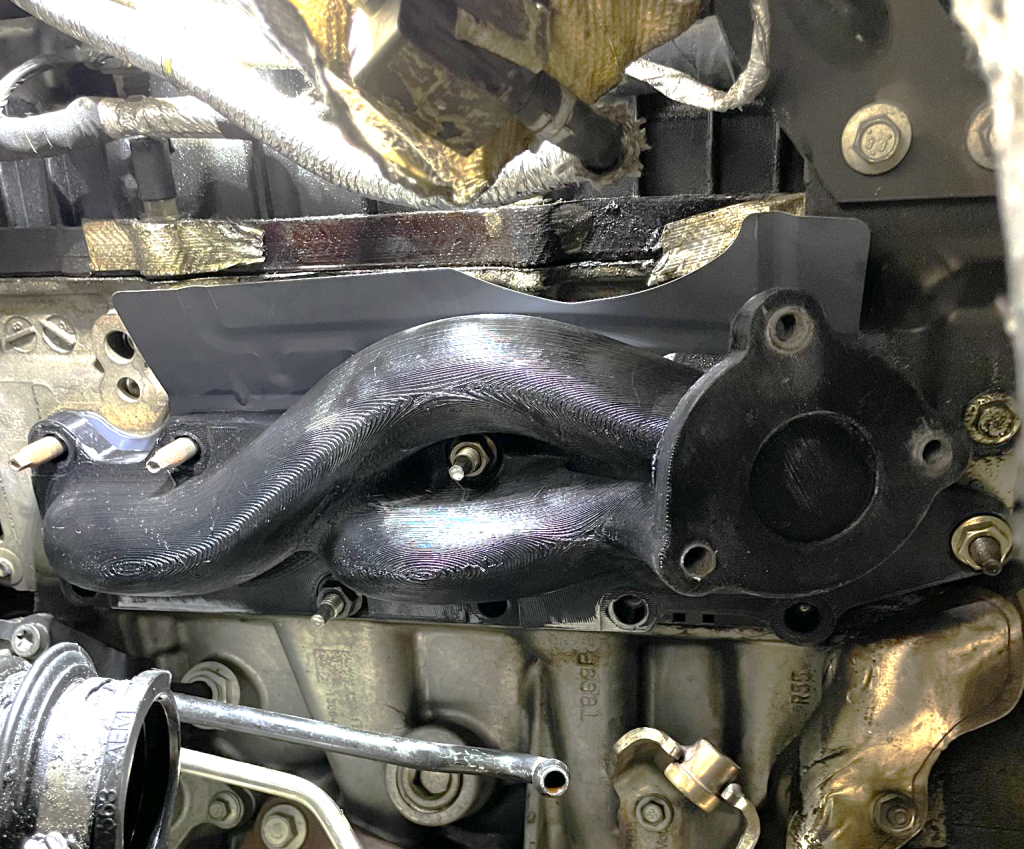

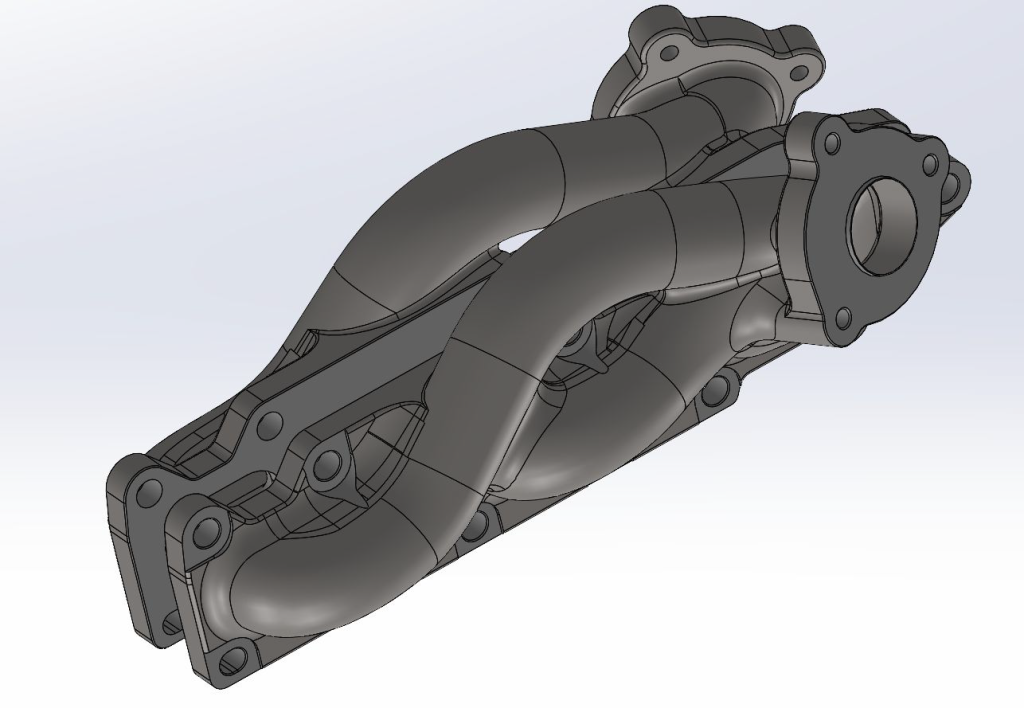

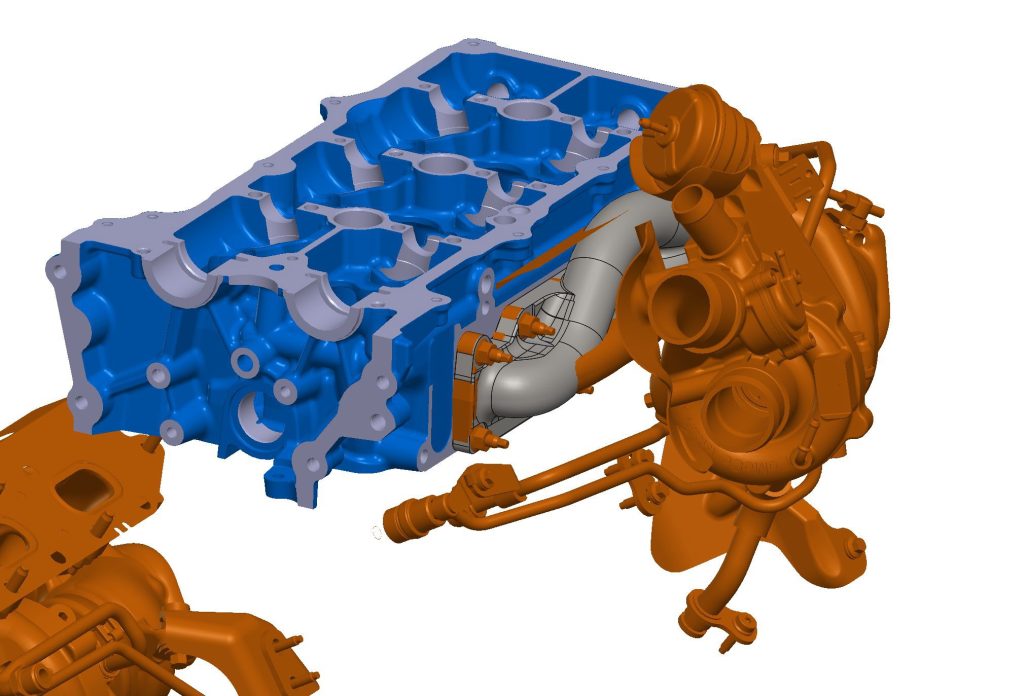

Several design iterations were made to find the optimal manifold routing to provide the most clearance possible. The initial prototypes were received and installed onto a 2012 F-150 test vehicle.

The initial design concepts shown above intended to route the forward most runner below the manifold; however, there were clearance issues with larger aftermarket turbos, coolant/oil lines, and manifold stud clearance.

The final configuration was developed using SEMA data and 3D printed versions of the manifold.

This eliminated the clearance issues and enabled engineers to create a port-matched design that’s optimized for better exhaust flow.

Real-World Testing & Continual Refinement

These manifolds were installed and run for approximately 500 miles before being removed from the vehicle for inspection.

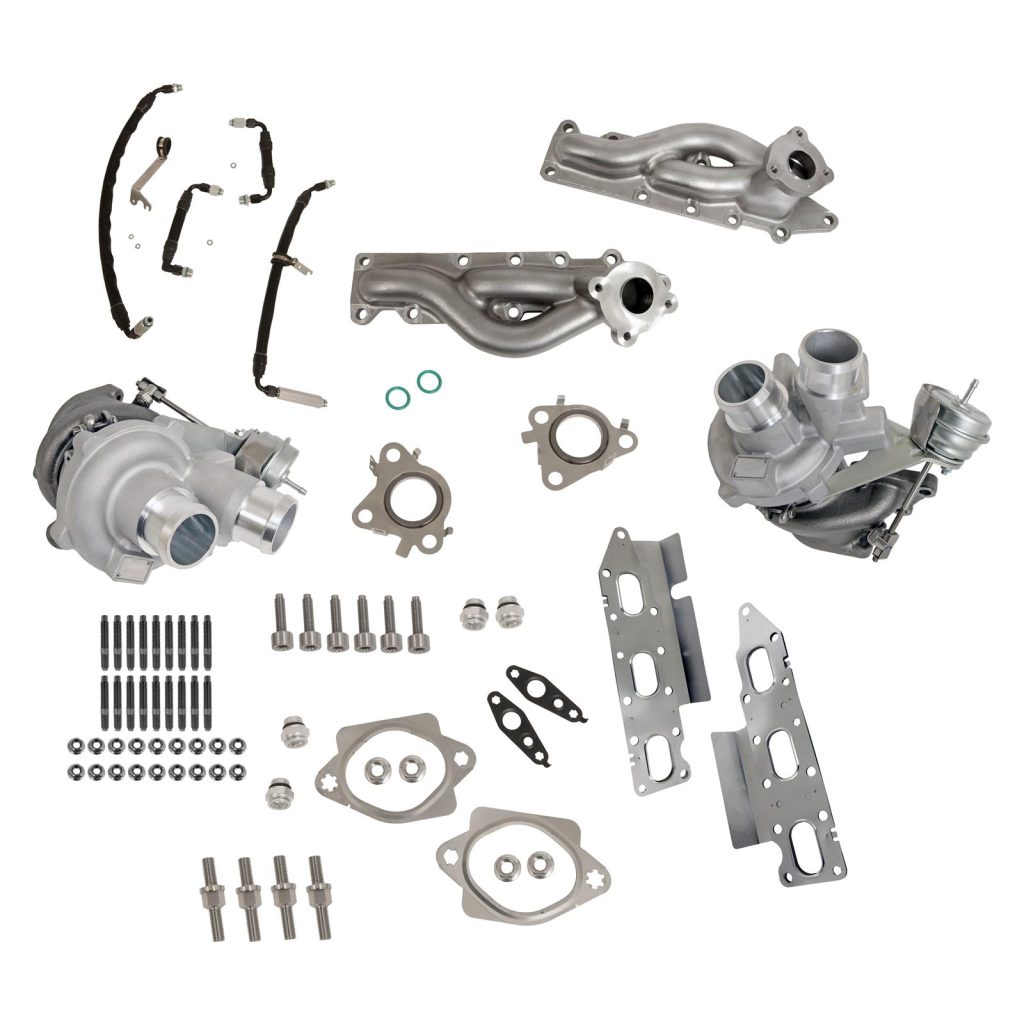

After teardown, issues were recorded with the turbocharger gaskets being pulled into the outlet of the manifold, due to the significantly larger outlet compared to the stock manifolds. To address this issue, a machined lip was added to the outlet of the manifolds to locate the gasket during installation as well as prevent the gasket from extruding into the exhaust flow path.

This does a better job of keeping the gasket in place compared to the existing (and very loose) locating feature on the turbocharger. When installed properly, the machined lip ensures it is almost impossible for the turbocharger gasket to be misaligned to the exhaust manifold.

Because the lightweight stock manifolds are prone to warping and cracking, Summit Racing opted to use CF8 stainless steel for its replacement EcoBoost manifolds. CF8 is the cast equivalent of 304 stainless steel and delivers the best cost-to-benefit ratio among cast stainless options. It offers strong corrosion, fatigue, and high-temperature durability without the added material cost of higher-alloy grades.

While the factory ductile iron manifolds can operate well to temperatures of 300 to 350° C (570 to 660° F), CF8 can operate mechanically up to 425 to 550° C (800 to 1,020° F) and withstand oxidizing environments up to 870° C (1,600° F) without significant degradation. CF8 also maintains higher ductility than ductile iron, meaning it delivers superior resistance to cracking under thermal cycling and vibration.

Bottom line? For EcoBoost applications, the combination of elevated-temperature capability, corrosion resistance, and ductility of CF8 stainless steel significantly reduces the likelihood of future failures caused by cracking, fatigue, or thermal warpage.

Upgraded Gaskets

The factory gaskets were another area of focus for improvement.

The OE manifold gaskets are prone to leaking. In order to outperform the factory parts in form and function, the Summit Racing kit comes with high grade 316 stainless steel gaskets. This has superb corrosion resistance and high heat cycle performance.

The port shaping and profile is retained for optimal flow for OE and aftermarket high horsepower applications while also creating an optimal seal between surfaces. The four-layer composition offers enhanced sealing during expansion and contraction of materials during normal to extreme duty cycles.

The Summit Racing EcoBoost Turbocharger Replacement Kit also comes with new (not remanufactured) turbos that are direct-fit replacements for the factory components. Plus, it includes new coolant lines with threaded AN fittings and adapters. This makes the lines less prone to leaks or rust.

By analyzing the weak points of the factory Ecoboost turbo setup and making some well thought-out choices in design and materials, Summit Racing can help give your EcoBoost new life—and ensure it operates even better than before!

***

Learn more about these kits here:

Comments