I’ve used a blow gun to blow air past the little hole in the primary venturi on my Holley vacuum secondary carburetor. This barely opens the secondaries and it is not very consistent. I have checked the diaphragm and it holds vacuum perfectly. I’ve also sucked on it with my mouth and it opens very easily. I cannot figure out what’s going on with the carburetor that it would not send a strong signal using a blow gun or when the engine is running. It just opens the secondaries a little bit on wide open throttle.

E. P.

This is a fairly common situation with Holley vacuum secondary four-barrel carburetors. Since you didn’t include any description of your engine or the size of the carburetor, we’ll use a 350ci small block Chevy with a 750 CFM Holley carburetor as an example to answer your question.

Secondary throttle opening is controlled by a vacuum secondary diaphragm. It’s a pretty simple mechanism. Inside the housing is a rubber diaphragm that is linked to the secondary throttle shaft. A spring applies pressure to the top of the diaphragm to keep the secondaries closed. When a vacuum signal from the primary side of the carburetor is applied to the top of the diaphragm, it will overcome the spring tension and slowly open the diaphragm. That allows the secondary throttle plate to open.

To make this work, you need enough air velocity through the primary side of the carburetor (aided by velocity from a secondary side vacuum signal) to create sufficient vacuum in that little hole in primary venturi you mentioned. The more air that moves through the primary side, the higher the air velocity. This provides a bigger signal to open the secondary diaphragm.

If there is insufficient velocity on the primary side, the secondary throttle plate may only partially open. Your test probably didn’t generate enough of a signal to overcome the spring load on the diaphragm. However, this does not mean that the secondaries are not opening when the throttle is wide open at higher engine speeds.

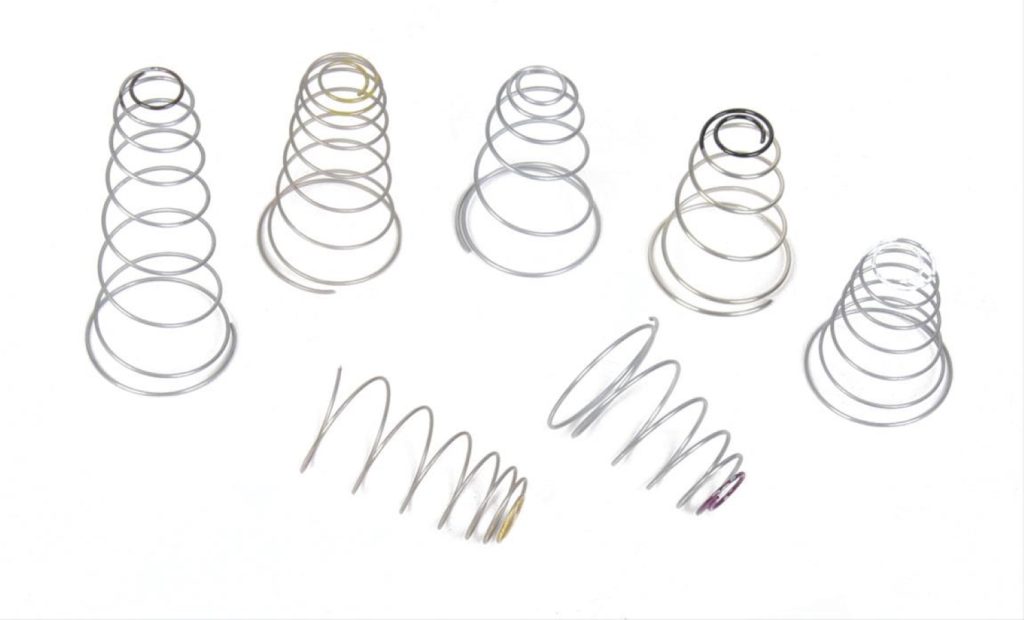

You can change the secondary diaphragm opening point by using a spring with a different tension rating. The chart below from the Holley carburetor catalog details the tension of available springs. It shows the engine RPM where the secondary begins to open and the RPM when it is fully open.

All vacuum secondary Holley carbs come from the factory with a black spring. Note that it prevents the spring from fully opening, and that all springs heavier than the purple one require very high engine speeds (over 8,000 RPM) to fully open.

Holley Secondary Diaphragm Spring Loads and Opening Ranges for 350ci Engine

- White, lightest load

- Yellow (short), lighter load, 1,620 RPM initial/5,680 RPM fully open points

- Yellow, light load, 1,635 RPM initial/5,750 RPM fully open points

- Purple, medium-light load, 1,915 RPM initial/6,950 RPM fully open points

- Plain, medium load, 2,240 RPM initial/8,160 RPM fully open points

- Black heavy load, 2,720 RPM initial opening rate, does not fully open

The chart does not account for actual airflow through the engine (in CFM). We will assume the 350ci engine in question is closer to stock than it is to a fully built competition engine. More air will flow through a very high performance engine, which will lower the secondary plate opening and closing points.

It’s worth noting that just because the secondary throttle plate doesn’t open fully doesn’t mean the engine is starved for air. A mild 355ci engine might only need 600 to 650 CFM of air to make maximum power. This means that a 750 CFM carburetor with fully open secondaries will probably not provide additional power.

Using a lighter diaphragm spring to lower the RPM point when the secondary plate begins to open can improve performance. You want a spring light enough to open the secondaries sooner but not too light that it will create a hesitation or bog. That happens because vacuum secondary carburetors don’t have a secondary accelerator pump squirter to add more fuel. In our experience, the purple or plain springs work the best in most applications, so try those first.

Changing Secondary Diaphragm Springs

Swapping the secondary diaphragm cover for a Holley Quick Change Cover will make changing the spring easier. It has a removable center that allows you to change springs without removing the entire cover and potentially damaging the thin rubber diaphragm.

The hard part of the conversion is keeping the diaphragm in place during reassembly. The trick is to use a vise to lightly clamp the diaphragm rod in place in the lower housing. This will keep the diaphragm sitting flat. Place the top cover and the spring over the diaphragm and carefully start all four screws one at a time. We like to lube the screws with a shot of WD40 to prevent them from grabbing an edge of the diaphragm and tear the rubber. Refer to the photos to see how this is done.

Parts List

Holley Secondary Diaphragm Spring Kit HLY-20-13

Holley Quick Change Diaphragm Cover HLY-20-59

Comments