There’s a surprising amount of overlap between automotive enthusiasts and watercraft enthusiasts. And whether your vessel of choice is a ski boat, bass boat, pontoon boat, or cabin cruiser, there’s a good chance you’ve got an upgraded truck to pull it with or a hot rod parked in a nearby garage.

That said, although many of us are well-versed in engine maintenance for a street vehicle, when you add water to the mix, those regular service demands change significantly.

So we invited some boating experts with Quicksilver Products to help us understand what those nuances are, and elaborate on key facets to consider when taking care of a boat engine—be it an inboard, outboard, or stern drive. (Since Quicksilver is part of the Mercury Marine family, these folks know an awful lot about keeping a boat running well season after season.)

You can listen to the whole OnAllCylinders Podcast interview in the embedded player here, and we’ll also include some snippets from our conversation below as well.

***

Essential Boat Motor Maintenance with the Experts at Quicksilver

***

What’s so Different About a Boat vs. a Street Engine?

“The operating environments for marine and automotive engines differ significantly, both in terms of the mechanical demands and environmental exposure.

“Automotive engines are typically paired with multi-speed transmissions and operate under relatively light loads. And as a vehicle accelerates, the transmission shifts through gears to reduce engine RPM, allowing the engine to run efficiently at lower speeds. Additionally, cars benefit from low rolling resistance tires and operate in relatively controlled environments.

“In contrast, most marine engines are coupled with single-speed transmissions or out-drives and are tasked with pushing a hull through water.

“Marine engines are engineered to operate at near wide open throttle for extended periods of time as well. They have to withstand harsh environmental conditions, including high humidity and in most cases, saltwater exposure. So as a result, both internal and external components must be built to a much higher durability standard to ensure long-term reliability and corrosion resistance.”

So a Boat Motor has Unique Maintenance Demands, Right?

“Just like any machine, your boat needs regular maintenance to stay in top shape. A great place to start is your owner’s manual. The manufacturer puts a ton of thought into building a maintenance schedule that’s specific to your engine and setup.

“Here in Wisconsin, our boating season may be a little bit shorter than in other places. But that doesn’t mean we get a pass on upkeep. Even though we’re not racking up a ton of hours on the engine, time still takes a toll. So you still need to change your oil, replace fuel filters, and keep an eye on the wear and tear.

“Marine environments are especially tough when it comes to fluids. Between the damp air and constant humidity, things like oil, coolant, and other fluids can break down way faster than you’d expect. That’s why keeping your fluids fresh isn’t just good maintenance. It’s essential for these engines.”

What’s Often Overlooked with Regular Boat Motor Maintenance?

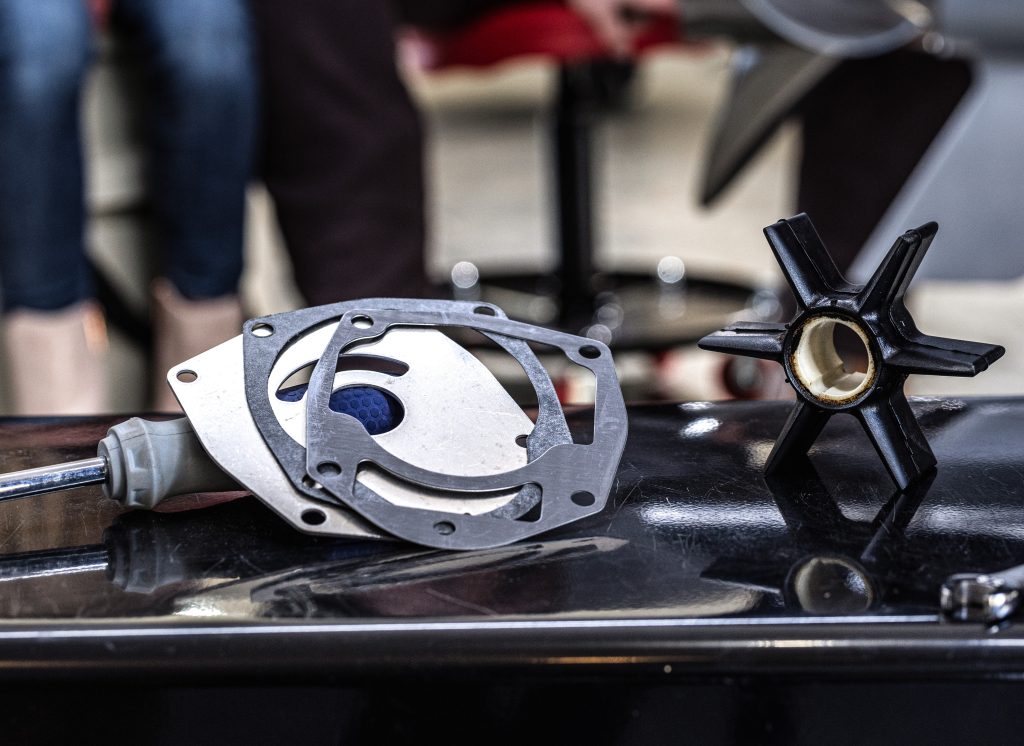

“One of the most neglected parts I see is the impeller. This is a small but mighty part that pumps seawater through the engine. That impeller takes a beating, especially if you’re running your boat through sand, silt, or other debris. Keeping that impeller in good shape is key to making sure your engine stays cool and runs smoothly.

“And also when you’re done for the day, flushing the engine is super important, especially if you’ve been in those murky conditions or salt water. Flushing helps keep all that gunk out of the engine before it dries and becomes a permanent problem in the engine.”

What is an Anode & What Does it Do?

“So as we’ve talked about, marine engines are in kind of a harsh environment, and they’re in water a lot. Both saltwater and freshwater can both cause corrosion to metal parts, and in order to prevent this damage, we offer anodes.

“Anodes act as a sacrificial metal part, and they’re designed to corrode instead of the critical engine part. So there’s some chemistry involved there. But essentially, we want to make sure that the parts on the boat that are corroding are these anodes, which are easy to replace rather than the critical engine parts.

“Saltwater is going to be more corrosive than freshwater. And because of this, there are two types of metals that Quicksilver uses for anodes. Primarily, we’re using aluminum and we’re using magnesium. So aluminum anodes are used in the more corrosive saltwater environment, while magnesium is preferred for freshwater.”

Is There a Difference in Regular Oil vs. Oil You’d Use for a Boat Engine?

“When it comes to oil, there’s really two different applications. There’s PCMO, which stands for ‘Passenger Car Motor Oil’ and then there’s a marine oil. It may seem similar, but they’re very different.

PCMO is for cars, SUVs, and light trucks, with a focus on fuel economy and emissions, and are usually thinner in grades as well. Marine oils, on the other hand, are built specifically for a marine environment. They prioritize durability, protection in the harsh environments, salt water, heat, and heavy loads. So they’re typically thicker and packed with additives that are ‘marinerized’, as I would call it, to go in those outboard and stern drives.

“Because of their specialty chemistry, marine oils usually cost more and they’re essential for keeping the engine safe in these conditions where car oils were never meant to handle. So for boat owners, choosing the right oil comes down to protection of the engine from these tough demands.

“Always start with the engine manual. We’ll say that over and over. Use the recommended type and viscosity in those manuals.

“The takeaway here is don’t swap in automotive oil just to save a little money. Marine oils are formulated for constant high RPM, extreme pressure, and exposure to water. Using the wrong oil can shorten the engine’s life and lead to costly damages.

“For example, a car running at 60 mph, I mean, that’s like a high-speed boat, right? You’re usually at 2,000 RPM, where a boat running at 30 mph is at about 5,000 RPM. So you can see the difference in the load and the demand for marine versus automotive. So the environments are totally different and you need the oil to support them.”

What are Some Tips on Winterizing a Boat for Long-Term Seasonal Storage?

“Any time your boat’s going into storage, preventative maintenance is key.

“One of the most important things is making sure you’re getting all of the water out of that boat package. Running marine safe antifreeze through the engine helps to make sure that there aren’t any hidden pockets of water that could freeze and cause expensive damage while that boat is sitting in storage.

“And don’t forget about the other systems that are onboard your boat too. You’ve got live wells, bilge pumps, water heaters, and other systems that use sea water. They all need to be flushed out.

“Even if you are in a warmer climate, where freezing isn’t an issue, still running a marine-safe antifreeze through those systems helps to provide corrosion protection while that boat sits in storage.”

How Do You Inspect a Boat Propeller?

“Props play a huge role in how your boat performs, so it’s worth giving them a little attention now and then. First things first, grab a pair of gloves because if your prop has hit a rock or something hard underwater, the edges will get razor sharp. So don’t touch it without gloves on. You’re asking for trouble.

“Start off with a visual inspection of that prop. Look for any dings, chips, missing pieces. You know, even a small bit of damage can throw off the balance of the prop, which will lead to poor performance and annoying vibrations while you’re out on the water. Also, don’t forget to check that the prop nut is properly torqued. Again, your owner’s manual will have the correct specs or even instructions with one of the prop kits, hub kits. Just checking the torque on that nut is just a good quick check that can save you from big issues down the road there.

“You can also get a really good sense of your prop’s condition by how your boat performs out on the water. When everything’s working like it should and your boat is lightly loaded, you should be able to hit the wide open throttle range listed on your engine’s information tag.

“If you’re not reaching that range, it could be a sign that something’s off—maybe your prop is damaged, maybe it’s the wrong pitch, or even another mechanical issue that’s affecting performance. But this quick on-the-water test is an easy way to spot potential problems before they get worse.”

Do You Have an Tips on Prop Replacement?

“There’s a huge range of replacement boat props out there, with different diameters, pitches, blade counts, and materials. Honestly, it can all be really overwhelming.

“The best place to start would be just take a look at your current prop. Most of the time, the boat builders do a really good job at matching the right prop to the boat. So your existing prop is probably a really solid reference point. If you can find any part number stamped on it, that’s often the easiest way to track down a direct replacement.

“Also, when you’re changing your propeller, there’s also a really good chance that the hub kit itself will need to be replaced as well.”

What About Any General Boat Maintenance Tips?

“One of the easiest things to forget—and one of the most important—is the drain plug. You know, the big plug right out of the back of the boat. That little piece of brass will make or break your day.

“So we all know how important the drain plug is for keeping water out of your boat while you’re out on the lake—but when your boat’s on the trailer, leave that drain plug out. If your boat’s stored outside and rainwater or snow melt gets in, by leaving that plug in, you just turned your boat into a giant bathtub.

“And yeah, all your gear, all your fishing gear, all your tools, whatever you left in the boat is now floating inside of your boat. So it’s just a simple habit that can save you a ton of cleanup and frustration.

“Probably one of the last things, but definitely not the least, is the batteries in your boat. The boat batteries have a tough job, and they need a little attention too. You need to inspect all your connections, make sure that there’s no signs of any corrosion, and make sure that everything is clean and tight. A loose or corroded connection can cause all sorts of electrical issues while you’re out on the water.

“It’s one of those things that could strand you out in the middle of the lake, ocean, you know, wherever you’re boating. Just load test your batteries, make sure that they’re still healthy. Make sure that they hold a charge like they should. And if you’re going into storage where the boat’s going to be sitting for a long time, consider using a good quality battery tender.”

Any Closing Thoughts on Boat Maintenance?

“Don’t forget your trailer—we’ve all been driving down the road and seen a boat trailer sitting in a ditch. It happens all the time.

“You cannot enjoy a day on the water if you can’t even get to the launch ramp. So it’s just the easy stuff. Check your tire pressure, look for cracks and dry rot. Your trailer sits all the time. It’s probably sitting out in the sun. Tires degrade over time. So just keep an eye out.

“And your wheel bearings on the trailer too. If your trailer has a greasing system on it, use it. That trailer is going in and out of the water, water gets into those bearings, causing corrosion and damage.

“The last thing you want to do is be stuck on the side of the road waiting for a tow.”

***

You can catch the full interview in The OnAllCylinders Podcast section, where you’ll also find dozens of other episodes featuring famous celebrities, friendly gearheads, industry veterans, and really (REALLY) smart technical experts.

Comments