The question on the table: Do supercharged motors respond to wilder cam timing, or does all the boost just get blown out of the exhaust valve from the dreaded overlap?

Spoiler alert, bigger cams that make more NA power also make more power under boost.

Fear not, we won’t let that stop us from showing the dyno results of cam tests run on two different test motors (a SBC and LS) equipped with Vortech superchargers.

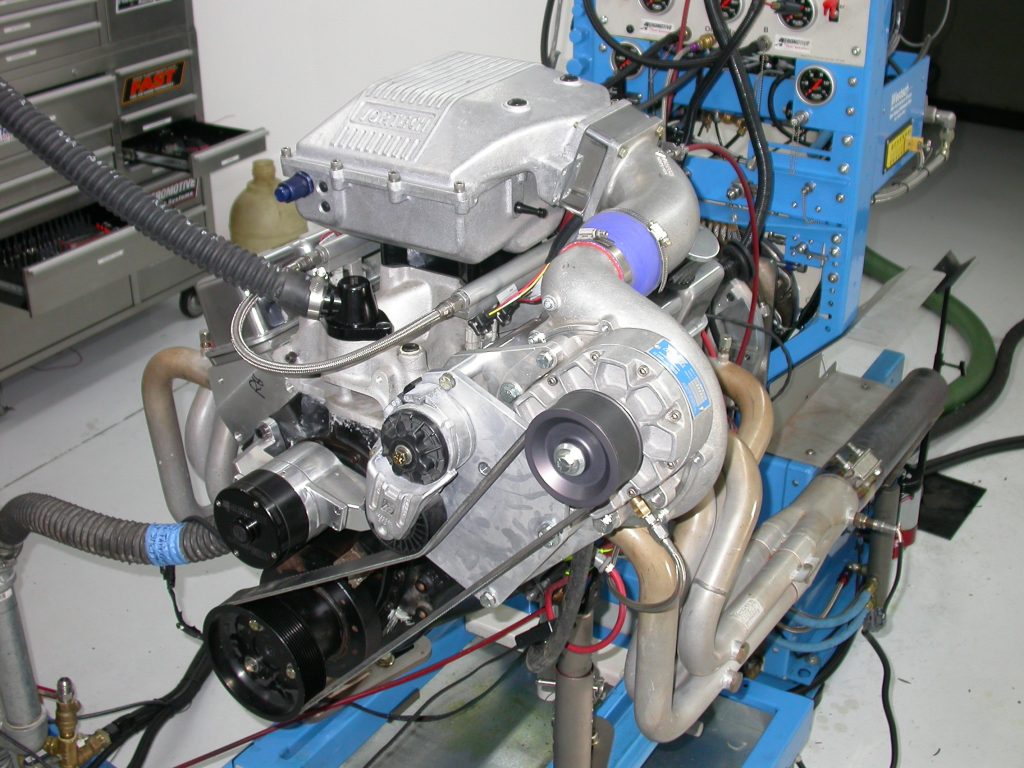

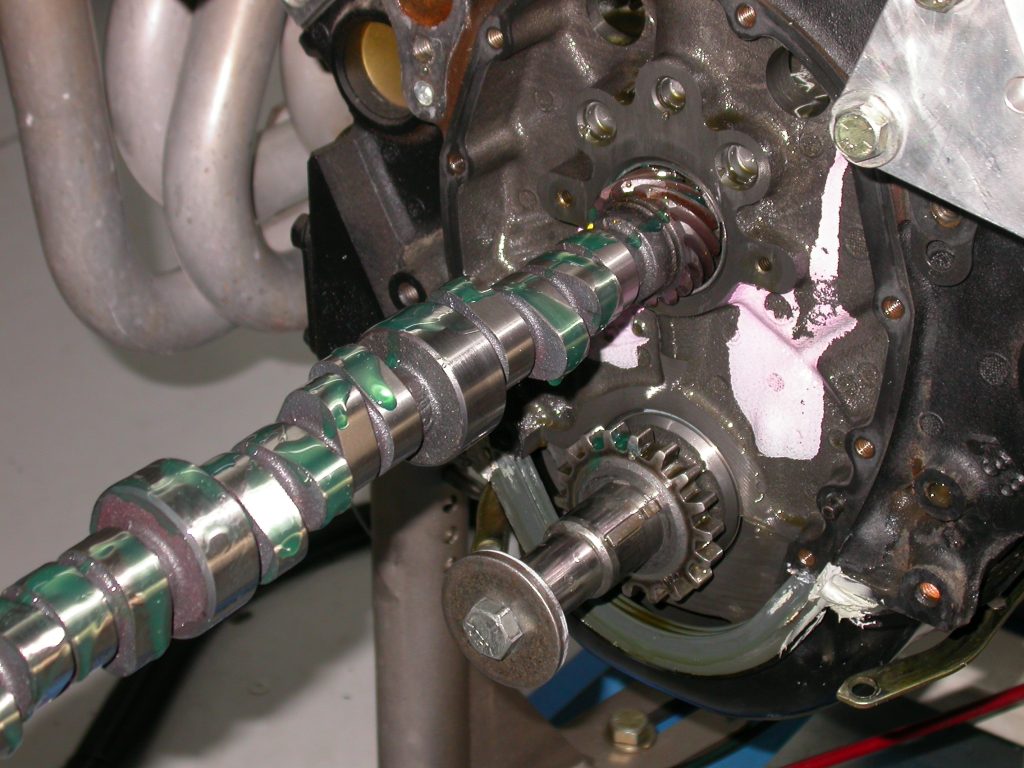

Test motor number one was sourced from the (where else?) junkyard. The L31 Vortec motor was a 350 small block named for the Vortec-style cylinder heads, the late-model small block offered a one-piece rear-main seal (less prone to leakage), the high-flow (best flowing factory heads) Vortec-style heads, and a hydraulic roller cam. Though the stock (truck) cam was plenty mild, the factory hydraulic-roller set up meant we could easily upgrade to a profile with aggressive ramp rates that provided even more power than your average flat-tappet cam.

For our supercharged test mule, we chose two different hydraulic roller cams from Comp Cams, the smaller of the two being an XR258 that offered a .480/.488 lift split, 206/212 degree duration split, and 112 degree LSA. The larger of the two cams was the XR282HR cam that offered a .510/0520 lift split, a 230/236 duration split, and a 110 degree LSA.

Let the Test Begin

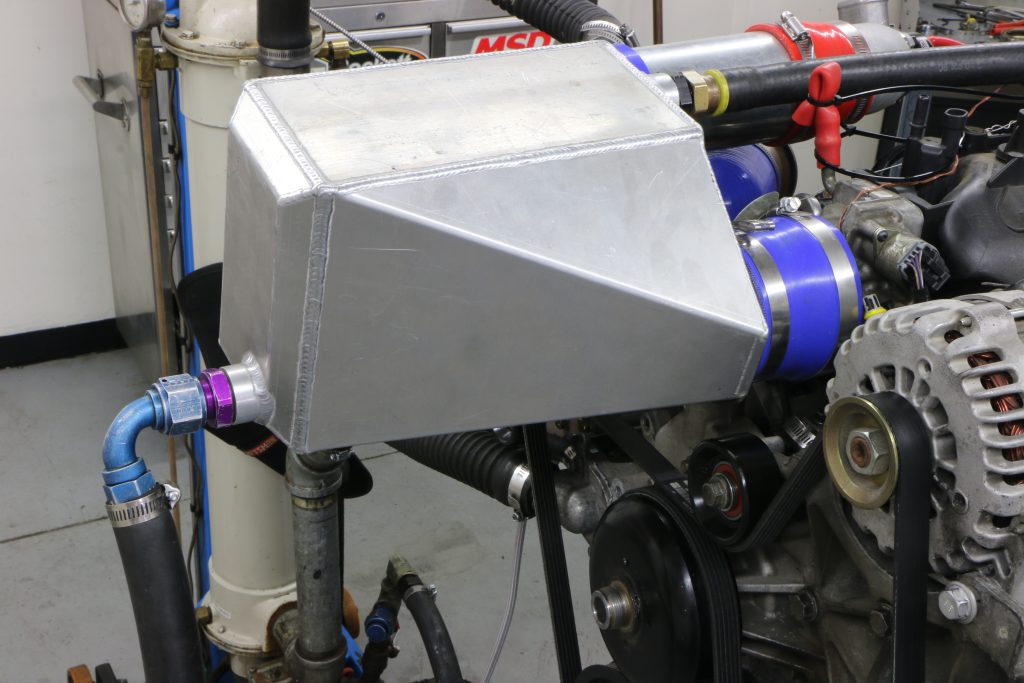

The cam test could have been run with the stock Vortech iron heads, but the 350 had been previously upgraded (tested) with a set of 195cc aluminum heads. The heads were equipped with appropriate dual springs for use with the larger of the two cams. The new heads and cam were fed by a single-plane, Edelbrock Victor Jr. intake equipped with provisions for port EFI. The EFI intake was combined with a set of 36 pound, FAST fuel injectors, and Accufab 4150, 4 hole throttle body.

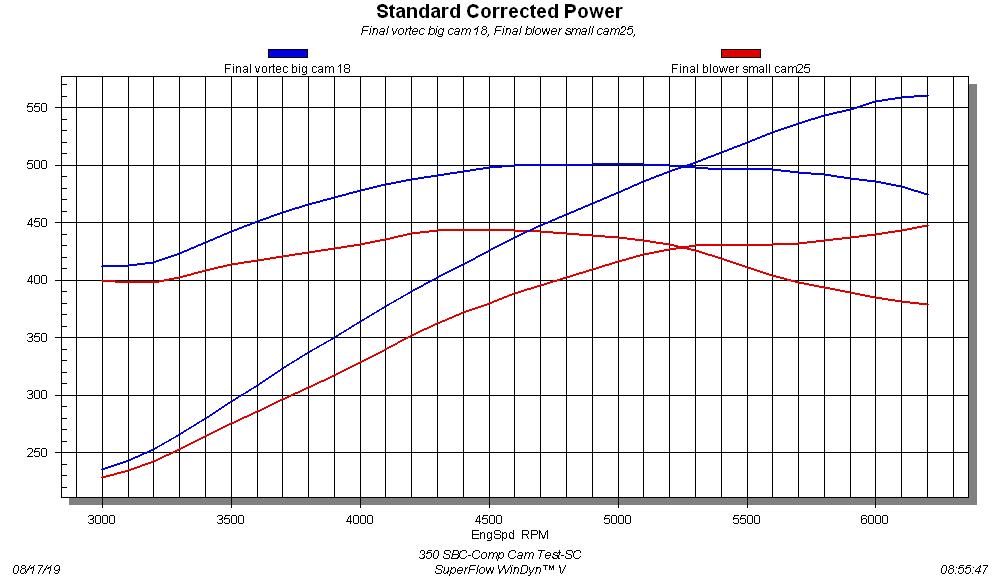

Run with a 6 inch crank and 3.33 inch blower pulley, the S-trim Vortech produced a peak boost pressure of 8.1 psi with the 258 cam. This resulted in peak power numbers of 451 hp and 443 lb.-ft. of torque (a gain of roughly 100 hp over the NA combo). After installation of the larger 282 cam, the peak numbers jumped to 561 hp and 501 lb.-ft. of torque, despite a drop in peak boost to 7.1 psi.

Looking back at the dyno results, we suspect an issue with the boosted small cam run, but know that a bigger cam (even with increased overlap) that makes more NA power will also result in more boosted power.

The 5.3L LS Test

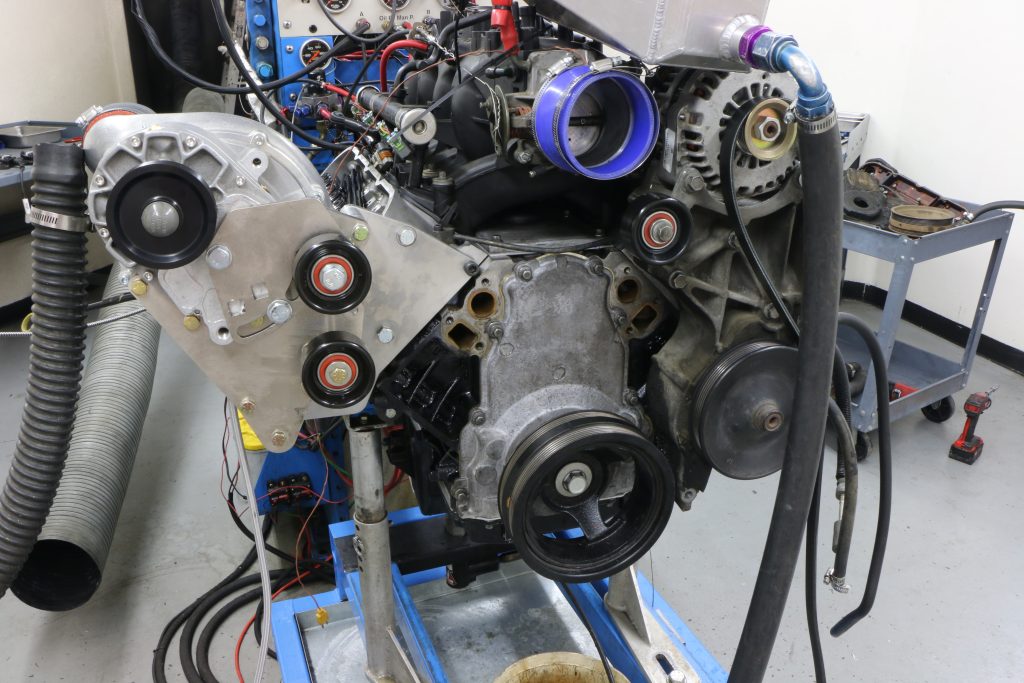

Further illustrating the concept of blower combos responding to more aggressive cam timing is one of many tests run on a 5.3L LS.

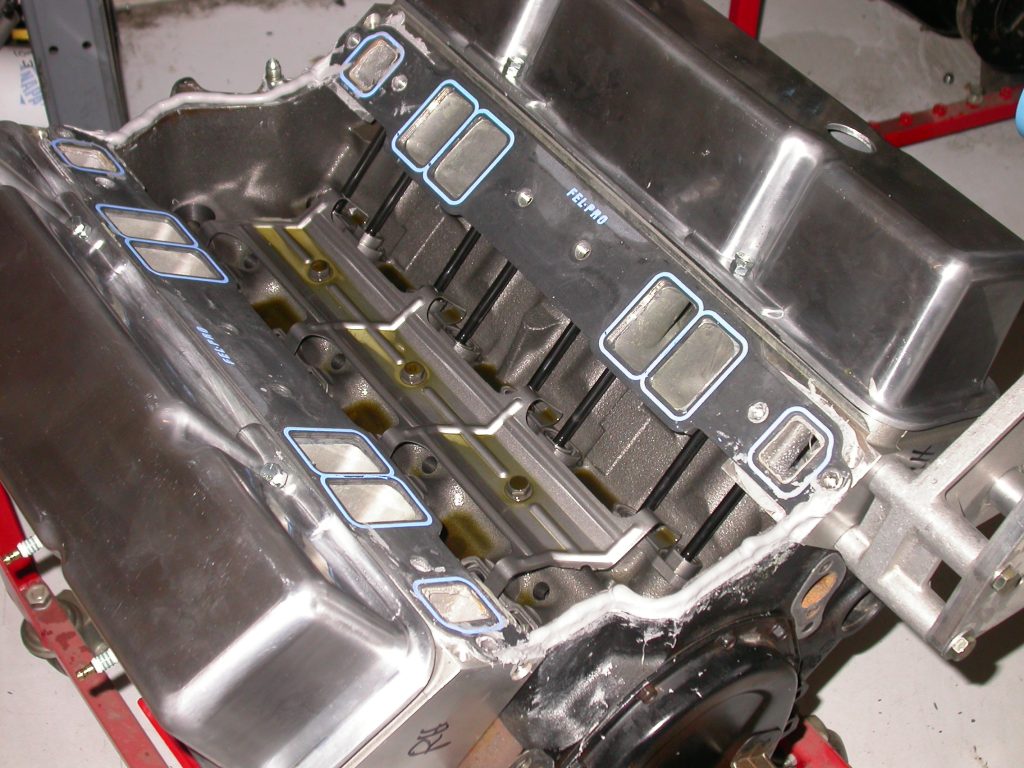

The 5.3L test motor was supplied by the guys at Strictly Performance. The boost-ready motor featured a stock block, Gen. 4 rods and hard-anodized, cast pistons with the (all-important) ring gap. The 5.3L was equipped with 706 heads secured with MLS head gaskets and ARP head studs.

While stock heads would certainly work, these 706 heads had been given the once over by the guys at Katech Engines. Katech offers affordable porting options for stock heads, with additional options to further increase the flow and power potential. For our cam test, the heads were equipped with a dual spring package from Brian Tooley Racing. The heads were run with stock rockers and hardened pushrods.

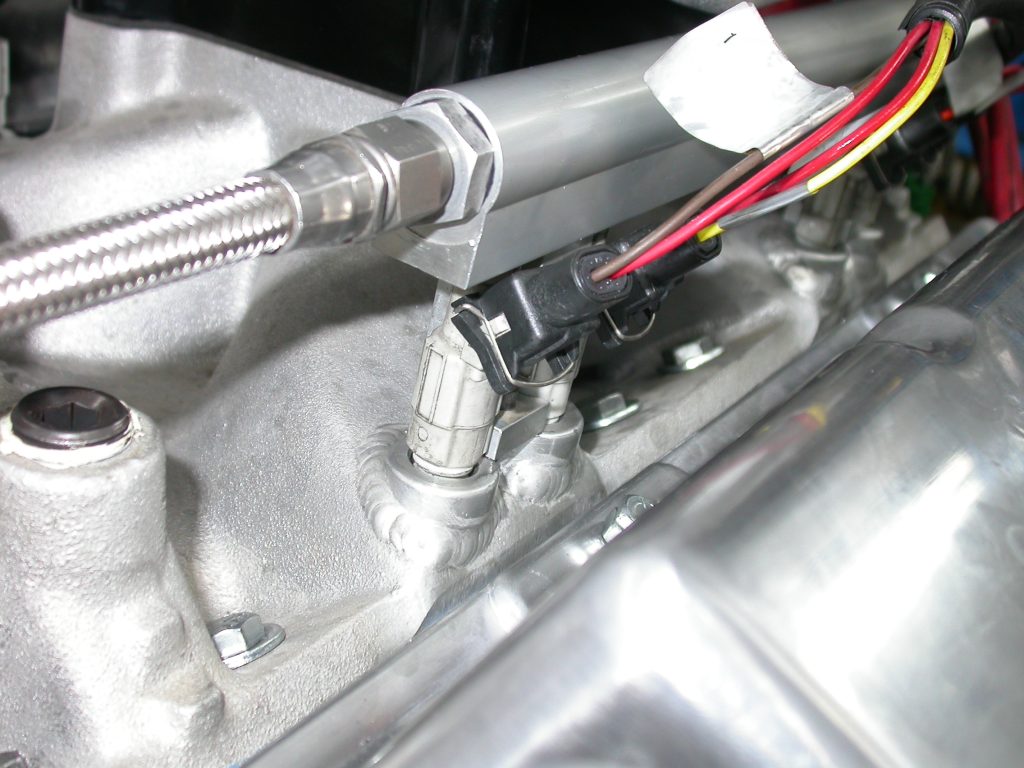

Topping the heads was a factory (early) truck intake with a stock throttle body. Naturally the injectors were upgraded from stock to 80 pounders for the boosted power output. Fuel flow is a critical element when it comes to making power. The stock 25 pound injectors won’t support much more than 400 hp NA, and even less under boost.

For the first test, the supercharged 5.3L was equipped with a factory LS9 cam.

It should be noted that the cam test illustrated here is but one of many comparisons run on this test motor, as we ran this motor NA with different fuels (91 and E85), with a number of different cams (NA and boosted) and intercooled vs. non-intercooled.

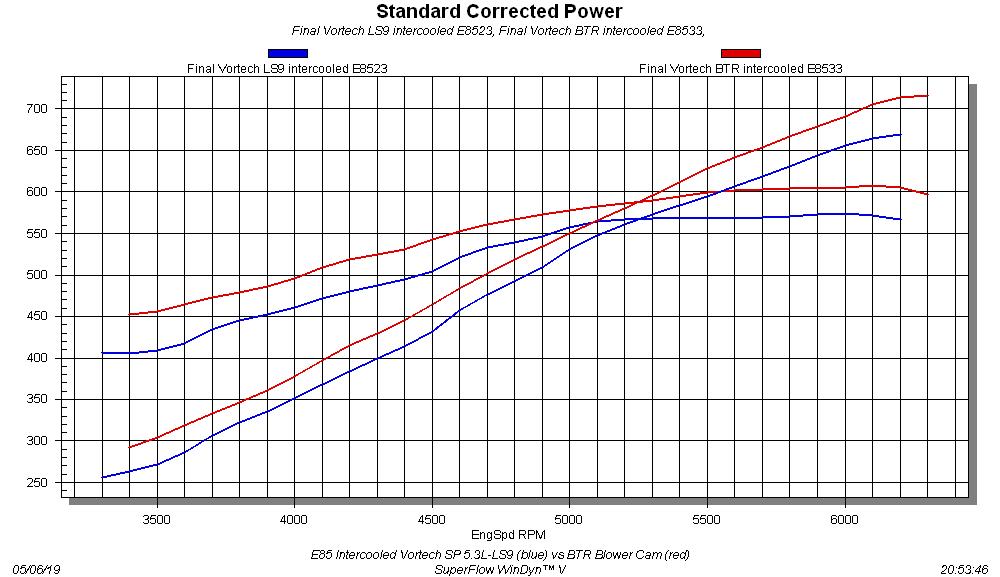

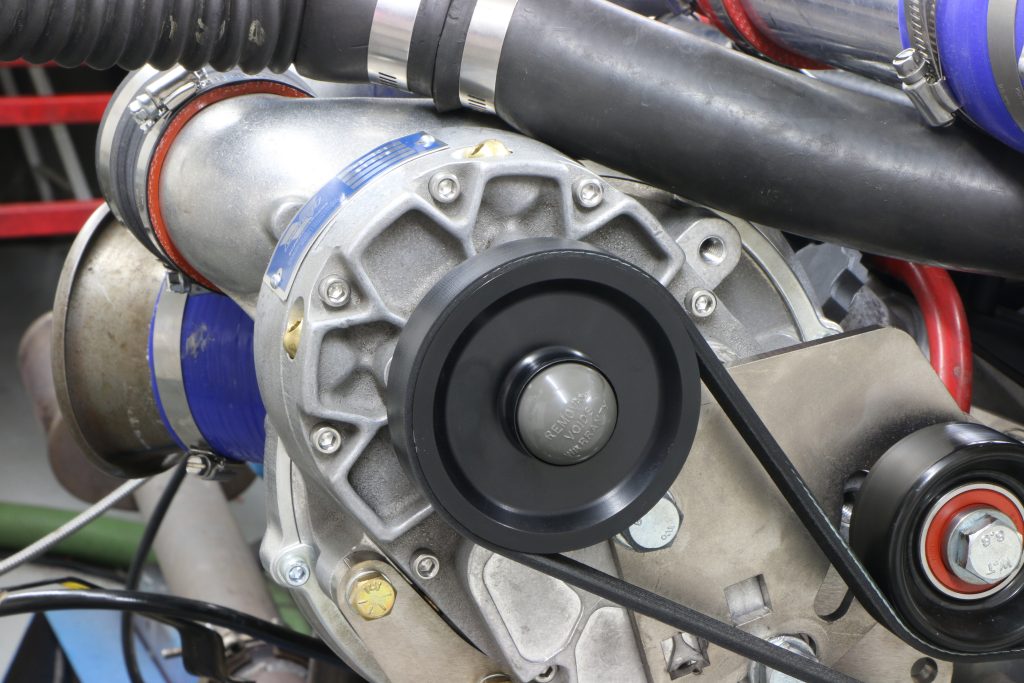

For our cam test comparing the LS9 to the BTR blower cam (.613/.596 lift split, 227/244, 115 LSA), the motor was configured with an air-to-water intercooler and run on E85 fuel. Both cams were run with the same A/F and timing to minimizes power changes based on other variables. The 5.3L was equipped with a Vortech S-trim supercharger using a 3.6 inch blower pulley.

Run in this manner with the LS9 cam, the Vortech supercharged 5.3L produced 669 hp at 6,200 rpm and 573 lb.-ft. of torque at 5,900 rpm. The peak boost registered at 6,200 rpm was 8.5 psi.

After back up runs repeated the power numbers, we replaced the LS9 cam with the BTR blower cam. Run with the BTR cam, the Vortech 5.3L produced peak numbers of 716 hp at 6,300 rpm and 607 lb.-ft. of torque at 6,100 rpm. The peak boost dropped slightly to 8.1 psi with the bigger cam.

More power with less boost—it’s almost like blowers like bigger cams!

Comments