“Three questions I get: ‘Is it hot? Is it loud? Is it fast?’ Yeah.”

John Black is a retired aviation maintenance instructor who, with his ingenuity and dedication to speed, has created an autocross weapon that manages to address one of the safety issues that dogged early Corvairs: it handles—really handles.

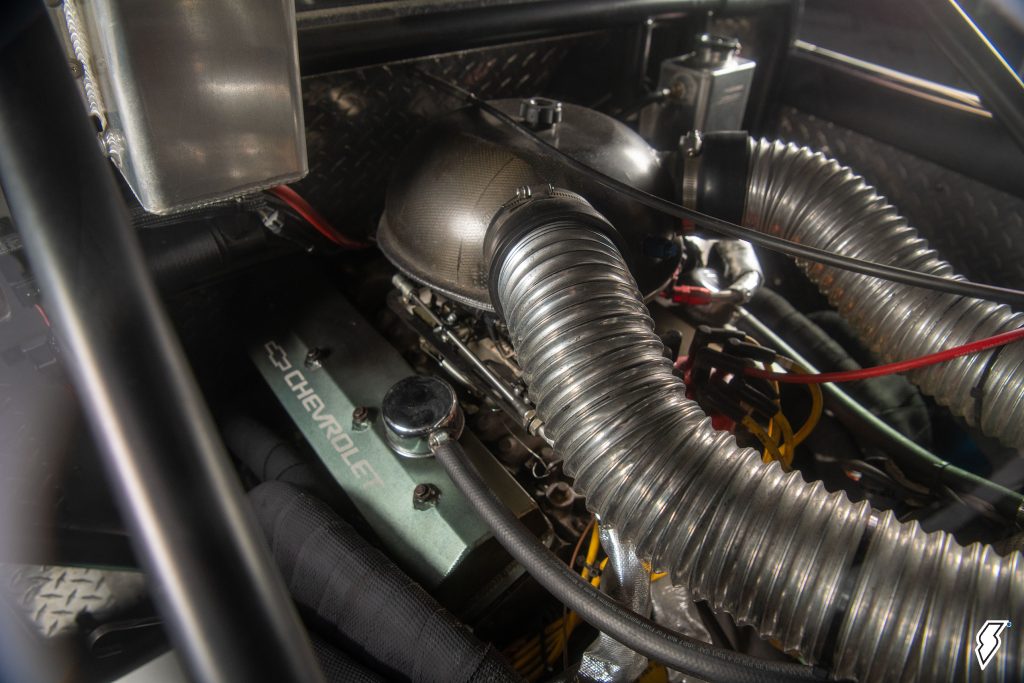

While Ralph Nader, author of the 1965 book “Unsafe at Any Speed”, might appreciate some of the improvements John’s made to his 1966 Corvair, he’d probably find others a bit unnecessary. With a stroked, 427ci small block Chevy occupying the space where the backseat used to be, it performs more like a rowdy muscle car than GM’s thrifty, air-cooled compact!

A mid-engined Corvair that’s durable and well-sorted enough to stand up to autocross abuse, the HOT ROD Power Tour, and a couple thousand street miles a year doesn’t just happen, though. Surprisingly, it started as a senior project for John’s son, Cory, who was already a Corvair fan, having daily driven a Yenko Stinger clone for a couple of years in high school.

“In Pittsburgh, the seniors have to do a project, and it can be anything from painting a dugout, to doing community service, to building a car,” John explained. “He came to me and said, ‘What about a V8 Corvair?’ and I immediately remembered an article I read when I was around 16 years old about the Crown conversion cars,” he said, referring to Crown Engineering, the California company that built kits to V8 swap Corvairs.

John also saw the Corvair project, and autocross, as a new hobby for Cory, a competitive motocross racer who had to give up riding following serious injury. “I was really trying to get Cory out of his funk, because he had lost motocross…and he came up with this idea,” John explained, gesturing at the Corvair.

V8-swapped Corvairs are fairly uncommon, but back in 2003, John found a couple in short order. The first was in a warehouse in Pittsburgh and had been converted to V8 power when it was brand new using a rare, high-revving DZ 302 engine from a 1969 Camaro Z/28. However, as is so often the case with cars languishing in storage, the owner couldn’t be convinced to sell it. But, the very next day, this car popped up on Craigslist.

It was rust-free—critical on a car with a reputation for rot—but far from ready to roll. “It was a start to a homemade Crown swap. It had a dead 350 in it with a wiped cam. I bought it from a guy in Ohio who was a drag racer. He had put the transmission and differential together; he had a Crown adapter. He had some rather sketchy attachments from the engine to the car. I redid his mounting—well, I redid almost everything. There’s a few of his welds still left,” John laughed. “It had a parking sticker on the windshield from the college I went to in San Diego. The guy had bought it from the guy who brought it out from California, so it was destined to be our car,” he added.

A nine-month build got it on the road in 2004, in time for Cory’s graduation. But that was only the beginning. “It had a mild 350 in it at that time, then I stumbled on a 383 the guy had built wrong and stuck a valve, and I got it for cheap. Cory went through it; it was his first engine build. It was a pretty strong runner.”

But that 383 revealed a critical weakness: the stock differential was never meant to cope with V8 power. The car came equipped with a Powerglide transmission, which John saw as ideal for autocross, and hoped would be easier on the OE differential than a manual. He was half right; the car tops out at 65 mph in first, making shifting unnecessary at pretty much any autocross event. But even the relatively gentle automatic was splitting Corvair differential housings. There was no way it was going to work with the 427, built with a bulletproof Dart block, packed with top-quality components, and pumping out an estimated 550 horsepower.

“I got tired of babying it off the line and it’s like, ‘Nah. I gotta come up with a better idea.’ Somebody had rumored that the splines were the same in a Powerglide as a C5 Corvette differential, and that sparked me enough to find a $100 eBay buy—2.73 gears, I think—nobody wanted it, but I just wanted to fit it,” John said. It turned out the rumors were true. “Female on the pinion gear, and the (transmission) output shaft’s 27 splines; same diameter. It was really cool when I slid it on. It went ‘tink,’ meaning I got full engagement. There was about three-quarters of an inch space, so I made a one-inch spacer. It’s like, ‘You gotta be kidding me. This is going too easy!’” he recalled, laughing.

While the beefier C5 differential (now a 3.42:1, limited-slip unit) solved a problem, it created a new one. “I had to make a whole girdle around the differential because that carries all the suspension components. That was kinda tricky, too,” he said.

The Corvair control arms were reinforced and modified to accept Corvette wheel bearing housings. What he ended up with was a modified trailing arm setup with four links for lateral positioning. Geometry was determined through educated guesses and trial-and-error. “I laid out all the suspension geometry for roll center and bump steer. I had it laid out on my garage floor full-scale, made of wood. My son was going to engineering school, and he came home and he’s looking at what I’m doing and he’s taking pictures. I said, ‘What’re you taking pictures of?’ He said, ‘I gotta show my professor. He’s not gonna believe what you’re up to,” John said.

The front suspension and steering didn’t require as much re-engineering as the rear, but they’re far from conventional. A steering rack from a Dodge Intrepid sedan was installed, and it drives a box tube “walking beam,” as John describes it, that rides on Boeing 737 flap track bearings. This allowed length adjustment for perfect steering geometry. “I’ve got it exactly set for zero bump steer in the front. It’s two-and-a-half turns lock-to-lock with a 12-inch steering wheel, and it powers those front tires easily.” Cut-down springs from a Mercury Bobcat wagon support the front end, and the only letdown is the stock ball joints. “Yeah, I’m still chasing ball joints. Those big tires wear out front ball joints pretty fast,” John lamented.

Completing the chassis is a set of NOS 1960s Koni shocks, Wilwood four-piston calipers squeezing an oddball combination of C6 Corvette and Cadillac rotors, and Trans Am-inspired E-T Mags 18-inch wheels with massive 315/30ZR18 front and 335/30ZR18 rear Hoosier A7 autocross tires.

The Corvair’s body is just as unique as what’s underneath it. The most obvious modifications, the fender flares, were grafted onto the car around 2017 in a quest to fit larger tires. “The biggest tires I could put on it were Hoosier A7s from a Miata,” John said.

The metal for the flares came from the most unlikely source: a 1980 Toyota Hilux pickup. “Front fenders; I bought three front left and three front right, and that’s what I made all four out of…I sectioned them and pieced in a filler panel here,” John explained, pointing at the seamlessly widened front fender.

Just as eye-catching is the wild roof scoop that was crafted from a fiberglass mini sprint car hood. John’s not sure if he likes it (“Some days I look at it and I think, ‘What was I thinking?’”), but it performs the critical task of feeding air to a homemade airbox atop the Holley Sniper EFI throttle body.

Of course, that airbox has a story, too. “That hat I made from my wife Claudia’s wok while she was at work, thinking that I could bake it; it’s carbon fiber. I used to make carbon fiber parts for motorcycles to pay for our racing. I laid it up, I baked it, and then I tried to get it out and it wouldn’t come out! I ruined her wok getting it out. She was not happy!” he laughed.

While John’s not sure about the scoop, he’s a fan of the bumper-free front end, a modification that was done by accident—literally. “We were in Helen, GA, for the Corvair Springfest. They had a parking lot that was maybe twice as big as this (60 ft. x 112 ft.) building, and that’s where we were racing. Cory went out for his first run, and he comes in and says, ‘Be careful; when you’re braking for that left-hander up there, you’re headed right for that fence and there’s a curb there.’ And then, two runs later, he drives right up over the curb, all the wheels are locked up, and BOOM! knocked down the fence. Two thousand dollars later—we had to pay for the fence—and then another two thousand bucks for the front end work, but that was when I took the front bumper off and redid the valence. I like it. It reminds me a little bit of the GT350R,” he said.

The fiberglass hood is ducted to facilitate airflow through the massive F-250 diesel radiator, and fiberglass doors and decklid contribute to the svelte package. The car weighs in at just 2,840 lbs. with a tank of gas, and has ideal front/rear balance, according to one of John’s heroes, legendary Chaparral race car designer and driver Jim Hall.

“If you read any documents from Jim Hall, he said a rear-engine race car—if you’re setting it up for any kind of handling—48/52, that’s what you want. And when I finally bit the bullet and bought scales, ‘Holy cow! It’s exactly what he said!’ Not by design, by chance,” he said.

The snug interior is outfitted with sport seats, custom carbon fiber door cards, and a roll cage designed for a 1967 Chevy and modified to fit the Corvair. It also provides access to the 427. “To change the engine, it comes in through the door. I don’t even have to take the seat out. I fold it down, push it forward. You get the car up on jackstands so that the arm on the cherry picker can come in straight, and it comes right out,” John explained.

The one thing the interior doesn’t feature is air conditioning, which became an issue during the 2023 HOT ROD Power Tour. “It had to be 140 degrees inside that car. One day it was rainy out and it was about 95 degrees, so it was 100% humidity. I have these removable side windows that I carry with me, and I put the windows in because it was raining. We’re driving down the road with the doors open—holding the doors open—trying to get air because we’re both dying!” he recalled, laughing.

Making a 550 horsepower Corvair work this well means solving problems, and John’s up to the challenge. “I made it to do a job. I didn’t make it to show. It’s all garage stuff. I look at some of these show cars and the work that the guys do and I get embarrassed but, you know what? I’m structurally sound. It’s held together for a long time. I think that its efficacy has been proven with the Power Tour,” he said. And it’s hard to find fault with the years of modification, refinement, and improvement that continue to this day.

And in case you’re wondering where the CorVin8er name came from, John, of course, has a story. “That was my buddy who was my son’s mentor on the project. He was the most knowledgeable hot rod guy I knew at the time. Kenny Collins is his name. He was the one who convinced me that every build needs a name. So, we’re just bouncing ideas at lunch one day at work, and he says, ‘I think I got it: CorVin8er. V8 in the middle of the car. Corv: Cory…Corvair…Ralph Nader.’ I said, ‘Yeah, you got it! That’s it!’”

Photography By: Todd Biss Productions

Art Direction By: Lance Nemes

1966 Chevy Corvair Monza Fast Specs

Owner: John Black – Moon Township, PA

ENGINE

- Dart SHP 427 small block Chevy (4.125″ bore)

- SCAT 4340 forged crankshaft (4.000″ stroke)

- Eagle H-beam rods

- Mahle forged pistons

- Clevite rod and main bearings

- TCI Rattler harmonic balancer

- Melling oil pump

- Canton Racing Products oil pan

- Patriot Performance aluminum cylinder heads

- Howards hydraulic roller camshaft, lifters, and pushrods

- Summit Racing™ 1.5 ratio aluminum roller rocker arms

- COMP Cams® dual valve springs

- Holley valve covers

- ARP hardware

- Machine work by CNC-Motorsports, Brookings, SD

INDUCTION & FUEL

- Holley Sniper EFI

- Edelbrock Performer RPM intake manifold

- Holley Blue electric fuel pump

- FiTech surge tank

IGNITION & ELECTRICAL

- MSD Pro-Billet distributor

- MSD 6AL ignition box

- MSD Blaster High-Vibration ignition coil

- ACCEL 8mm ignition wires

- Summit Racing™ 100 amp alternator

EXHAUST

- Schoenfeld 1-3/4″ circle track headers

- Cherry Bomb mufflers

- 2-1/2″ tubing, X-pipe

DRIVELINE

- GM Powerglide by Abruzzi Racing Transmissions, Warren, OH

- Boss Hog 2,800 rpm stall torque converter

- Hurst Quarter Stick shifter

- C5 Corvette Z06 rear end with Quaife limited-slip differential, 3.42:1 ratio

COOLING

- 1997 Ford F-250 diesel radiator, 14″ electric fans

SUSPENSION & STEERING

- Independent front with Mercury Bobcat wagon springs, Chrysler LH steering rack, and 1-1/4″ stock car sway bar

- Trailing arm rear with lateral links and C4 Corvette sway bar

- Koni shock absorbers

BRAKES

- Wilwood Dynalite 4-piston calipers (front/rear)

- 12.9″ C6 Corvette rear rotors (front), 10.5″ Cadillac front rotors (rear)

- Wilwood master cylinder with GM truck Hydroboost

WHEELS & TIRES

- E-T Mags LT-III 18″ x 12″

- Hoosier A7 315/30ZR18 (front), 335/30ZR18 (rear)

BODY & PAINT

- Custom fender flares, front valence, and roof scoop; fiberglass hood, doors, and decklid; LEXAN™ rear window

- Metalwork and modifications by John Black

- Arctic White paint by Gnu’s Body Works, Freedom, PA

INTERIOR

- Custom roll cage with swing-out door bars

- Simpson harnesses

- Carbon fiber door cards by John Black

Special thanks to: My wife Claudia, for putting up with this crazy hobby for the last 45 years; my son Cory; Gary and Collin Snair at Gnu’s Body Works; Bob Rippey for TIG welding the cage; Ken Collins for parts and the CorVin8er name

Fantastic write-up. I’d like to take this car out, or take a ride. Probably would be more than an exciting ride.

There was a similar car built in the Atlanta area with a 434 SBC, Jerico trans and C-5 diff. It was vintage road raced for many years and pissed off a lot of Porsche drivers… and others!

There’s another turboLS, powerglide car with C-5 diff that is a serious bad-ass street car also in the Atlanta area.

Fantastic! Something like this has been a dream of mine even before Vietnam!!