Axles are one of the unsung heroes of your performance vehicle. They do an incredibly difficult job, but they aren’t something we think about.

Rarely, does someone brag or show off a set of axles, much like you’d do for a blower, cool intake, or a set of stainless headers or sheetmetal valve covers.

Nevertheless, the job of transferring the torque from the differential to the wheels is critical. When your axles work you get acceleration, when they fail you go nowhere. That’s why most performance applications will require a set of aftermarket axles.

It’s for safety and the peace of mind.

In fact, only after torching a weak axle do you realize the importance of having a robust set of sticks in there. But like bellybuttons that are of sight out of mind, axles often go unnoticed during a build—which is why we prescribe to the notion that performance axles are one of those things you should add before you need them.

Talking Torque: Why Performance Axles for Drag Racing?

We know the job of the axles is to turn power (torque) into forward motion, but did you know that a 1,000 horsepower vehicle can channel over 10,000 ft.-lbs. during launch?

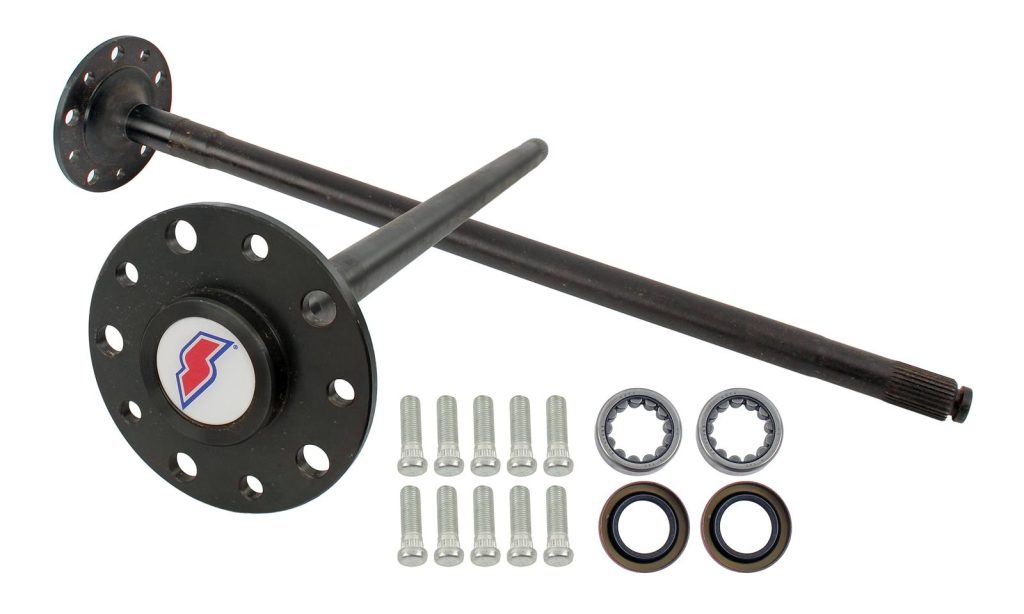

Thankfully, SummitRacing.com offers a wide range of aftermarket axles for most performance applications and for a variety of spline counts. Aftermarket performance axles can handle a lot more power (torque) than stock axles, and in some cases, be lighter and stronger.

As you’ll see, there is no silver bullet to creating a strong drag racing axle, rather, it’s about combining upgraded materials, design and processes to create the best axle for the job. Improvements often come by way of stronger materials and the heat treating process.

Lots of technology goes into the metallurgy of drag racing axles, and every company has its own secret sauce, but in essence, there are four main types of materials. Carbon 1055 or 1552 steel is common in OEM applications. Next up the food chain are aftermarket induction-hardened 1552 carbon steel units for street/strip applications. There’s through-hardened (or thru-hardened) steel alloy units often made from 4340 that are designed for drag racing applications, and finally, through-hardened 300M alloy steel for the big dog drag cars.

Hy-Tuf Drag Racing Axles from Strange are ultra-strength alloy containing low carbon, high manganese, high nickel, and high molybdenum steels. They also feature a thru-hardening manufacturing process, which yields an extreme capacity for tensile strength of 240,000 psi. At the same time—because of the low carbon content of Hy-Tuf, the axle remains relatively ductile. Some degree of ductility is necessary in high-performance and racing applications.

Alloy Street/Strip Axles from Strange are precision CNC-machined from premium forged alloy steel and then induction hardened to resist bending loads and greater flexibility. This is especially important when axles are intended for use in street applications.

The induction hardening process involves pulling the axle through powerful electrical coils that sequentially heat and quench the shaft. This creates an extremely ductile axle because the case is substantially hardened while the core of the axle remains relatively soft. This type of induction hardening is used to treat all Strange premium alloy steel axles designed to survive the bending loads associated with street usage.

Heat-Treating

Again, avoiding the engineering manual here, just know that companies employ a wide variety of heat-treating processes that can greatly increase the strength of an axle. For the sake of cost and design parameters, OEM axles typically only receive induction hardening out to the bearing surface, which the axles softer than the rest of the unit. Induction hardening is where the axle passes through an electromagnetic coil that excites a strong current inside the shaft, heating it so that the core remains somewhat soft, but the outside hardness substantially increases.

Splines & Diameter

We’re clumping these together because it’s hard to talk about one without the other. Simply put, increasing the diameter of the axle increases its strength, but with that normally comes an increased spline count. These days 31 to 35 spline axles are commonplace at the drag strip, but step up to serious horsepower and you’ll need 40 spline or more units. More splines give the axles more surface area to better distribute the loads between the differential or spool and the axles.

Additionally, it’s not just about the spline count, it’s also about the shape and depth of the splines. As you already know, the outermost portion (the peak of the spline) of the spline dictates the diameter of the axle, but the innermost portion of the spine (the bottom of the grooves), known as the minor diameter also plays a larger part in overall strength. Let us also not forget the shape of the splines, as the pressure angle can vary from 30 degrees on street/strip setups to 60 degrees on racing applications because of the shorter spline and larger minor diameter.

Wise words from Strange Engineering on splines: “If you plan to make a differential carrier change in your street machine, Strange strongly recommends that you upgrade factory-sized axles to at least a 31 spline axle and carrier configuration. The price of the 31 spline axle components is no more than the 28 or 30 spline and the benefits are immeasurable. This will yield a stronger and more durable rear end,” said JC Cascio of Strange.

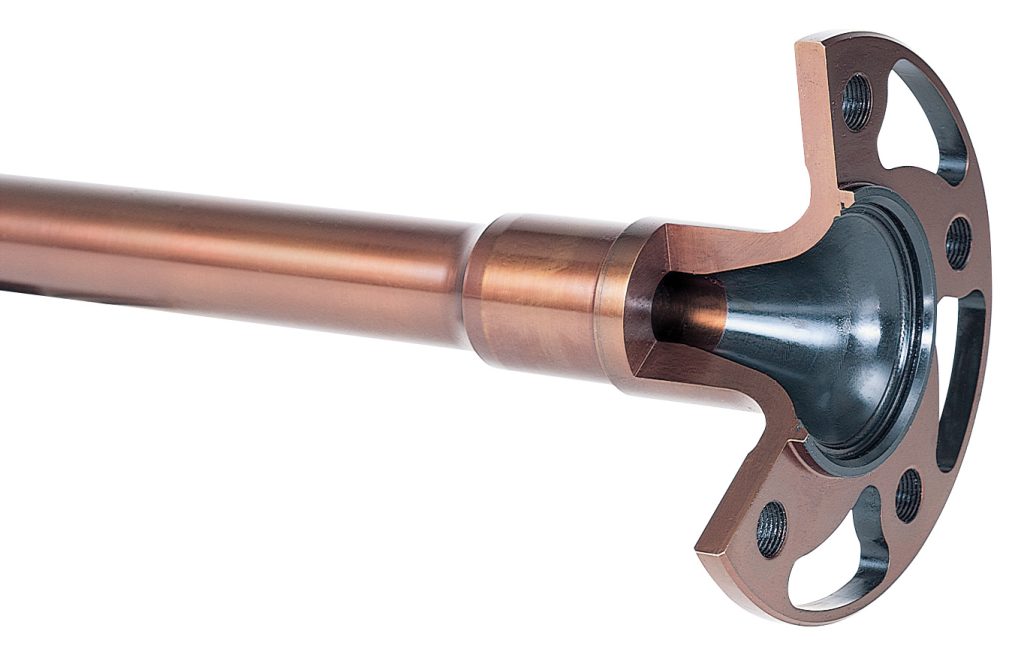

Flange Thickness & Wheel Studs

Many OEM axles feature flange widths of around 3/4 inch that accommodate soft pressed-in wheels studs ranging in thickness from 7/16 inch to 1/2 inch that are more than up to the task of light drag racing at near stock power levels while on street tires. Aftermarket companies like Strange, Mark Williams, Moser, and Summit Racing offer 3/4 inch or larger flanges that are drilled and tapped to accept monster screw-in 1/2 inch or 5/8 inch lugs or drive studs—these upgrades greatly increase their strength.

Another way to increase the durability of a street/strip rear is with a C-Clip Eliminator Kit. As the name implies, this eliminates the axle retaining C-clips from the differential end of the axles and replaces it with a bearing that secured to the end of the axle housing. These require modification to the housing but add strength. They are common on 12 bolt GM and 8.8 Ford applications.

Many NHRA Classes require use of a C-Clip Eliminator-type axle bearing, since under the extreme circumstances of drag racing axles that are retained using only a small C-clip can lead to catastrophic results. If the C-clip breaks or comes off, the wheel and the entire axle may separate from the differential housing and the vehicle.

How Can You Lighten Axles Without Compromising Strength?

There are numerous ways to decrease weight on an axle while also preserving its strength, and the first and most common technique has the coolest name: is Gun-Drilling.

This is essentially the process of removing the core of the axle (along with a certain amount of flange material) and leaving a 7/8 inch hole in the center of the axle shaft. This is done to reduce rotating weight and results in roughly one pound of weight reduction per foot of axle drilled.

Very interesting article, thank you