I have a 355ci small block Chevy engine in my pickup. It has a set of those triple triangle Vortec heads, and I just added a bigger COMP Cams 268H Xtreme Energy flat tappet hydraulic cam and a set of 1.6:1 roller tip rocker arms. I decided to spin the engine over with the intake manifold off to make sure oil was getting to the rockers. The engine spun over a few times and I saw at least four pushrods bend right before my eyes! I’m pretty sure we adjusted the rockers correctly. I’m not an engine builder but I’m pretty sure we installed the cam and adjusted the rockers correctly so I’m not sure why the pushrods bent. Do I need different pushrods?

D.W.

You’re lucky that you just spun the engine over a few times with the starter and did not attempt to start the engine. This hopefully limited the damage to just the pushrods and probably most, if not all, of the valve guide seals.

There are several issues here. We will assume that you’re running a set of stock Vortec cylinder heads and not aftermarket versions like the ones available through Summit Racing. The stock Vortec heads were originally designed for pickup truck engines using a short duration camshaft with around 0.450-inch of valve lift. This amount of lift provided 0.050-inch of valve seal-to-retainer clearance.

This is important because the specs on your Comp Xtreme Energy camshaft list the valve lift at 0.477-inch on the intake side and 0.480-inch for the exhaust using a 1.5:1 rocker arm ratio. This combination puts the retainer very close to the valve seal. Using 1.6:1 rockers adds 0.030-inch of valve lift, putting total lift past 0.500-inch for both valves. This creates a bad situation where the bottom of the valve spring retainers will hit the valve seals as the lifters continue their travel. This is probably what bent the pushrods.

Simply put, you need to add more clearance between the valve spring retainers and the valve guide seals. Before we go into ways to do this, we suggest closely inspecting all valvetrain components, especially the rocker arms and rocker studs. It’s possible that if enough force was created, one or more rocker studs could be bent. You can also assume that all the pushrods will need to be replaced.

Since the heads are installed on the engine, the quickest and easiest way to increase retainer-to-valve guide-seal clearance is to change the valve springs and retainers. COMP Cams makes a beehive-style spring designed for LS engines that will work very well on your small block. These springs use a smaller retainer that is slightly taller on the spring, which offers additional clearance. Another option is a set of Summit Racing LS6 valve springs with slightly softer specs and a lower price tag.

Our parts list includes retainers, locks, and new valve guide seals to complete the valve spring conversion. The retainers and locks are made for use with the 11/32-inch (0.343-inch) valve stems found on older small block Chevy engines versus the 8mm (0.315-inch) LS-style valve stems. You must always match retainers and locks to properly locate the retainers on the valve stem.

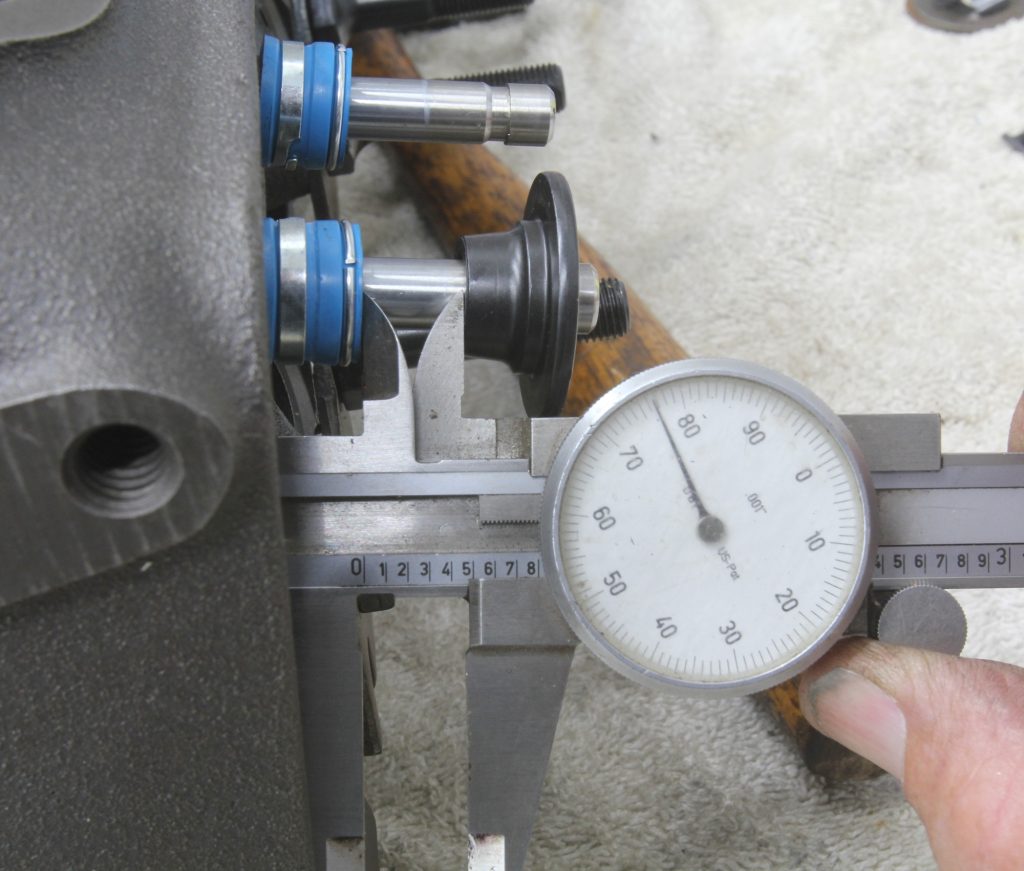

You will also need to verify the spring installed height. Installed height is the distance from the spring seat in the head to the bottom of the retainer where the spring makes contact. You can use a machinist’s scale to measure, but an inexpensive height micrometer makes the job much easier.

We recommend installing springs at the tallest installed height you can generate. Most factory Vortec heads come with springs with 1.750 inches of installed height, but we suggest using springs that provide 1.800 inches of installed height. This improves retainer-to-seal clearance and reduces spring load. That will help reduce the chances of killing a camshaft lobe during break-in.

Using a set of 1.5:1 rocker arms instead of the 1.6 ratio rockers you have now will also help improve the retainer-to-seal clearance and won’t dramatically affect torque and horsepower. You will still need to replace the valve springs to gain the necessary retainer-to-seal clearance.

It’s important to mention that Vortec cylinder heads use a guided rocker arm as opposed to rocker arms that use pushrod guide plates. Guided rockers have two small bumps or rails that straddle the valve tip. This properly centers the rockers over the valve tips. Make sure there is sufficient valve tip height to keep the rails from contacting the retainer. If this happens, the valve stem locks could unload and cause a valve to drop.

If you want to use standard rocker arms, you’ll have to convert to screw-in rocker studs and guide plates. This will require taking the heads to the machine shop. They will remove the stock press-in studs, machine the stud bosses flat, then drill and tap them to accept the screw-in studs and guide plates. The cost of this machine work might be very close to the cost of buying another set of guided rocker arms.

All this involves more work than you anticipated, but it will solve your bent pushrod problem. We assume that stock 7.80-inch-long pushrods will be the proper length, but double-check the length just to be sure.

Parts List

COMP Cams Beehive Valve Springs CCA-26915-16

COMP Cams Valve Spring Retainers CCA-774-16

COMP Cams Valve Locks CCA-601-16

Summit Racing™ LS6-Style Valve Springs SUM-174002

Summit Racing™ Valve Spring Retainers SUM-174003-3

Trick Flow Valve Locks TFS-51400444

Fel-Pro Valve Stem Seals FEL-SS72861

Reworking my chevy 383 stroker to be much more a streetable motor replacing the cam system..Engine currently runs with a solid Lunati roller cam, with modified bowtie heads, 12:1 compression, 1.5 rocker lifters. Thinking about a Comp CCA 12-473-44 Hyd Retro fit, if it will stand up to the current engine specifications ?? Using a TEAM G intake with a 1 inch spacer and Dominator Carb.?? Will return a Comp Extre.me Cam not used still in the container box to Summit?? Any suggestions. Engine going in to a 96 Chevy Silverado back by a five speed sta dard tranny…