There are many reasons to update your vehicle’s fuel system: increased fuel demands from a new build, higher pressure requirements due to a carburetor-to-EFI swap, and more.

Correct pump placement, filter type, proper connections, and fuel line routing allow the pump to operate at maximum efficiency, improving the fuel system’s overall performance and reducing noise.

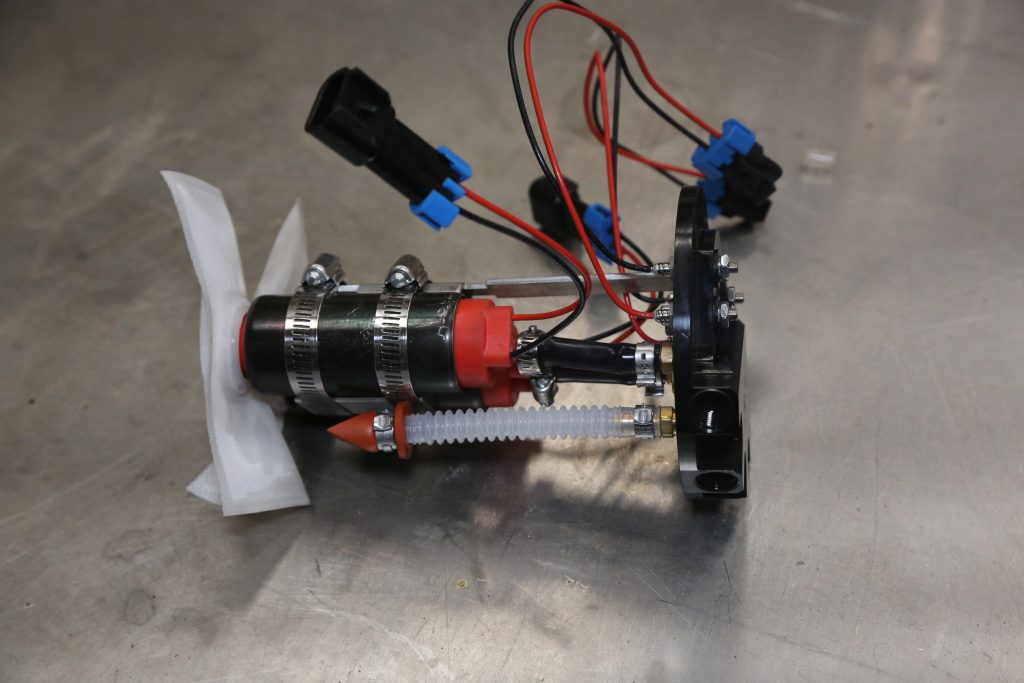

Electric in-tank fuel pumps should be used whenever possible, since the surrounding fuel helps manage noise, vibration, and heat better than an external pump. External electric fuel pumps are noisier but may be better suited to your application, depending on the situation.

But keep in mind that there are ways to reduce fuel system noise regardless of the type of pump you choose.

Fuel Pump Installation Best Practices

After choosing a fuel pump (refer to the chart below for guidance), the next step is determining where to place system components. External pumps should always be positioned at or below the bottom level of the fuel tank to ensure proper priming and a consistent fuel supply.

They should be close to the tank to push fuel up to the engine—not pull it.

Pumps typically specify recommended filter sizes, but in most cases, using a 100-micron pre-filter will prevent dirt or debris from damaging the pump and ensure fuel system longevity.

When installing pumps and fuel filters, use vibration mount kits or rubber isolator standoffs to reduce noise transfer. Avoid mounting the pump to sheet metal. Instead, position the pump on the frame or subframe to minimize resonance. Making a sturdy bracket can also help reduce noise if sheet metal mounting is the only option. Hard steel lines, aluminum lines, and stainless steel braided hoses create a metallic junction at the mounting points, transferring vibration into the vehicle.

Using rubber-insulated line clamps and fuel hose with an external nylon jacket, like Summit Racing braided nylon hose, Vibrant Performance nylon braided PTFE hose, or a black-coated stainless braided hose, such as Fragola 6000 Series, can help isolate noise.

Finally, avoid mounting fuel pumps and filters near suspension or exhaust components.

When routing the fuel lines, follow the same path as the factory lines whenever possible, as this is a safe and established route; use heat sleeves when lines must run near the exhaust. Never mount hoses near areas that could get rubbed or pinched by the suspension or jacking points.

Additionally, having a bulkhead connection point under the hood for the feed and return lines is beneficial for future fuel system updates or system diagnostics.

General Guidelines for Fuel Pump Selection

| Fuel Pump Free Flow | Carbureted Engine | Carbureted Engine with Power Adder | Fuel Injected Engine | Fuel Injected Engine with Power Adder |

|---|---|---|---|---|

| 30 gph/114 lph | 350 hp | 300 hp | 300 hp | 250 hp |

| 40 gph/155 lph | 450 hp | 400 hp | 400 hp | 300 hp |

| 50 gph/190 lph | 600 hp | 500 hp | 500 hp | 400 hp |

| 67 gph/255 lph | 750 hp | 650 hp | 650 hp | 500 hp |

| 90 gph/340 lph | 1,000 hp | 850 hp | 850 hp | 600 hp |

| 125 gph/470 lph | 1,300 hp | 1,000 hp | 1,000 hp | 800 hp |

Comments